Continuous casting production line of oxygen-free aluminum rod by up-draw process

An oxygen-free aluminum production line technology, which is applied in the continuous casting production line of oxygen-free aluminum rods, can solve the problems of easy oxidation and discoloration of the surface, scrapping, and lower grades of finished products.

Inactive Publication Date: 2011-01-05

贾国荣

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The present invention mainly solves the raw material problem of the continuous extruder. What the continuous extruder originally used was the low-oxygen aluminum rod of continuous casting and rolling. Its first defect is that the oxygen content of the produced product is not high enough. The surface is more likely to be oxidized and discolored if it reaches the international standard; the most important thing is that the surface of the aluminum rod produced by the reverberatory furnace continuous casting and rolling has oil stains on the surface, and it takes a lot of manpower and material resources to clean it and wipe it clean. Dirt makes a large circle of finished products lowered in grade or even scrapped, but now the oxygen-free aluminum rods made by Shangyin are clean oxygen-free aluminum rods that do not contain impurities and dirt, so that they can be used with confidence and reduce The original loss caused by complex processes such as cleaning and peeling has been saved, and a large amount of unnecessary expenses have been saved; the invention has filled the blank in my country's nonferrous metal industry, and also made up for the existing continuous casting and rolling aluminum rod production line. Inadequacies

