Method for preparing Pt/C nanometer catalyst and device thereof

A technology of nano-catalyst and preparation device, which is applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalyst, etc., to achieve the effects of convenient operation, large number of units, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

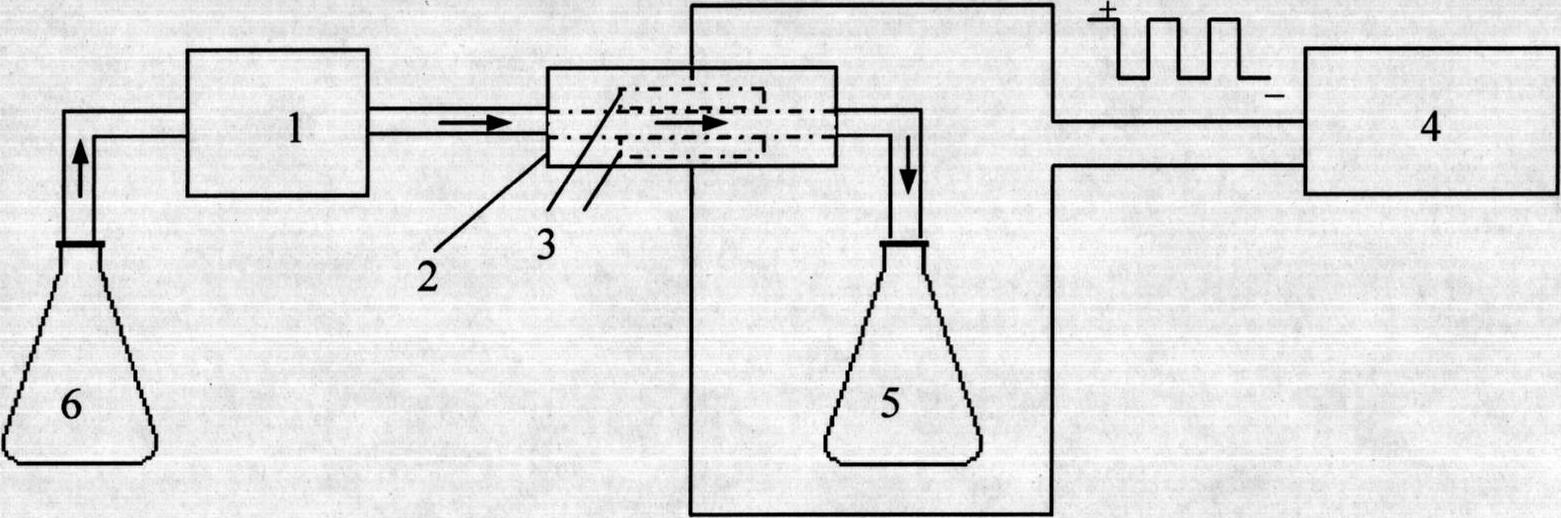

[0026] Embodiment 1: Design the preparation device of carbon-supported platinum nanocatalyst, establish the electrochemical microfluidic system, see figure 1 , the preparation device of the carbon-supported platinum nanocatalyst of the present invention is provided with advection pump 1, reactor 2, two platinum electrodes 3, electrochemical potentiostat 4 and product collection container 5, the input end of advection pump 1 is connected reaction The inlet of the liquid container 6, the output end of the advection pump 1 is connected to the input end of the reactor 2, the output end of the reactor 2 is connected to the product collection container 5, two platinum electrode pieces 3 are embedded in the reactor 2 in parallel, and the advection pump is connected through a pipeline 1. Make the reaction solution flow between the two platinum electrode sheets 3, and the two platinum electrode sheets 3 are respectively connected to the electrochemical potentiostat 4. The two platinum ...

