Grounding device and installation method of substation with cable inlet and outlet

A technology for grounding devices and substations, applied in substation grounding layout, switchgear, electrical components, etc., can solve the problems of reducing grounding resistance, increasing project implementation costs, and unsatisfactory results proved by practice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

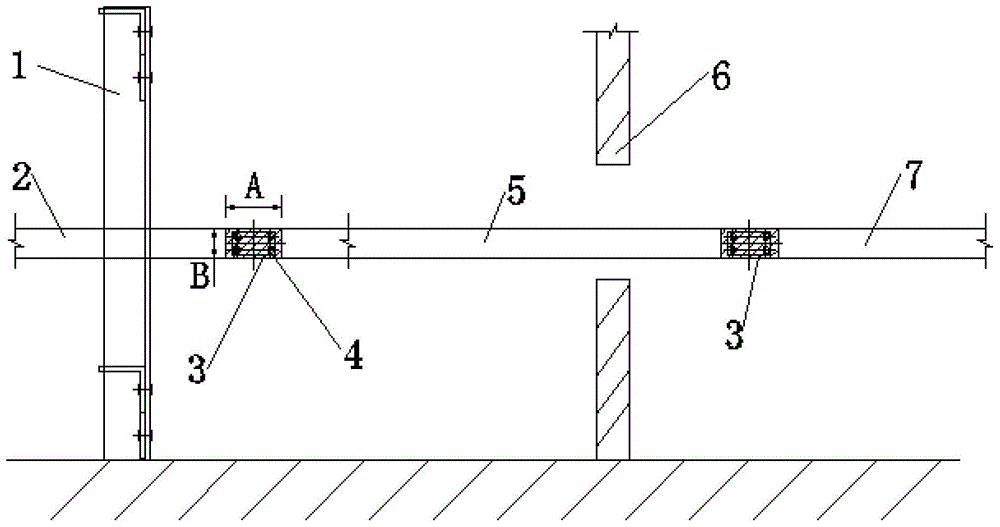

[0019] In this example, refer to figure 1 As shown, a substation grounding device with cable inlet and outlet lines includes a cable trench support grounding flat steel 2 that runs through the cable trench support column 1, and an indoor lead that is locked and connected to the cable trench support grounding flat steel 2 through the first screw 4. The flat steel 5, and the indoor grounding main line 7 locked and connected to the indoor connecting flat steel 5 through the first screw 4, and the grounding flat steel 2 arranged between the cable trench support and the indoor connecting flat steel 5, and the indoor connecting flat Tin layer 3 is applied to the overlapping area between steel 5 indoor grounding trunk lines 7 .

[0020] The distance A of the length A of the tin-plated layer 3 in the overlapping area is greater than or equal to twice the distance B of the width B.

[0021] The first screw 4 is a 12*16 type screw.

[0022] The second screw 9 is an M6*16 screw.

[00...

Embodiment 2

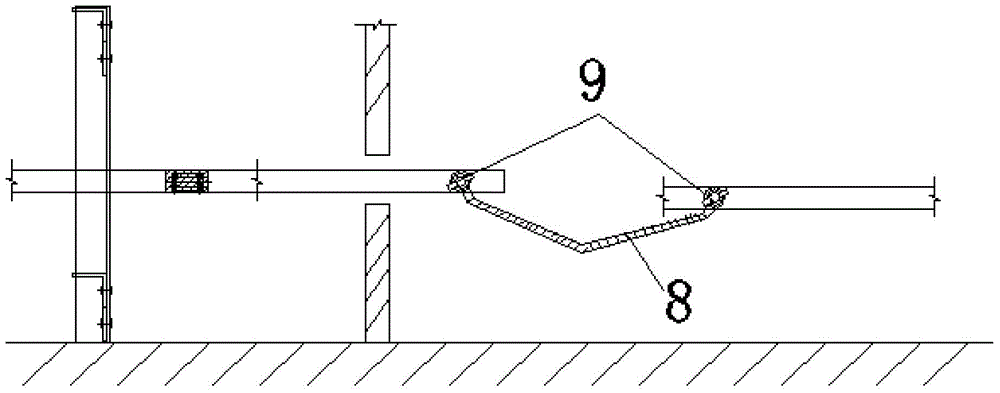

[0025] In this example, refer to figure 2 As shown, the difference from the first embodiment is that the indoor lead flat steel 5 and the indoor grounding trunk line 7 are connected by an indoor copper stranded wire 8 .

[0026] It includes the following steps: 1), cable trench support grounding flat steel 2 penetrates the cable trench support column 1, and indoor connecting flat steel 5 penetrates the outer wall 6 of the substation; 2), then cable trench supporting grounding flat steel 2 and indoor leading flat steel 5. Use 4 first bolts 4 for crimping; 3), then connect the indoor grounding trunk line 7 with the indoor copper stranded wire 8 on one side of the flat steel 5 indoors, and fix it with the second screw; The connection between the bracket grounding flat steel 2 and the indoor lead flat steel 5, and the connection between the indoor lead flat steel 5 and the indoor grounding trunk line 7 are provided with a tin-plated layer 3 in the overlapping area; 5), bolts cann...

Embodiment 3

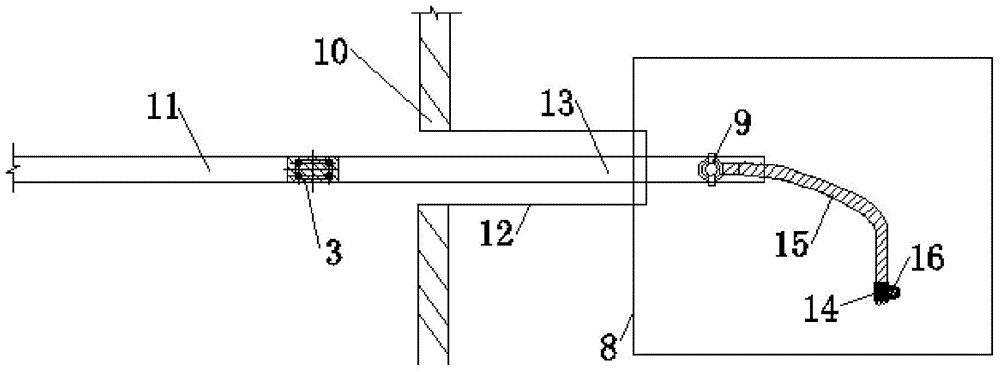

[0028] In this example, refer to image 3 As shown, the difference from Embodiment 1 is that the grounding device of the substation containing the cable inlet and outlet lines includes the grounding trunk line 11 in the piping room, and the grounding flat steel in the piping room that is connected to the grounding trunk line 11 in the piping room through the first screw 4. 13, and the row pipe copper strand 15 fixedly connected with the ground flat steel 13 in the row pipe through the second screw 9, and the exothermic welding joint 14 fixed on the row pipe copper strand 15, and fixed on the exothermic welding joint 14 ground electrode 16 at one end.

[0029] It includes the following steps: 1), the grounding flat steel 13 in the row pipe runs through the outer wall 10 of the substation and the row pipe 12, the grounding trunk line 11 in the row pipe room is locked by the first screw 4 to the grounding flat steel 13 in the row pipe, and the overlapping area is set at the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com