Method for multi-camera automated high-precision calibration

A multi-camera and calibration method technology, applied in the calibration field, can solve the problems of slow calibration time, and achieve the effect of improving speed and ensuring robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

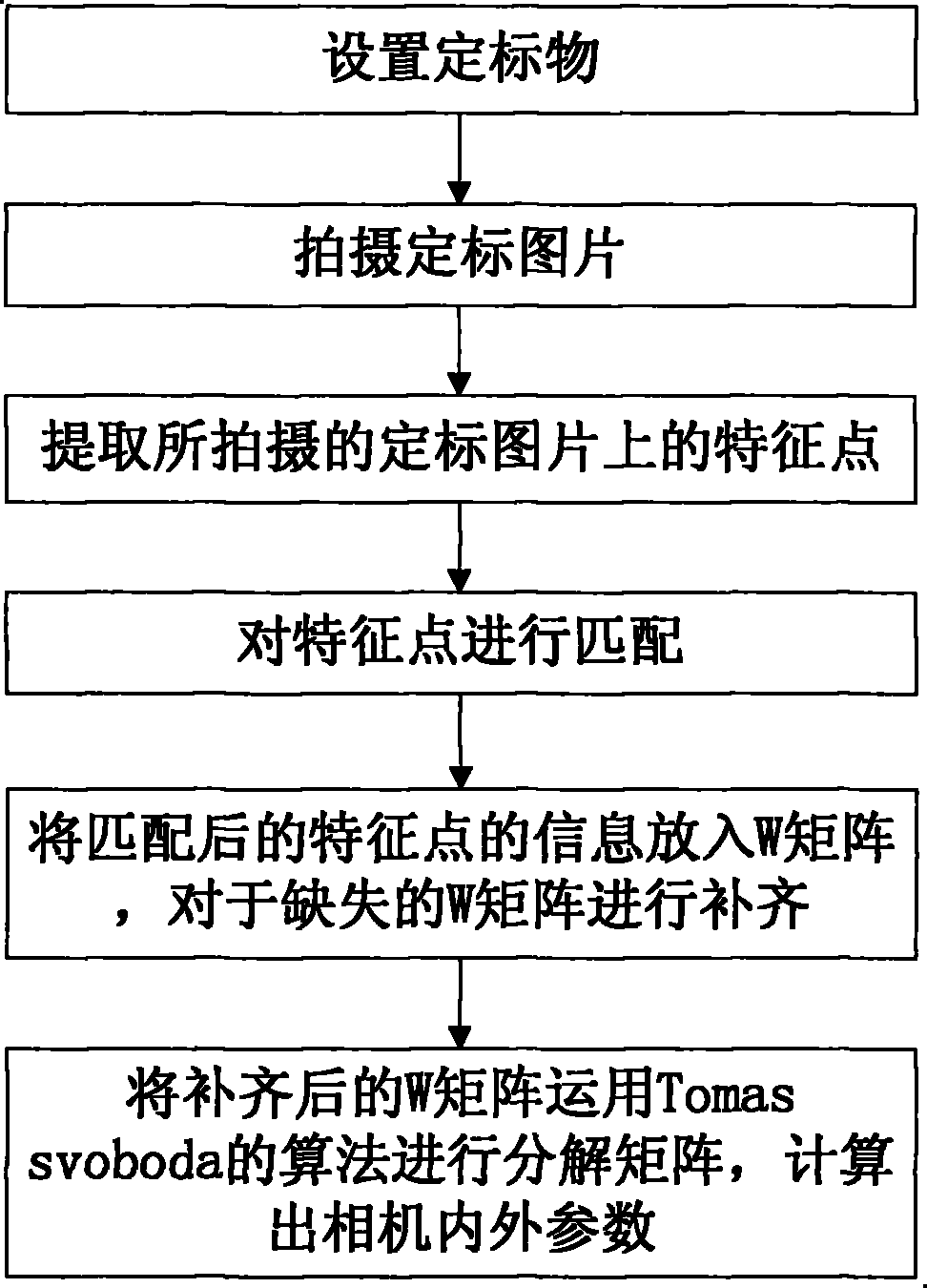

[0054] A kind of multi-camera automatic high-precision calibration method of the present invention, such as figure 2 As shown, the following steps are included: 1. Setting the calibration object; 2. Taking the calibration picture; 3. Extracting the feature points on the taken calibration picture; 4. Matching the feature points; The point information is put into the W matrix, and the missing W matrix is filled; 6. The filled W matrix is decomposed by the algorithm of Tomas svoboda, and the internal and external parameters of the camera are calculated.

[0055] (1) Set the calibration object;

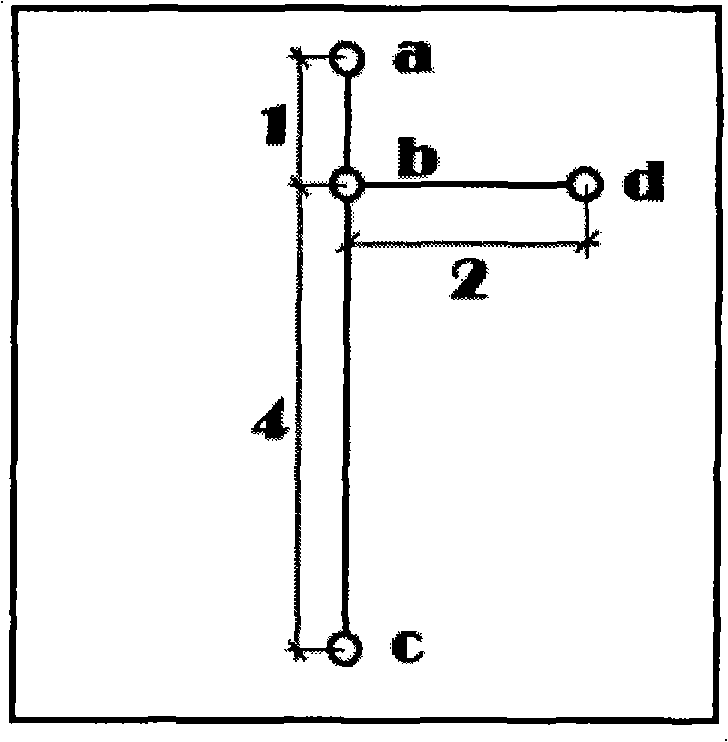

[0056] Such as image 3 As shown, the calibration object consists of four proportional LED light sources a, b, c, and d fixed on a wooden board, where the three LED light sources a, b, and c are collinear, and the three LED light sources a, b, and c The straight line where the light source is located is perpendicular to the straight line where the two LED light sources are located,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com