Multichannel conversion valve

A multi-way reversing valve, slide valve technology, applied in the direction of fluid pressure actuation device, servo motor assembly, mechanical equipment, etc., can solve the problems of economic loss, high energy consumption, and easy heating of the system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing, the present invention will be further described;

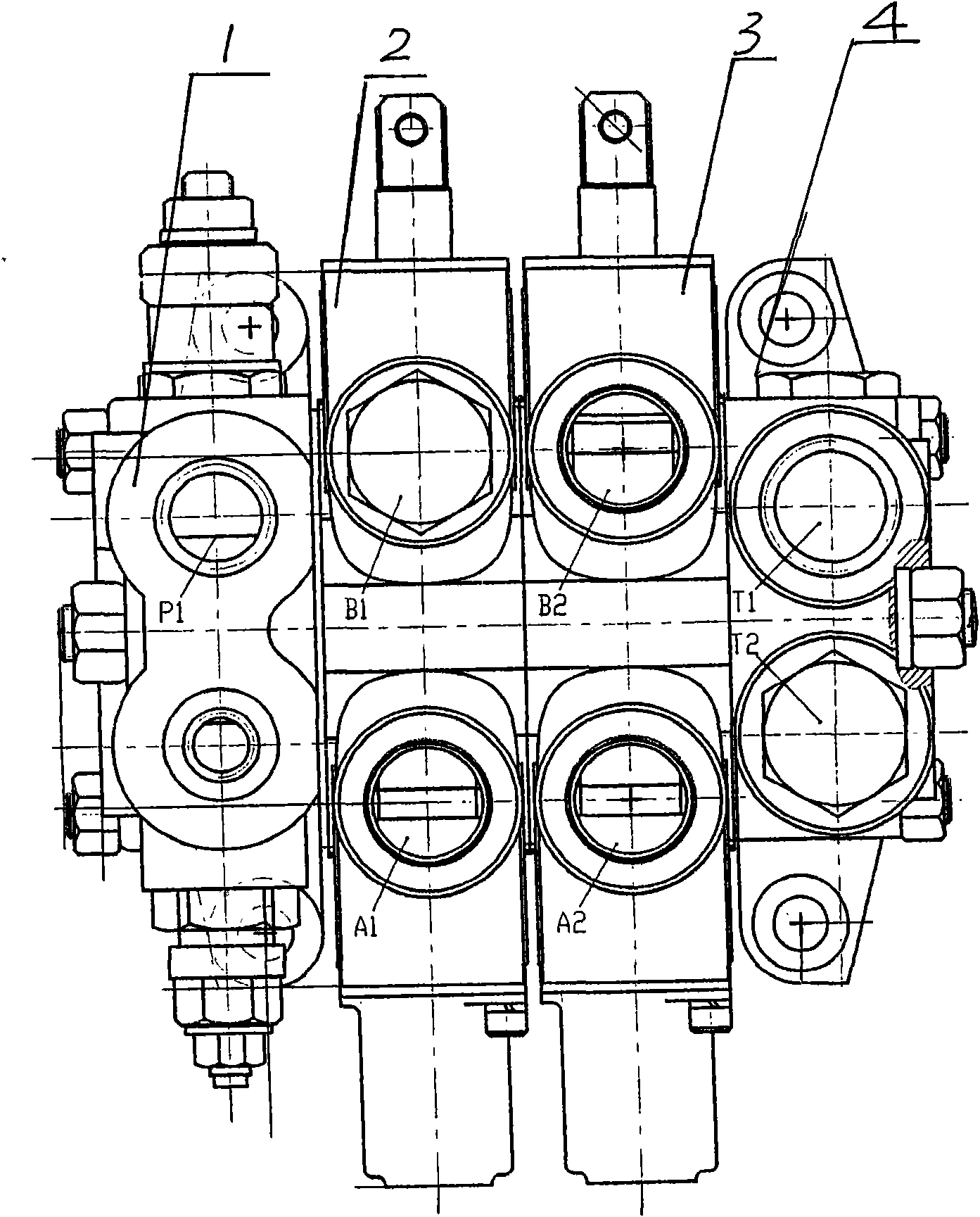

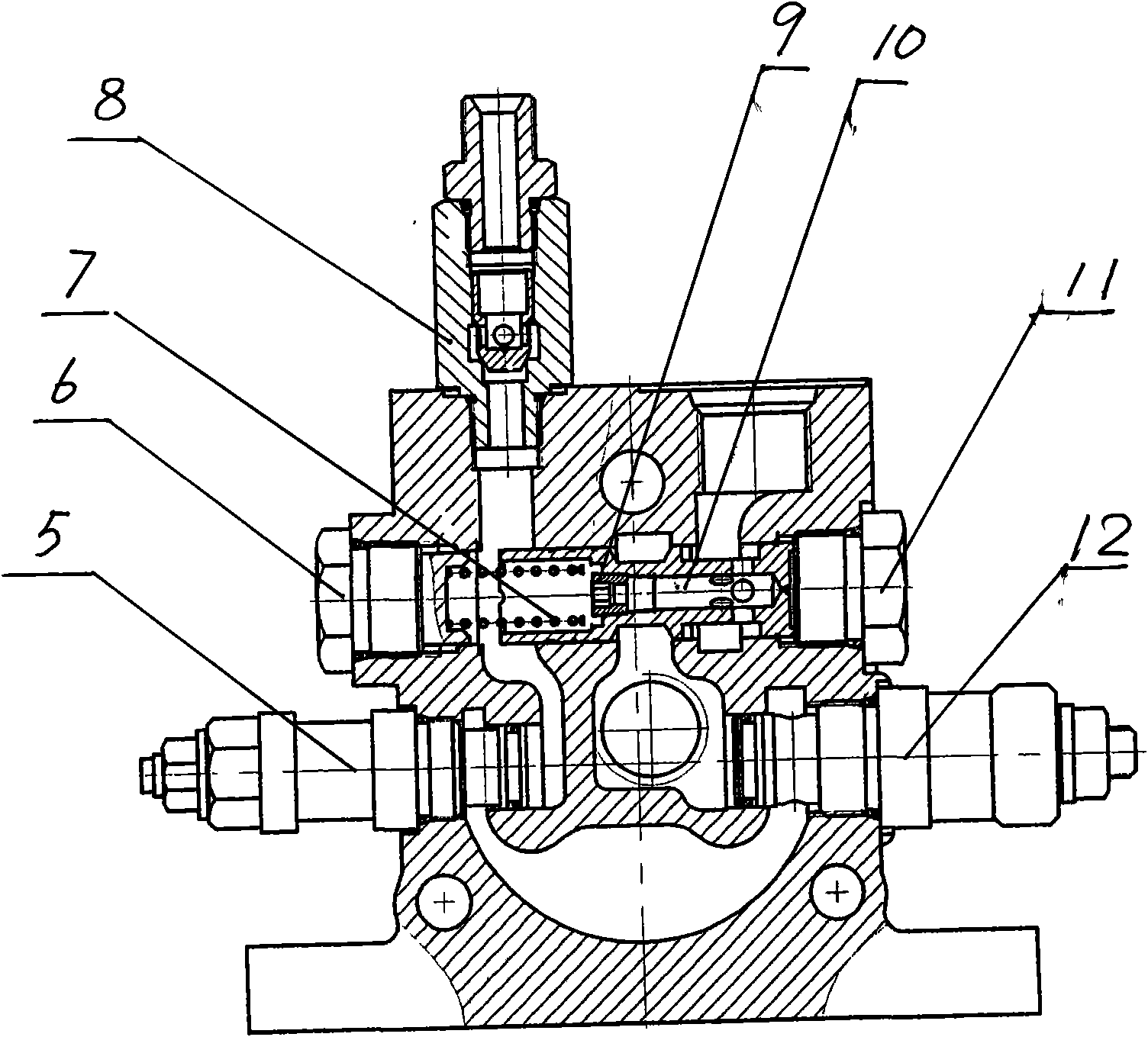

