Method for detecting compacting quality of roadbed

A detection method and compaction quality technology, applied in the direction of material inspection products, etc., can solve the problems of inability to quickly and accurately evaluate the project quality, high detection cost, and affect the construction progress, so as to improve the efficiency of detection work, ensure the quality of the project, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Further description will be given below in conjunction with the examples.

[0035] The method for detecting the quality of subgrade compaction comprises the following steps:

[0036] step 1

[0037] The earthwork subgrade shall be filled and compacted in layers according to the designed section, and the compacted thickness of the layers shall not exceed 20cm;

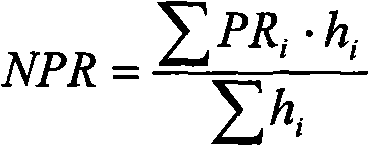

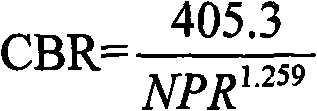

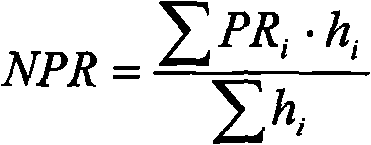

[0038] After the compaction of each layer of filling is completed, random inspection shall be carried out, and the inspection frequency shall be every 2000m 2 Inspect 8 points, and measure the penetration rate PR (unit: mm / hammering time, usually take the value of one hammering) at the inspection point by standard penetration with Dynamic Cone Penetrometer (DCP).

[0039] The detection method of penetration rate PR is:

[0040] ①Select the point to be tested, and move the DCP to the test site for testing;

[0041] ②Put the sliding rod vertically on the ground, and put the ruler parallel to the sliding rod;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com