A Centrifugal Internal Rotating Ring-shaped Bale Forming Device and Method

An inner-rotating and straw bale technology, which is applied in the field of centrifugal inner-rotating annular bale forming devices, can solve problems such as leakage and loss of pasture, rice and wheat straw, and achieve the effects of shortening bale-forming time, reducing leakage loss and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

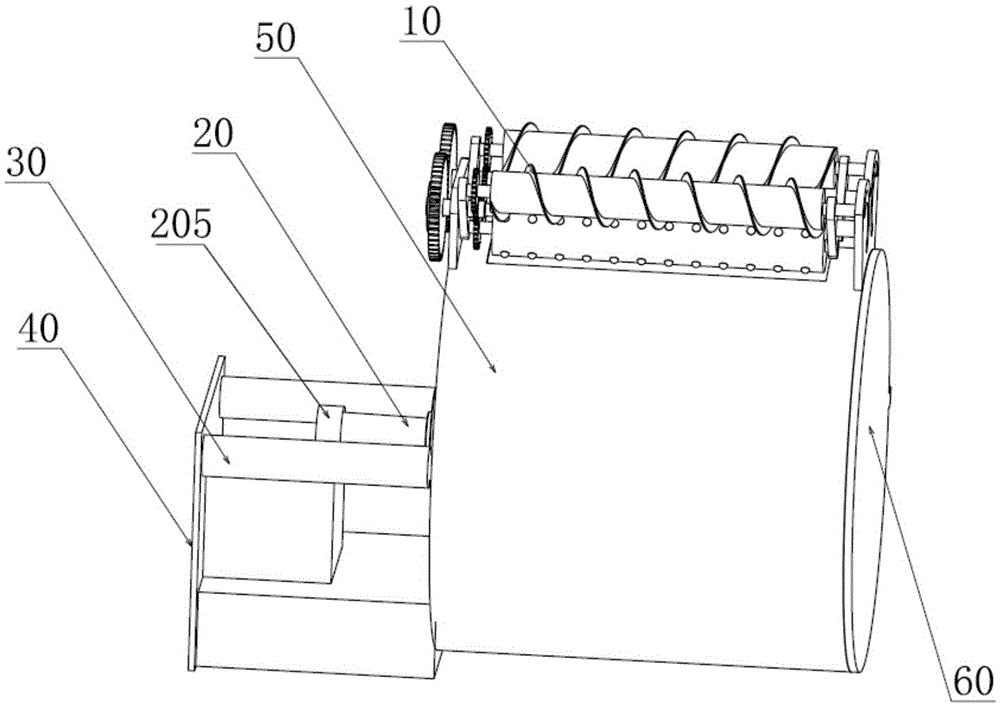

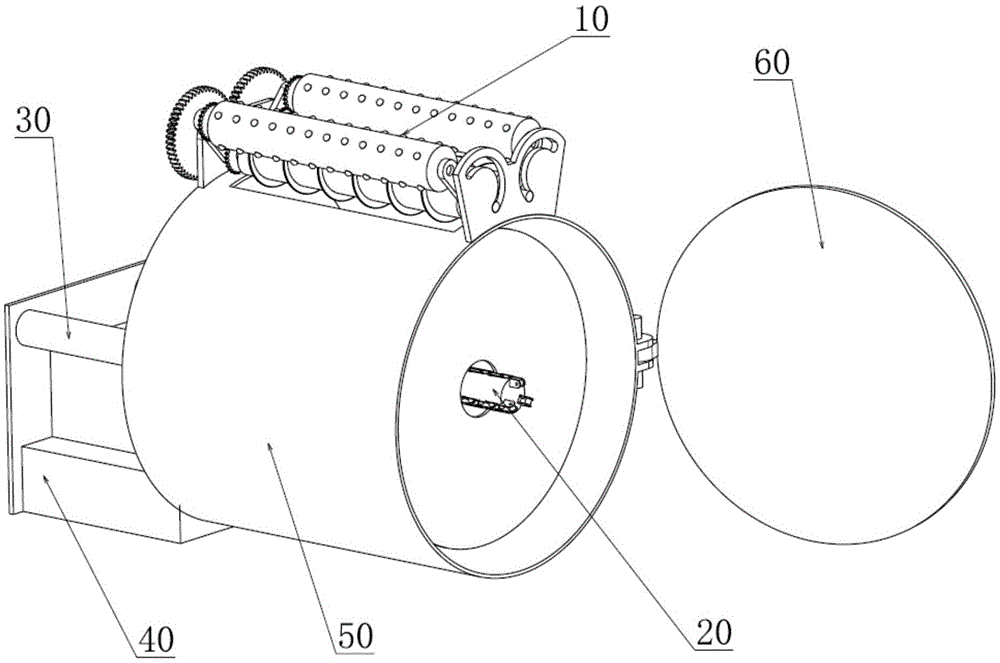

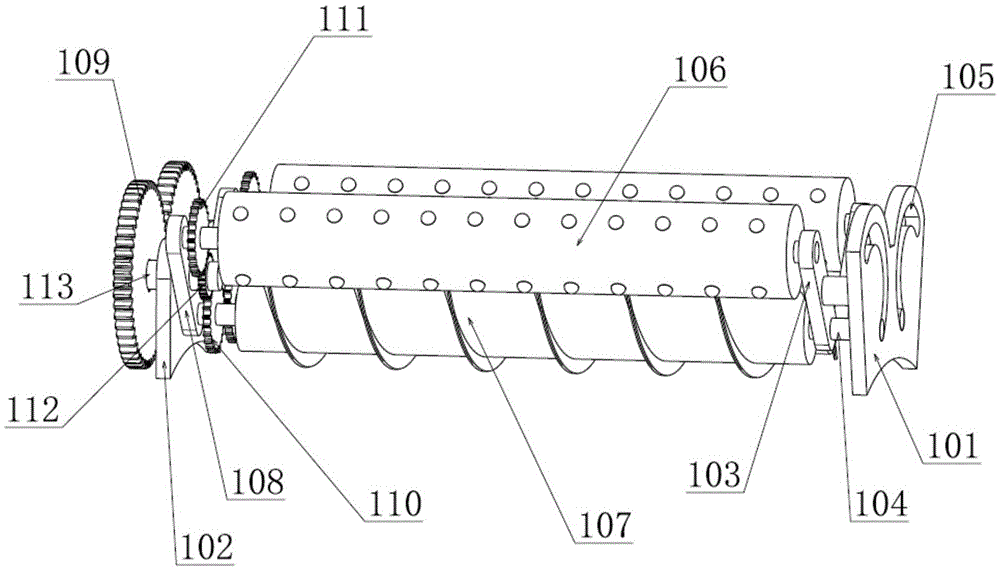

[0020] First refer to figure 1 , which is a three-dimensional schematic diagram of the centrifugal inner-rotating annular bale forming device according to the present invention in the first working position. As shown in the figure, the centrifugal inner-rotating annular bale forming device includes a feeding mechanism 10, a centrifugal stirring mechanism 20, a grass pushing mechanism 30, a frame 40, a forming bin 50 provided with a side bin cover 60, and bearings arranged in pairs Blocks 205 and 206. The forming bin 50 is fixed on the frame 40 and is provided with a feeding port and a discharging port. Grass and / or rice straw can be fed into the forming bin 50 from the outside through the feeding port and the bales formed in the shaping bin 50 can be discharged from the discharge port. exist figure 1 and figure 2In the preferred embodiment shown, the feeding port is arranged on the top of the forming chamber 50 , between the feeding mechanism 10 and the discharge port is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com