Method for laying direct current grounding pole

A DC grounding and grounding electrode technology, applied in the direction of connecting contact materials, etc., can solve the problems of increased project construction costs, increased construction costs, and the reduction of the step voltage of the ground electrode. The size of the ground electrode is not obvious, and achieves Simple and easy to implement, increase the floor area, and increase the effect of construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

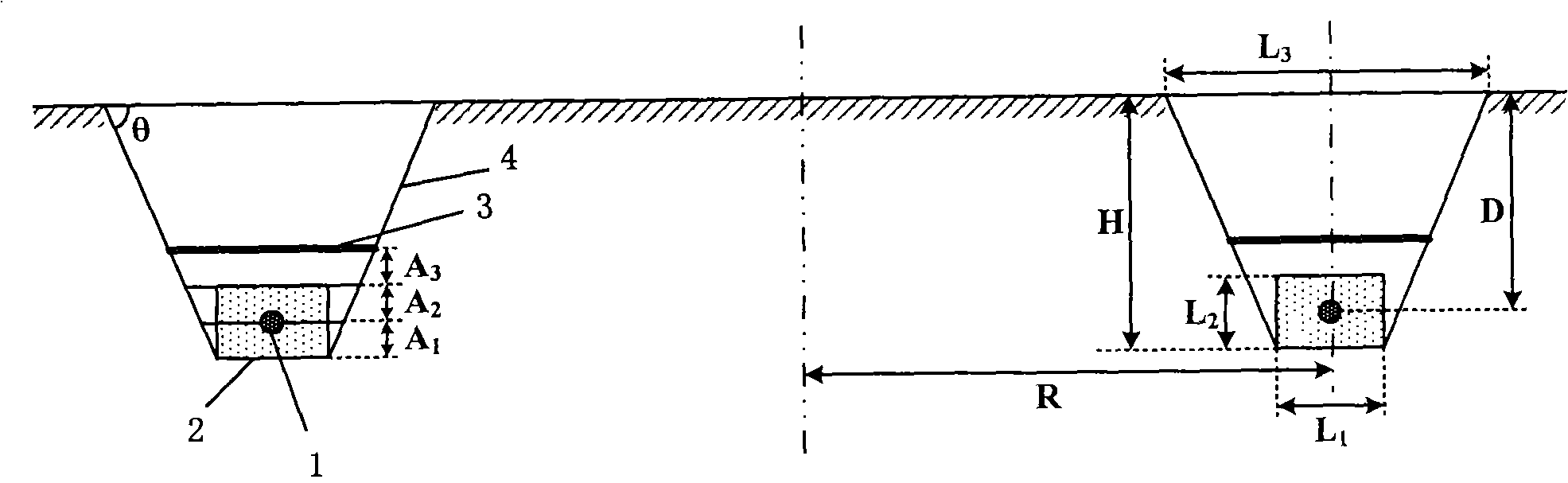

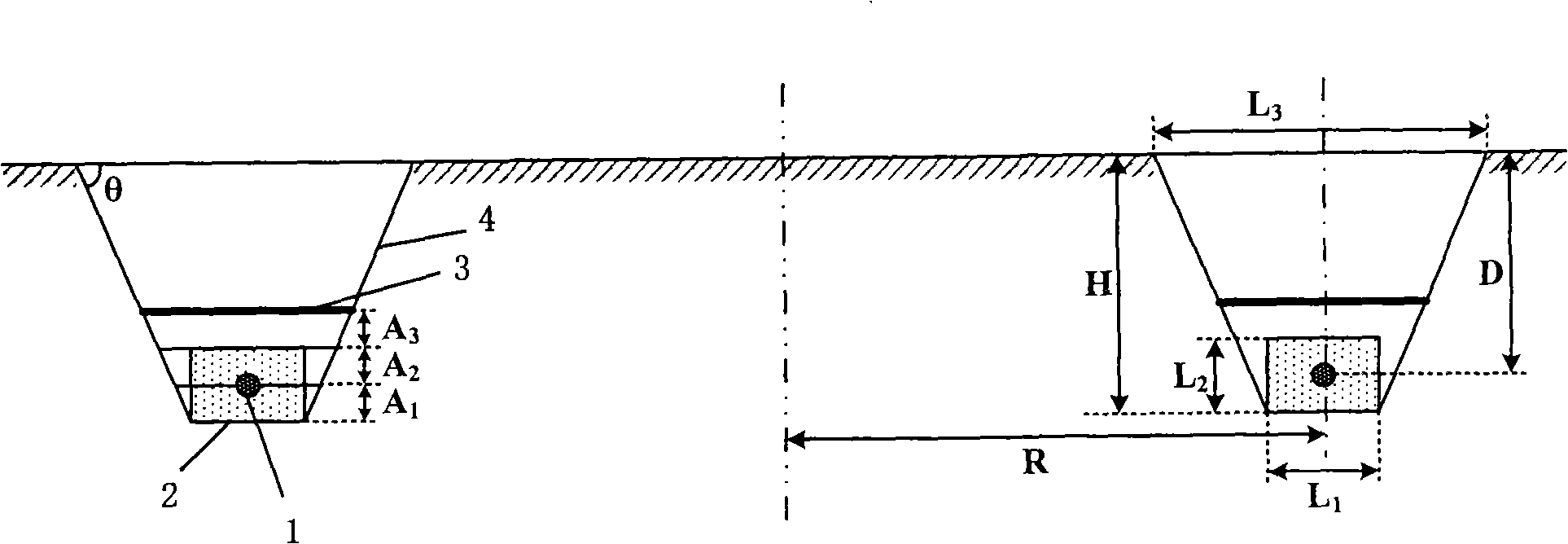

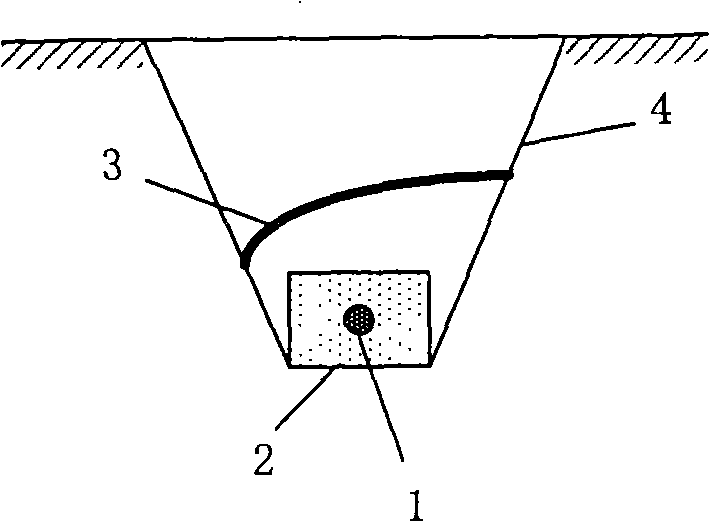

[0029] The embedding method of the DC ground electrode proposed by the present invention, the structure of the embedded circular DC ground electrode is shown in Figure 1, and the embedding process includes the following steps:

[0030] (1) Excavate an annular pit with an isosceles trapezoidal cross section in the soil, the distance between the center line of the trapezoidal section and the center of the circle is equal to the radius R of the circular DC grounding electrode to be buried, and the height H of the trapezoidal section is equal to the The buried depth D of the ground electrode needs to be buried plus the side length L of the rectangular coke section that needs to be wrapped around the ground electrode 2 Half of H=D+1 / 2 L 2 , the length of the bottom side of the trapezoidal section is equal to the length L of the bottom side of the rectangular coke section to be wrapped 1 , the length of the top side of the trapezoidal section is determined by the length of the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com