Embodiment 2

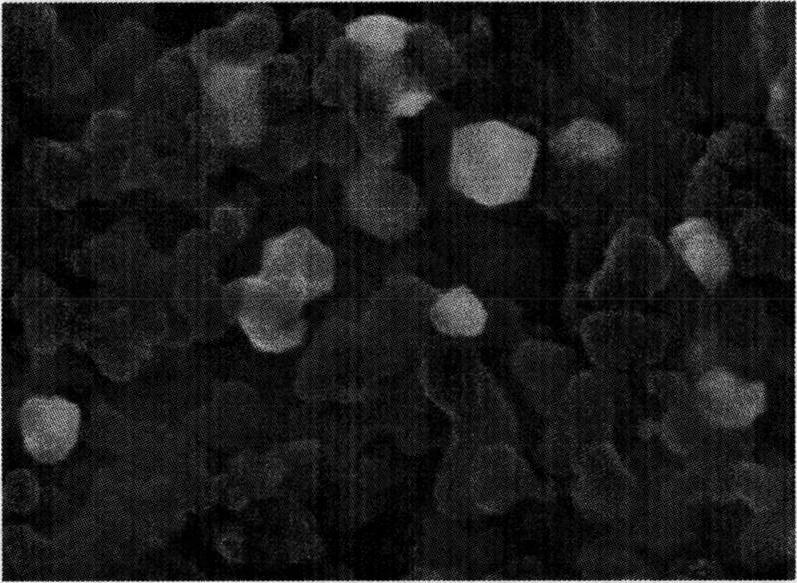

[0027] Example 2: Two platinum electrode sheets are used as the working electrode and the counter electrode respectively, the square wave potential controls the tank pressure, the upper limit potential is 3.0V, the lower limit potential is 3.0V, the square wave frequency is 2Hz, and the carbon black solution flows continuously through the two platinum electrodes Between the sheets, the flow rate was 72 μL / min, the product was received at the outlet of the reactor, and centrifuged to obtain a carbon-supported platinum nanocatalyst with a particle size of about 100 nm. figure 2 is the SEM image of carbon-supported platinum nanocatalysts, by figure 2 It can be seen that the carbon-supported platinum nanocatalyst has a specific crystal shape.

Embodiment 3

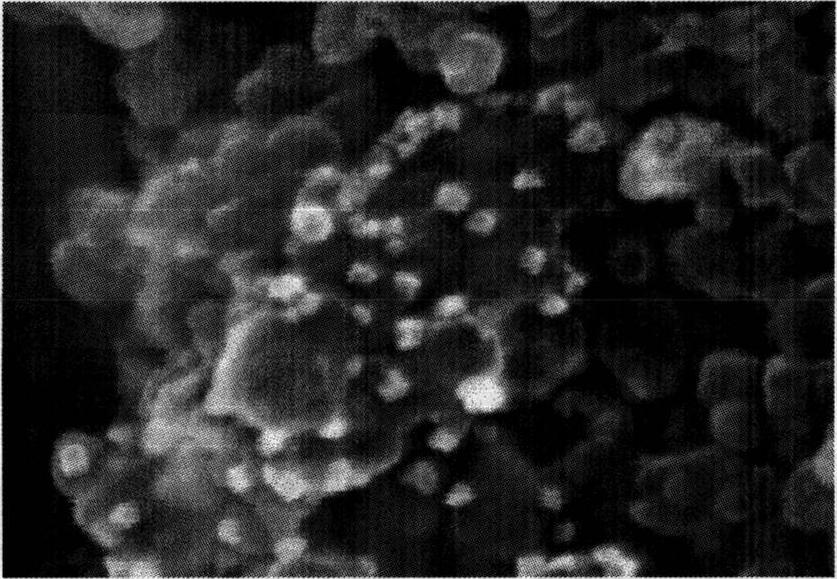

[0028] Embodiment 3: Similar to the process of Example 2, but when preparing carbon-loaded high surface energy platinum nanocatalysts, using saturated calomel as the three-electrode system of the reference electrode, the upper limit potential of the square wave is 1.75V, and the lower limit potential is 0.80V, square wave frequency 10Hz, carbon black solution intermittently flowed between two platinum electrodes at a flow rate of 130 μL / min, and an interval of 60 minutes to prepare a carbon-supported platinum nanocatalyst with a particle size of about 15 nm. image 3 is the SEM image of carbon-supported platinum nanocatalysts, by image 3 It can be seen that the carbon-supported platinum nanocatalyst has a specific crystal shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com