FFS type TFT-LCD array substrate structure and manufacture method thereof

A technology of array substrate structure and manufacturing method, applied in semiconductor/solid-state device manufacturing, optics, instruments, etc., can solve problems such as uneven pixel electrode, liquid crystal orientation, confusion, etc., to improve picture quality, eliminate step end difference, and improve freedom degree of effect

Active Publication Date: 2010-12-01

BOE TECH GRP CO LTD +1

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to provide an FFS type TFT-LCD array substrate structure and its manufacturing method, which can effectively solve the technical defects of the array substrate structure in the prior art, such as disordered liquid crystal orientation caused by uneven pixel electrodes.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

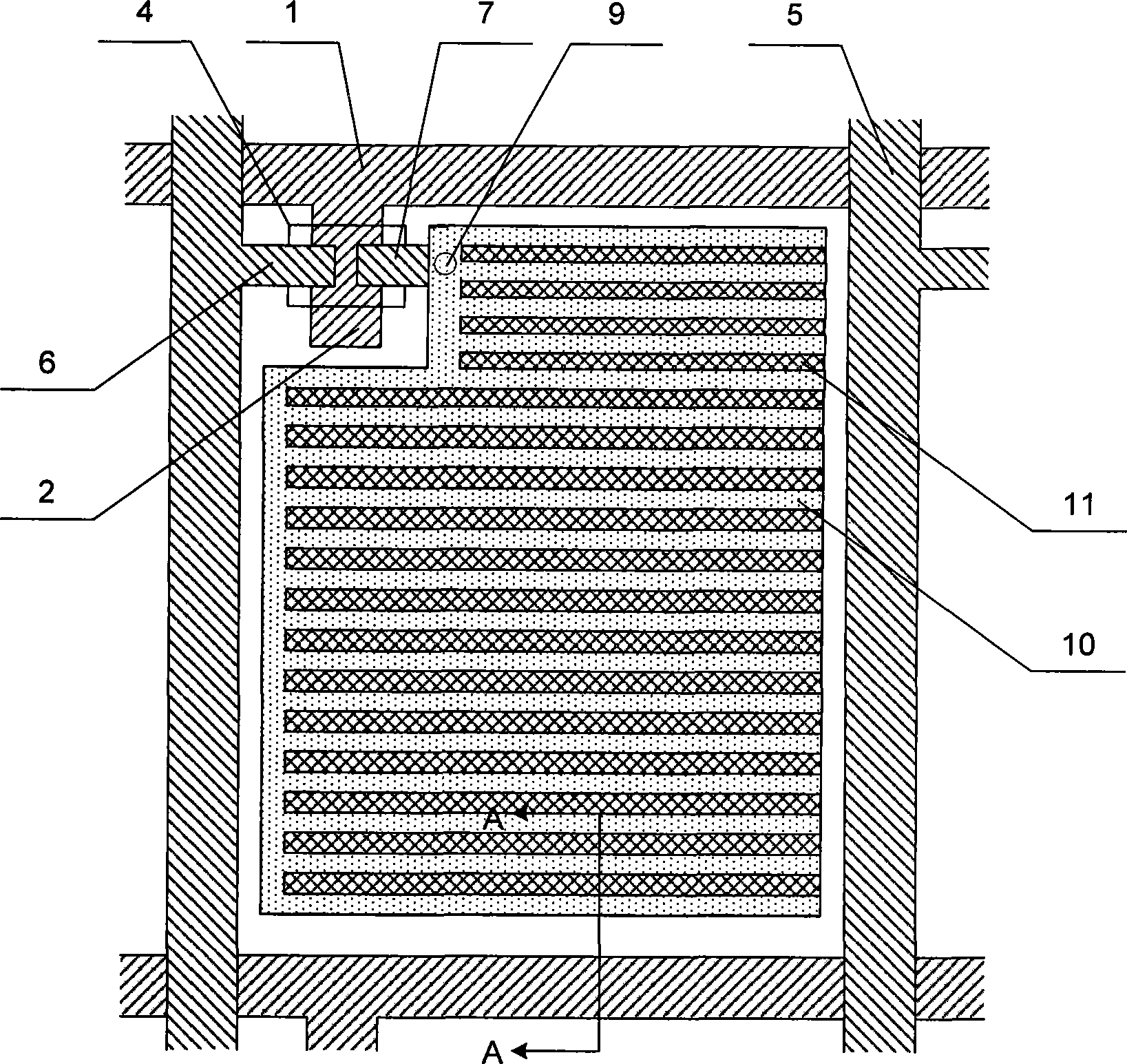

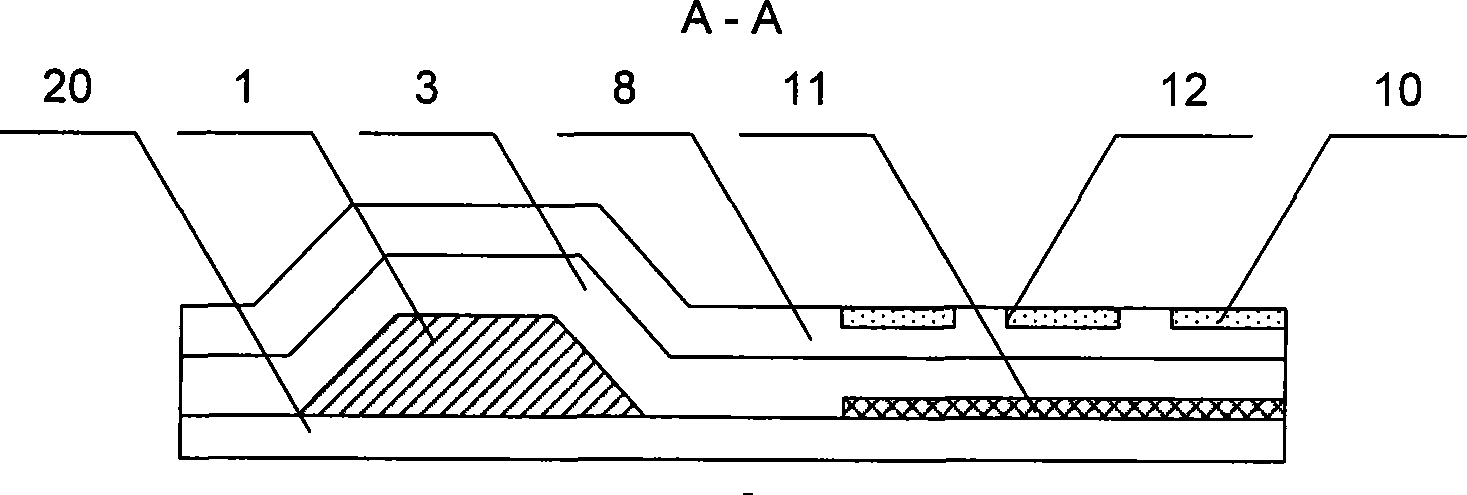

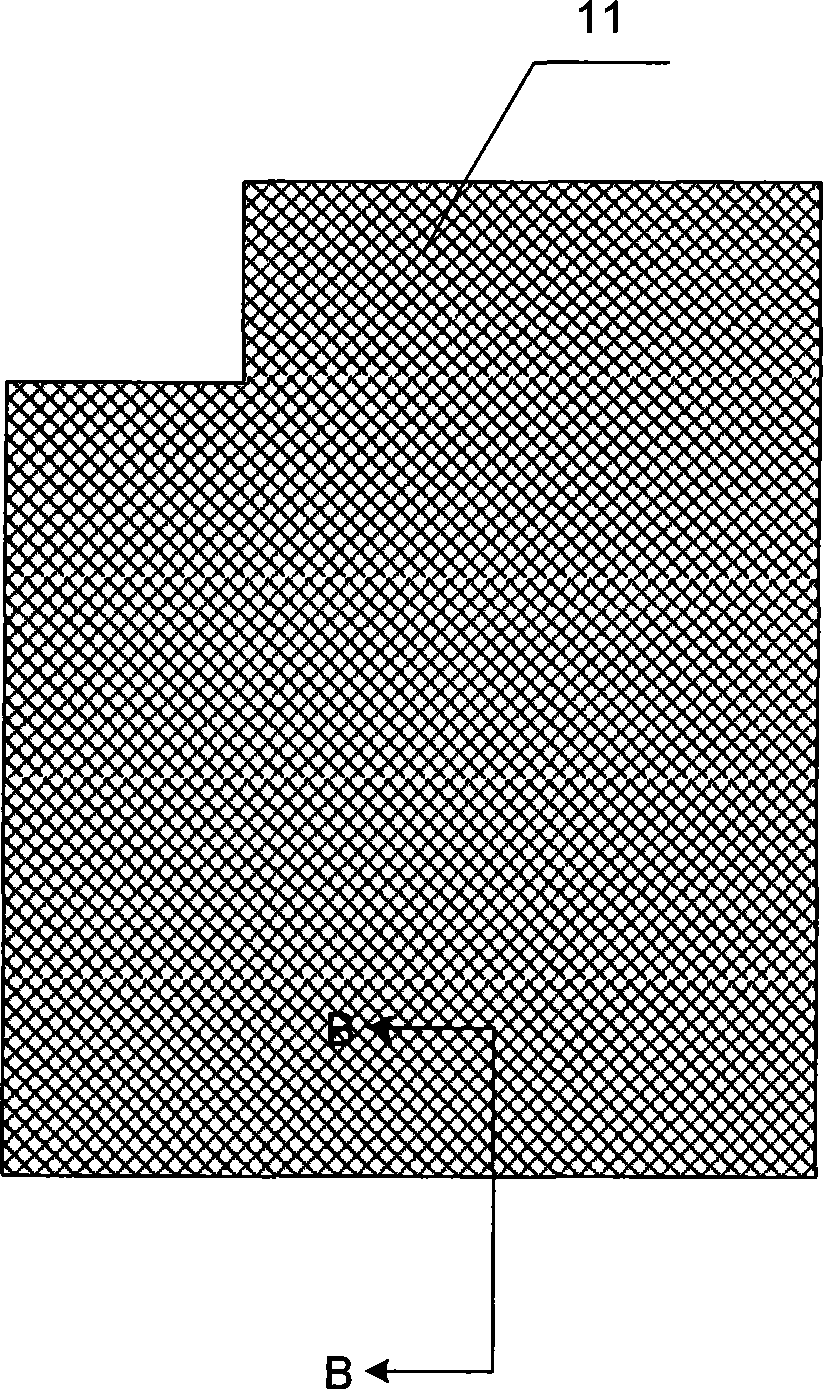

The invention relates to an FFS type TFT-LCD array substrate structure and a manufacture method thereof. The array substrate structure comprises a substrate, a public electrode, a grid line, a grid electrode, a