Layered electrically conductive structure and potentiometer comprising such a structure

一种导电材料、薄层的技术,应用在包括多个电阻元件的电阻元件、滑动接触电阻器、抽头的固定电阻器装置等方向,能够解决石墨过热、材料恶化、破裂等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

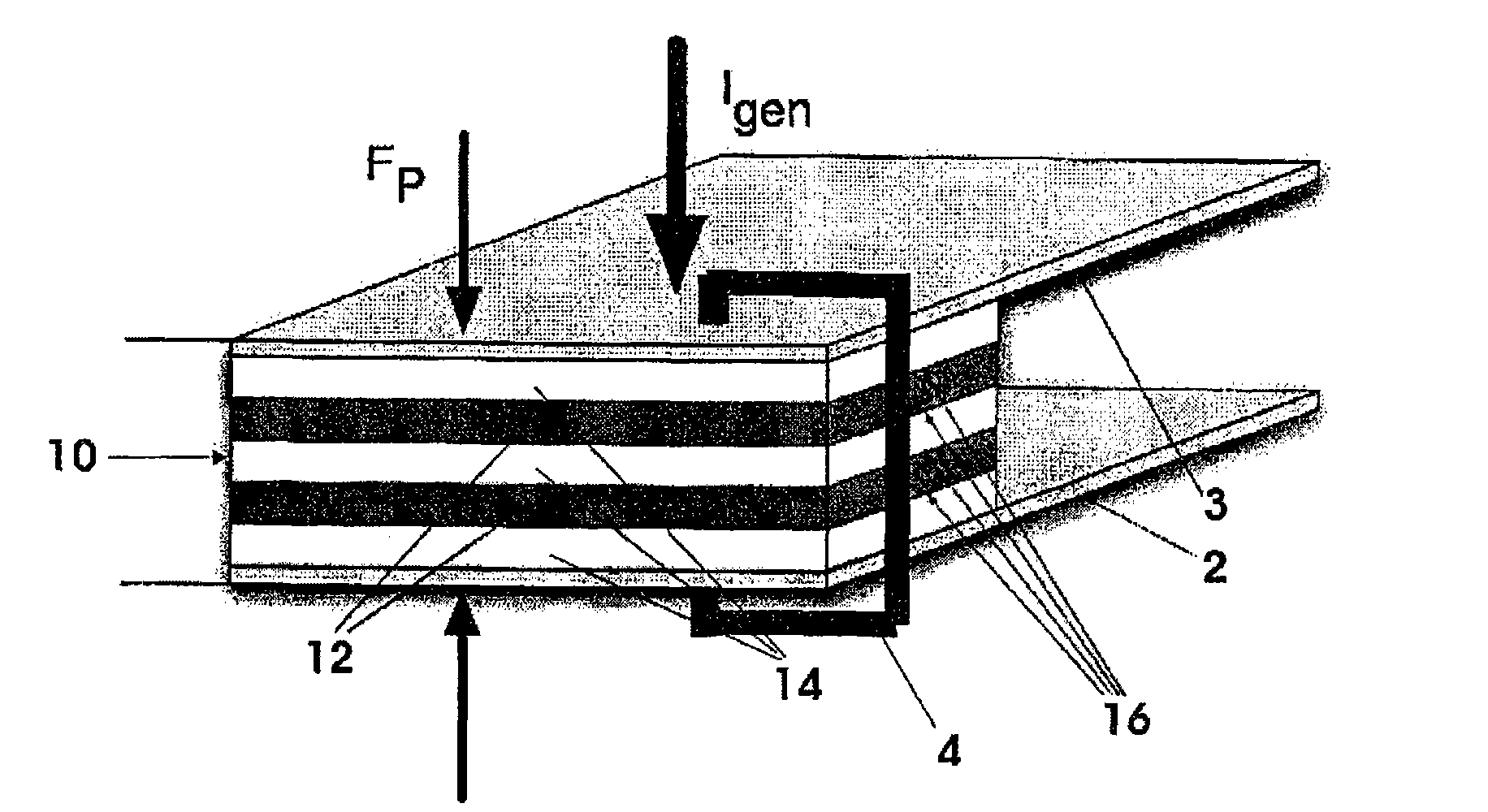

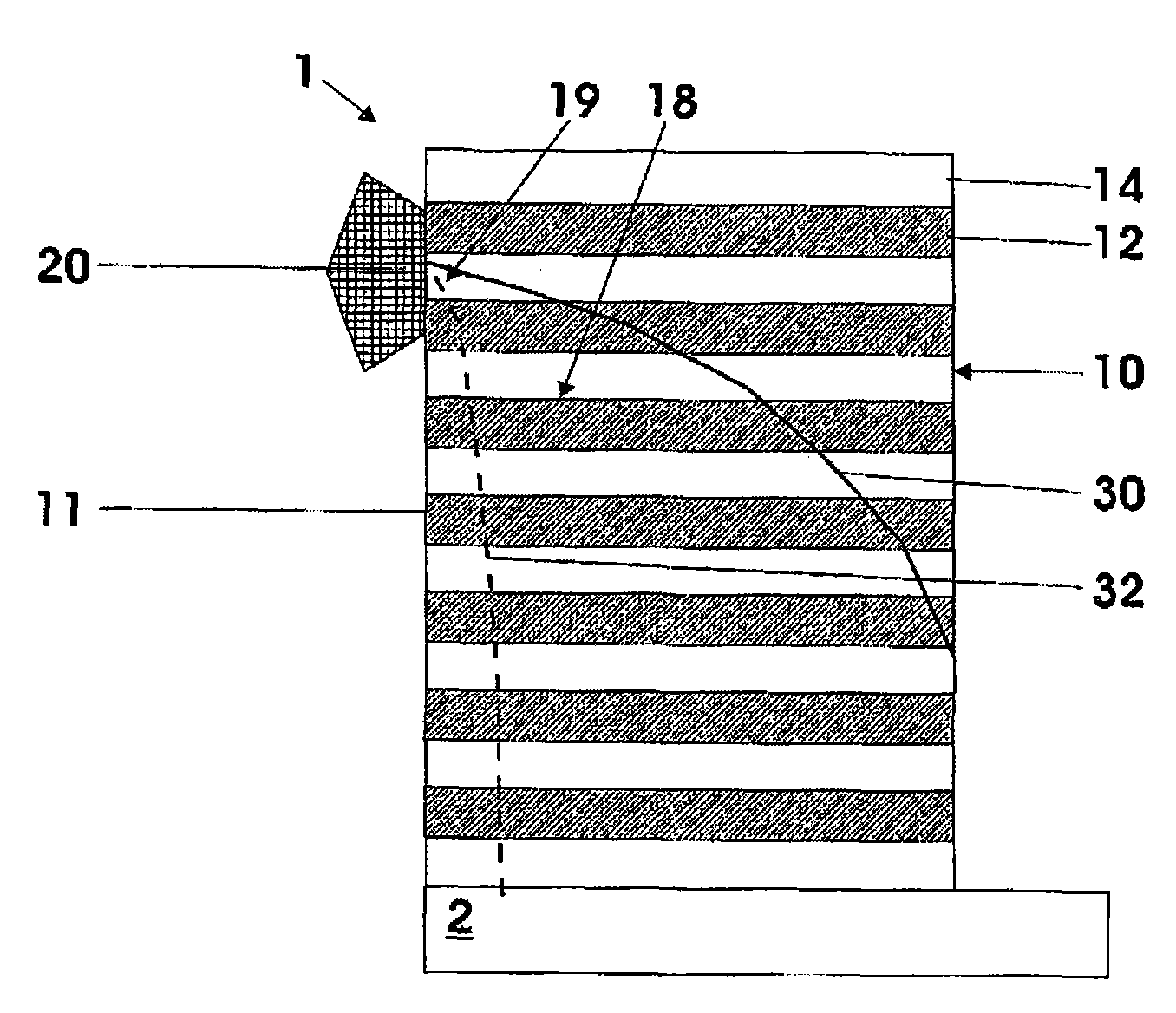

[0012] figure 1 is a perspective view of a conductive resistor 1 according to the invention. The resistor 1 has a bottom plate 2 and a top plate 3 . This resistor 1 further has a conductive laminated body 10 . The conductive stack 10 includes a plurality of conductive metal layers 12 , and a plurality of further conductive layers 14 . exist figure 1 , the layers 12, 14 are arranged on a horizontal plane. This laminate 10 makes it possible to produce highly anisotropic resistors in which the resistance along a direction perpendicular to the layers 12 , 14 is much higher than in the plane of the layers 12 , 14 .

[0013] In the exemplary configuration, the high resistance in the direction perpendicular to the layers 12, 14 may be due to high contact resistance between adjacent layers. A high contact resistance can be caused by a high lumped resistance if the effective contact surface across which the current flows from one layer to another is small; by surface contamination...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com