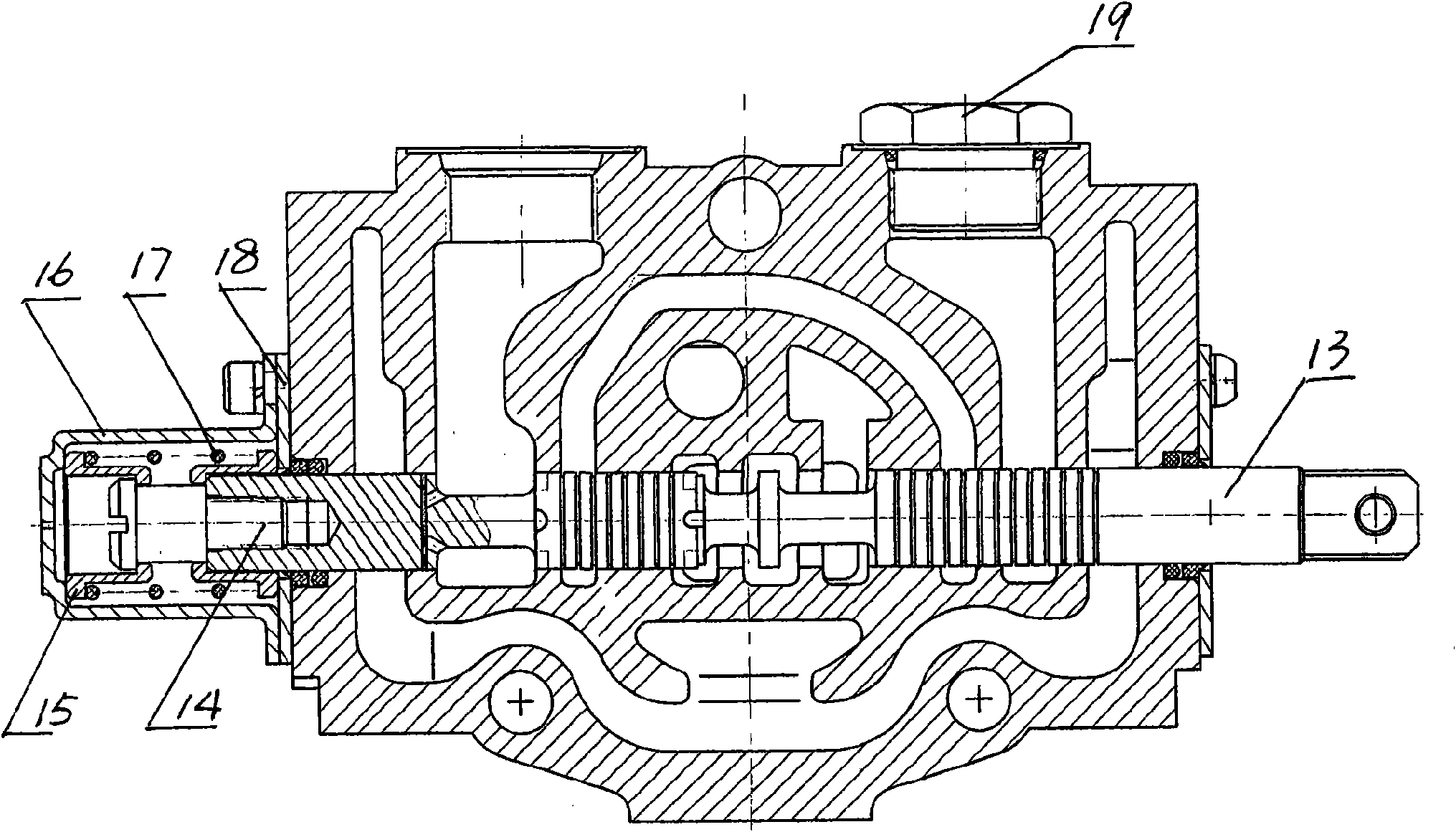

[0010] In the figure, a multi-way reversing valve (CDB2-F20 valve) is composed of an oil inlet valve body part 1, a lifting valve body part 2, an inclined self-locking valve body part 3, and an oil return valve body part 4. It is characterized in that: the left side of the entire valve body is provided with an oil inlet valve body part 1, and the right side of the oil inlet valve body part 1 is provided with a lifting valve body part 2, an inclined self-locking valve body part 3, and an oil return valve body part 4; In the oil inlet valve body part 1, a main overflow valve 12 is provided at the lower end of the right side, a diverter slide valve 9 is provided at the upper left part, and a diverter throttle plug 10 is provided at the right part of the inner cavity of the diverter slide valve 9, and a diverter throttle plug 10 is provided at the left part. The part is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com