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

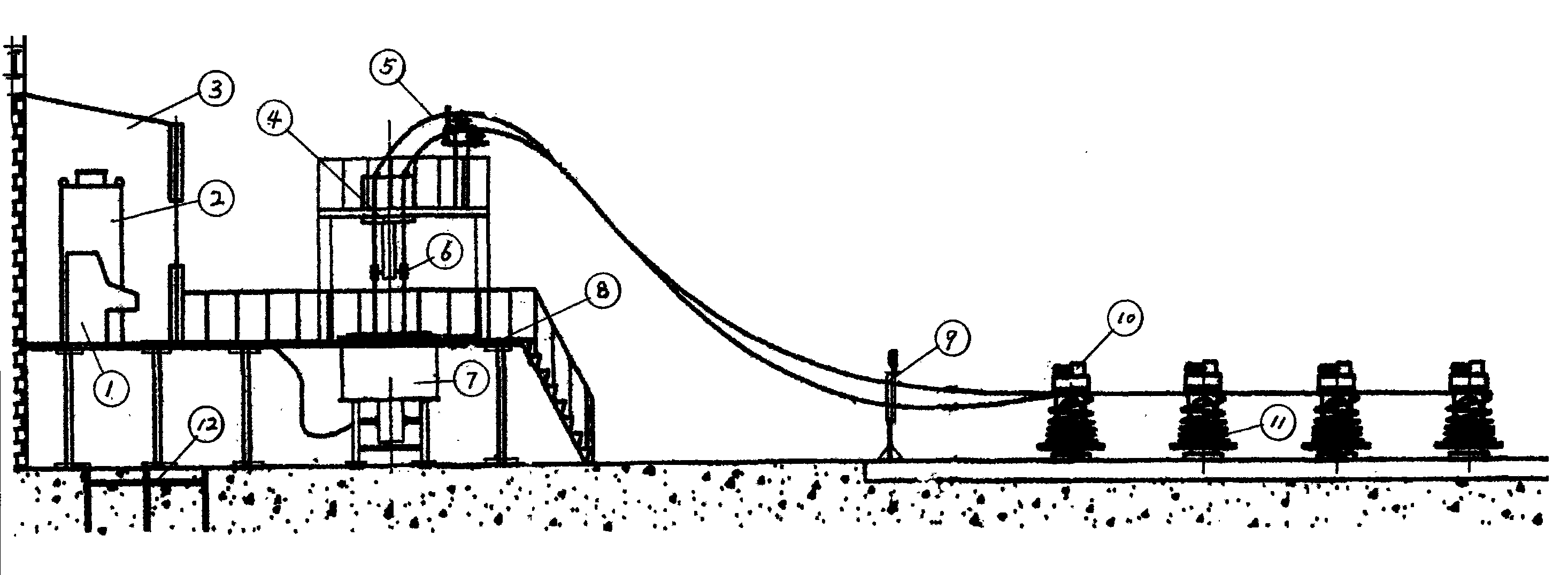

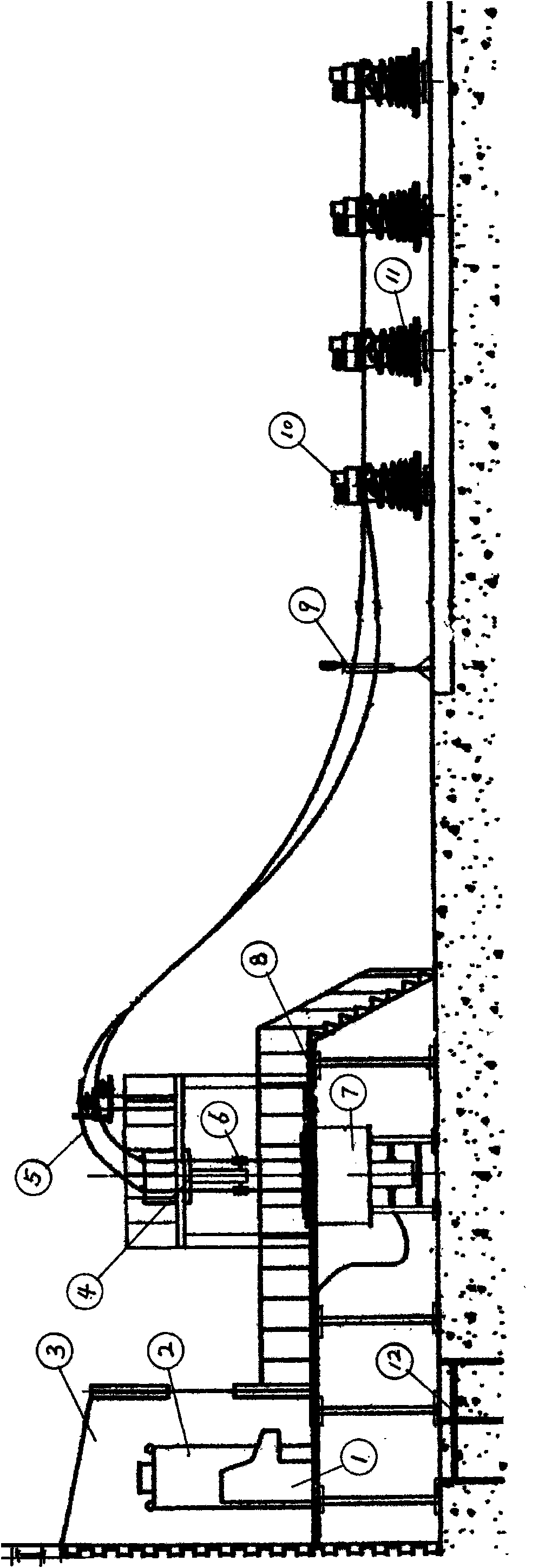

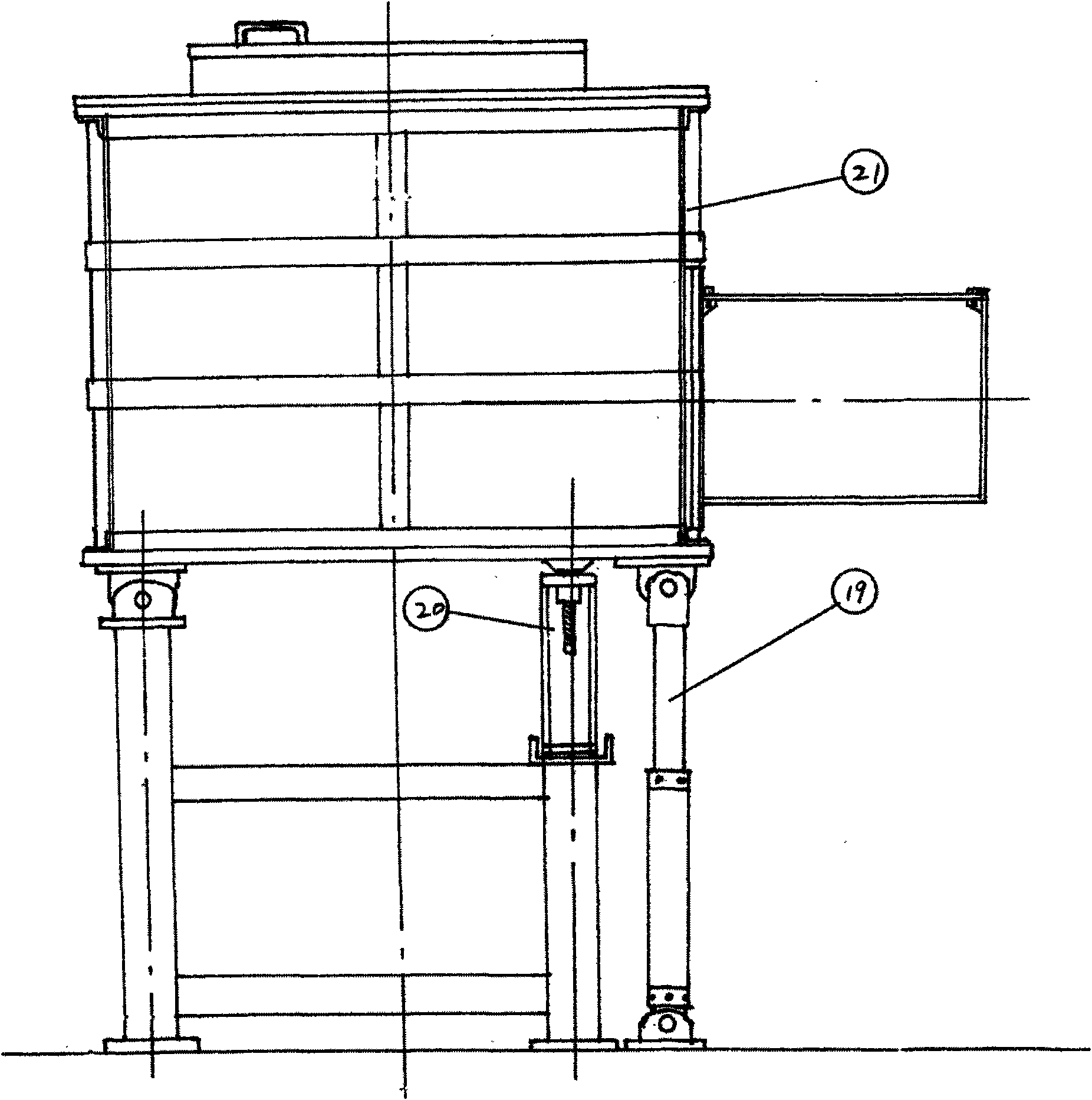

The invention relates to a continuous casting production line of an oxygen-free aluminum rod by an up-draw process, mainly comprising a line frequency induction furnace, a high-density aluminum rod crystallizer, a hydraulic traction system and a low-pressure induction type rod-retracting device; the line frequency induction furnace consists of a melting furnace and a heat holding furnace; the high-density aluminum rod crystallizer is arranged in molten aluminum of the heat holding furnace of the line frequency induction furnace; the hydraulic traction system is positioned above of the high-density aluminum rod crystallizer; an aluminum ingot is melted by the line frequency induction furnace and then preserves heat, is inserted into the molten aluminum by the high-density aluminum rod crystallizer and is cooled and crystallized by internal circulating water; and the oxygen-free aluminum rod is pulled upward intermittently by the hydraulic traction system and is coiled by the low-pressure induction type rod-retracting device. The continuous casting production line avoids the serious waste gas and waste water pollution to the atmosphere caused by the prior art, and avoids the problems, such as scaling, scabbing and napping and the like, of the continuously cast and rolled low-oxygen aluminum rod product when a continuous extruder is used, makes up the defects of the prior art andfills the the industry blank of China.

Description

An oxygen-free aluminum rod continuous casting production line with upward pull method technical field The invention relates to an upward-drawing oxygen-free aluminum rod continuous casting production line, in particular to an upward-drawing continuous casting production line for producing pure high-density oxygen-free aluminum rods with clean surfaces and no dirt. Background technique At present, the aluminum rod production line that is widely used by people is mainly made by spraying and burning heavy oil or gas in a cupola reverberatory furnace to melt aluminum ingots, and then rolling them continuously with a rolling mill. liquid contamination. This equipment is called continuous casting and rolling aluminum rod production line. This kind of continuous casting and rolling equipment has been explicitly eliminated in the United States and European developed countries due to serious pollution, and it is also equipment that has been repeatedly proposed or explicitly prohi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B22D11/14

Inventor 贾国荣

Owner 贾国荣

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com