Industrial method and polycondensation reactor for continuously preparing poly-p-phenylene terephthamide resin with high viscosity

A technology of poly-p-phenylene terephthalamide and an industrial method is applied in the field of continuous preparation of high-viscosity poly-p-phenylene terephthalamide resin, and can solve problems such as unfavorable solvent recovery for environmental protection, low specific viscosity, etc. problems, to achieve the requirements of simplifying the recycling process and equipment, purifying the workshop environment, and improving the viscosity

Active Publication Date: 2011-01-05

中国平煤神马控股集团有限公司

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In this patent, when preparing NMP-CaCl2 solvent, solid industrial CaCl2 is also added to NMP after burning, so the logarithmic viscosity of the resin is not high (the highest is only 5.5). In addition, due to the use of liquid ammonia to neutralize hydrochloric acid , Liquid ammonia is a flammable, explosive, volatile liquid with pungent odor, which is unfavorable to environmental protection and solvent recovery

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

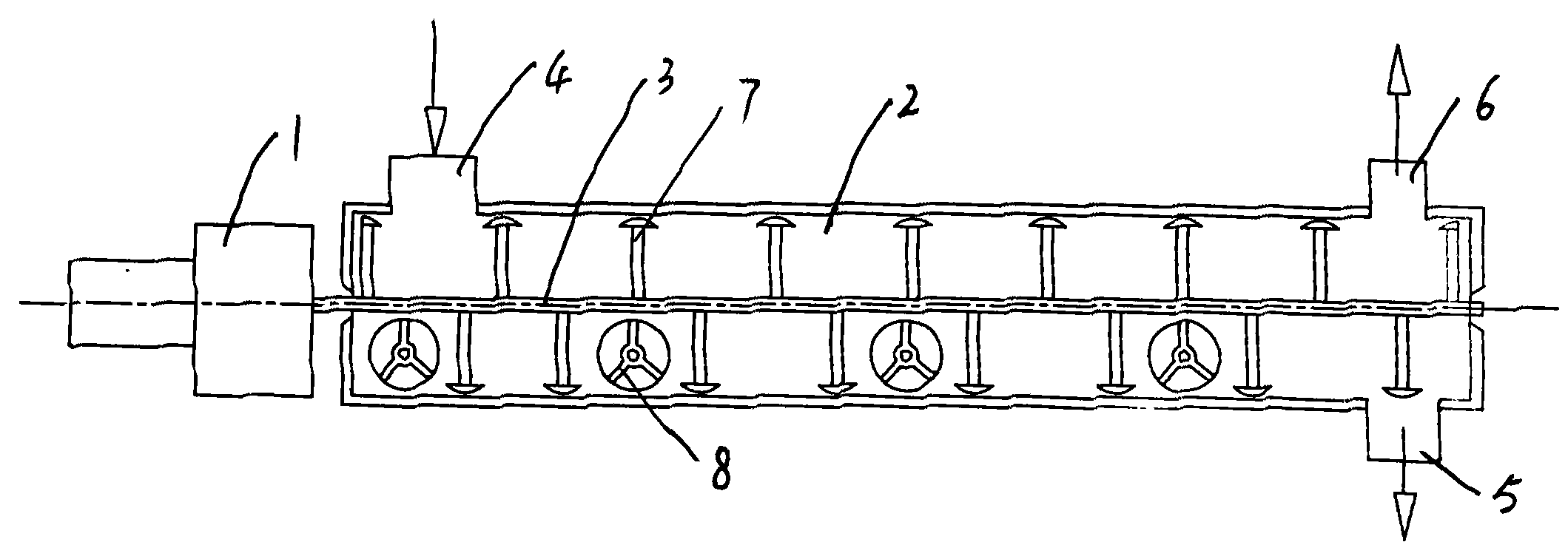

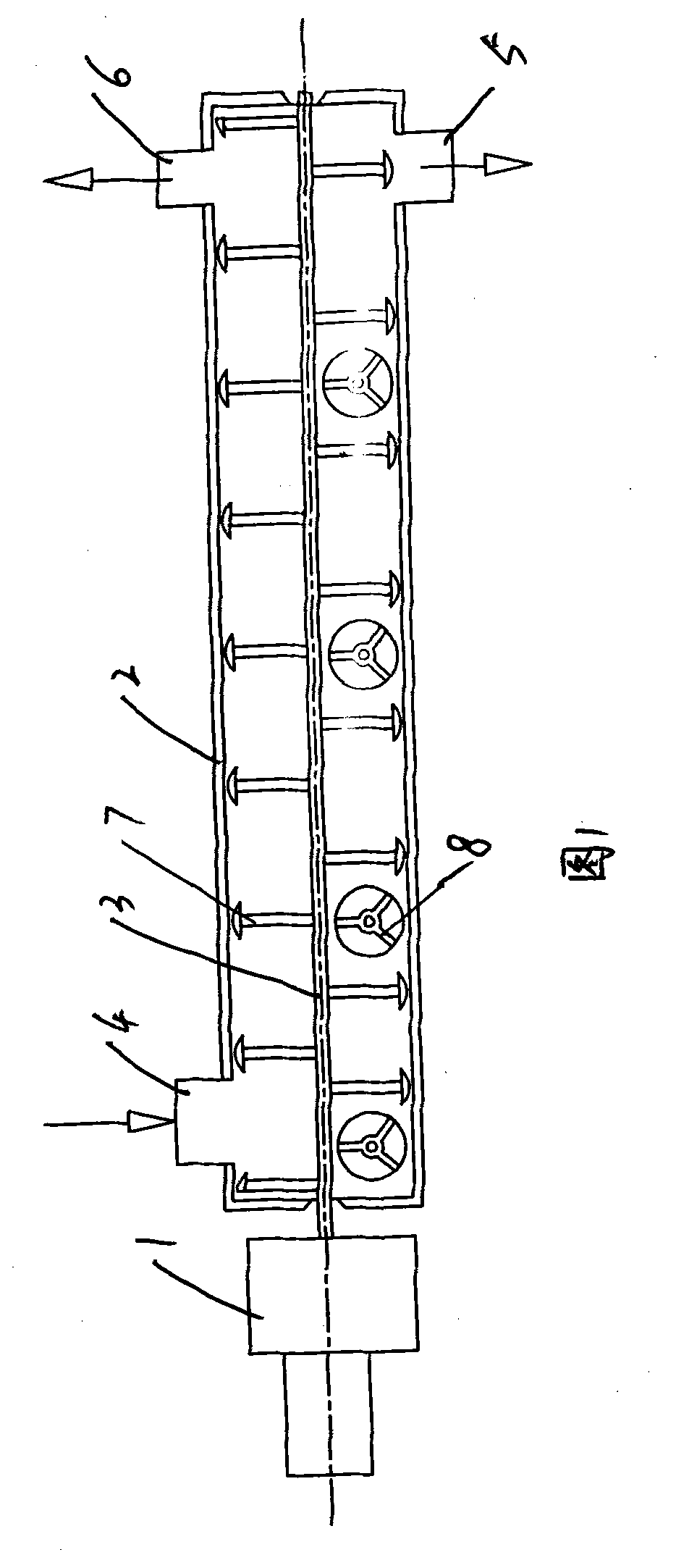

The invention relates to an industrial method and a polycondensation reactor for continuously preparing poly-p-phenylene terephthamide resin with high viscosity, comprising the following steps: (1) compounding a flux into an aqueous solution, then mixing with solvent to remove water by refinement and continuously and stably obtaining a solvent system with the water content conforming to the requirement, wherein the weight percentage of the flux in the solvent system is from 6 percent to 15 