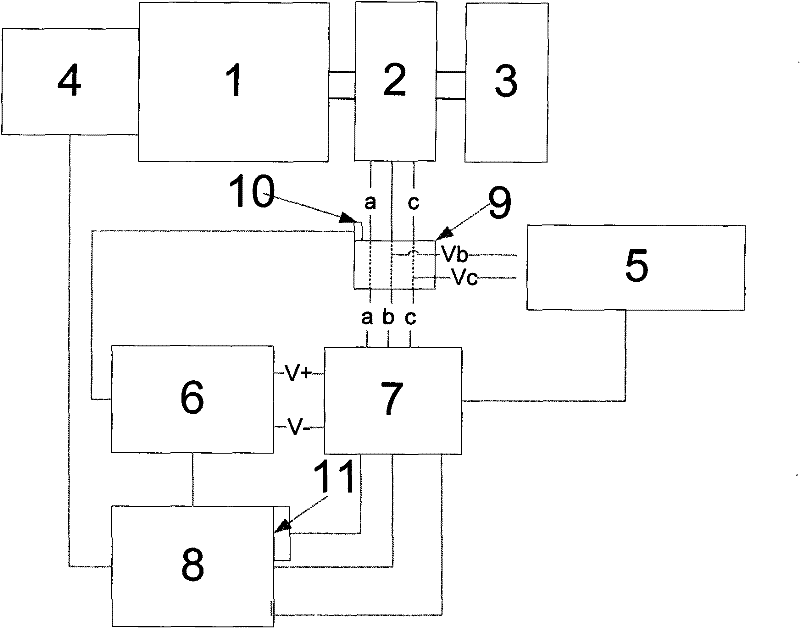

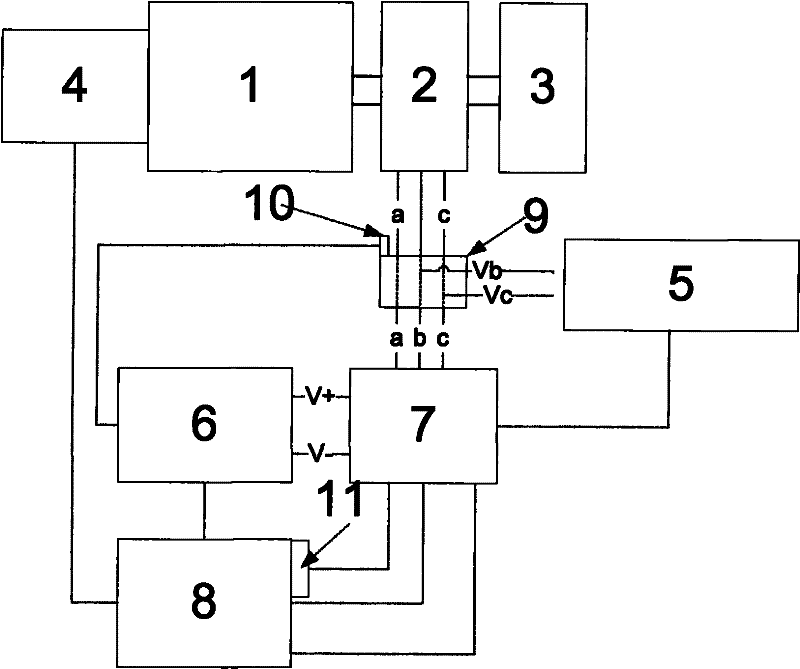

Testing system of hybrid power motor and testing method thereof

A technology of hybrid power and testing methods, which is applied in the direction of motor generator testing, measuring electricity, measuring devices, etc., can solve the problems of motor not running, waste of manpower and material resources, and motor cannot provide auxiliary torque, so as to save procedures and facilitate maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

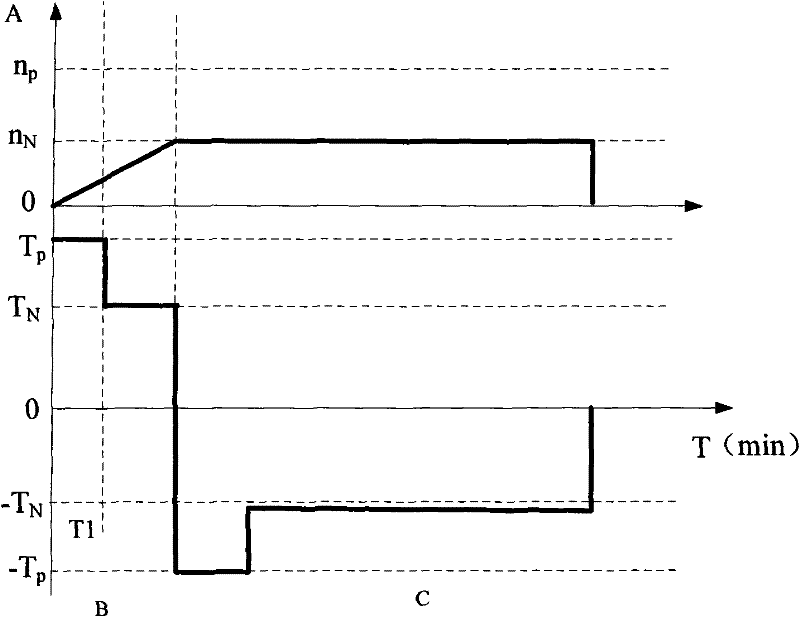

Method used

Image

Examples

Embodiment Construction

[0065] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

[0066] First, calibrate the position sensor of the motor. At this time, the assembled power assembly is placed on the trolley for the hot test of the engine. The two sets of cooling systems for the engine and the motor are assembled. At this time, use the calibration controller of the motor to start the engine, and the engine starts. Finally, the ISG motor exits to idle mode, that is, idle mode. When the engine speed stabilizes at about 800rpm, the MCU (motor controller) enters the calibration mode Alignment mode. At this time, the alignment calibration of the position sensor is realized through the zero point detection device and the algorithm in the MCU. , and output the calibration value to the PC through CAN. Before the hybrid controller HCU is installed in the vehicle, the calibration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com