Control method for acceleration and deceleration of machinery movable part

A technology of acceleration and deceleration control and drive control, applied in the direction of digital control, electrical program control, etc., can solve the problems of large acceleration, large speed change, and increased speed of the movable part.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

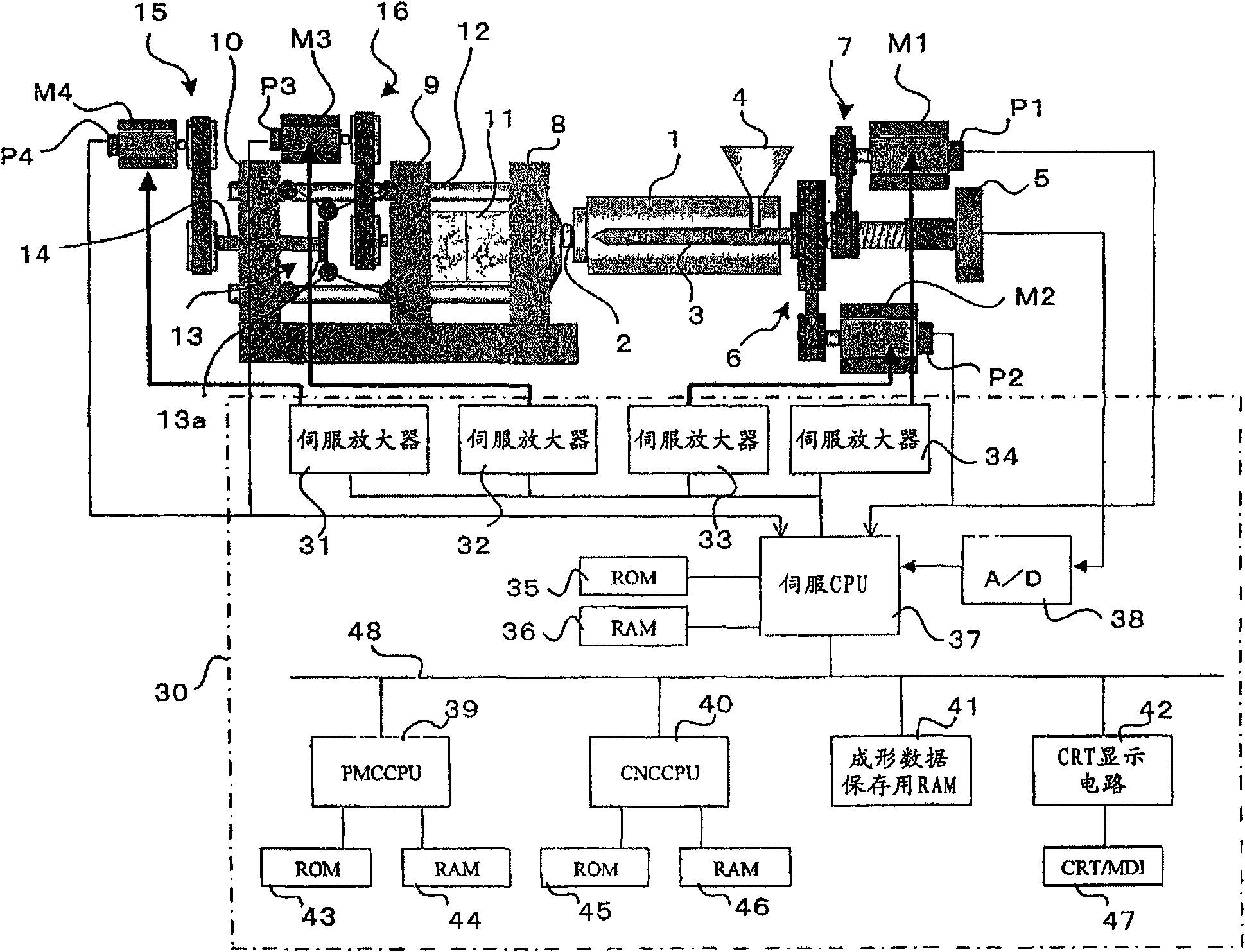

[0027] Next, an example of applying the acceleration / deceleration control method of the mechanical movable part of the present invention to the drive control of the movable platen (movable part) of the electric injection molding machine will be described.

[0028] figure 1 It is a schematic diagram of an example of an electric injection molding machine to which the acceleration / deceleration control method of the present invention is applied.

[0029] A nozzle 2 is mounted on the tip of the injection cylinder 1 . Insert the injection screw 3 into the injection cylinder 1 . The injection screw 3 is provided with a pressure sensor 5 such as a load cell for detecting the resin pressure from the pressure applied to the injection screw 3 . The injection screw 3 is rotated by a servomotor M2 for rotation through a transmission mechanism 6 composed of a pulley, a belt, and the like. In addition, the injection screw 3 is driven by the injection servo motor M1 through the transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com