percent; (2) performing the polycondensation reaction of para-phenylene diamine (PPD) and terephthalyl chloride (TPC) in the mol ratio of 1.01-1 to 1-1.01 in the solvent system prepared in the step (1), and obtaining a polymer after reaction; and (3) obtaining the poly-p-phenylene terephthamide resin inyellow powder after pulverizing, neutralizing, washing and drying the polymer. By utilizing the method, the adverse effects of weather and operation on the polymerized solvent system water is overcome, and continuous, closed and clean production is realized.

Description

Industrial method and polycondensation reactor for continuous preparation of high-viscosity poly-p-phenylene terephthalamide resin technical field The present invention relates to a kind of industrial method for continuously preparing high-viscosity poly-p-phenylene terephthalamide resin (PPTA), especially relate to the aqueous solution of a kind of co-solvent mixed with water-containing NMP to prepare anhydrous NMP / co-solvent solution, then The industrialized method of polymerizing PPD and TPC in anhydrous solvent to prepare high-viscosity poly-p-phenylene terephthalamide resin. Background technique Polyparaphenylene terephthalamide resin (PPTA) is the raw material for preparing aramid 1414 fiber and pulp. Because of their high strength, high modulus, high temperature resistance, flame retardant and other excellent comprehensive properties, they have been widely used in military, aerospace, sports, communication, chemical and other fields. At present, in the relevant rep...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08G69/28C08G69/46C08G69/32

Inventor 李磊潘育英吕清海马源王良赵辉王建民魏建毅罗亚利冯立伟

Owner 中国平煤神马控股集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com