grid insulating layer, an active layer, a data wire, a source electrode, a drain electrode and a passivation layer, wherein the public electrode, the grid line, the grid electrode, the gridinsulating layer, the data wire, the source electrode, the drain electrode and the passivation layer are formed on the substrate; and the active layer is formed on the grid insulating layer and positioned on the grid electrode. Passivation layer grooves which are in strip shapes and are sequentially arranged are formed in a pixel area; a passivation layer through hole is formed at the position ofthe drain electrode; pixel electrodes are formed on the passivation layer, positioned in the passivation layer grooves and connected with the drain electrode through the passivation layer through hole. The invention farthest eliminates the terminal temperature difference (TTD) of the pixel electrodes in the pixel area, and flat surfaces of the pixel electrodes ensure that the subsequent frictionorientation process of orientation films can obtain uniform orientation angles, thereby the quality of pictures is improved, and the degree of freedom for designing the pixel electrodes is greatly improved.

Description

FFS type TFT-LCD array substrate structure and manufacturing method thereof technical field The invention relates to a thin film transistor liquid crystal display and a manufacturing method thereof, in particular to an FFS type TFT-LCD array substrate structure and a manufacturing method thereof. Background technique In recent years, with the popularization of digital TV, the traditional CRT display has been gradually replaced by a new generation of display devices, including PDP, OLED, LCD, etc., among which Thin Film Transistor Liquid Crystal Display (TFT-LCD) has a small size, Features such as low power consumption, no radiation, and high display resolution have begun to be widely popularized and become mainstream products. Fringe Field Switching (FFS for short) is one of the technologies that have emerged in recent years that can improve the image quality of LCDs, and can simultaneously meet the requirements of high penetration and large viewing angles. The so-called ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G02F1/1362H01L27/12H01L23/522H01L21/84H01L21/768

Inventor 陈旭闵泰烨林承武谢振宇

Owner BOE TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com