Wireless detecting system used for mechanical processing

A wireless detection and machining technology, applied in radio transmission systems, general control systems, transmission systems, etc., can solve the problems of high cost, large site range, cumbersome wiring, etc., and achieve small space constraints, convenient layout, and small size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be further elaborated below in conjunction with the accompanying drawings.

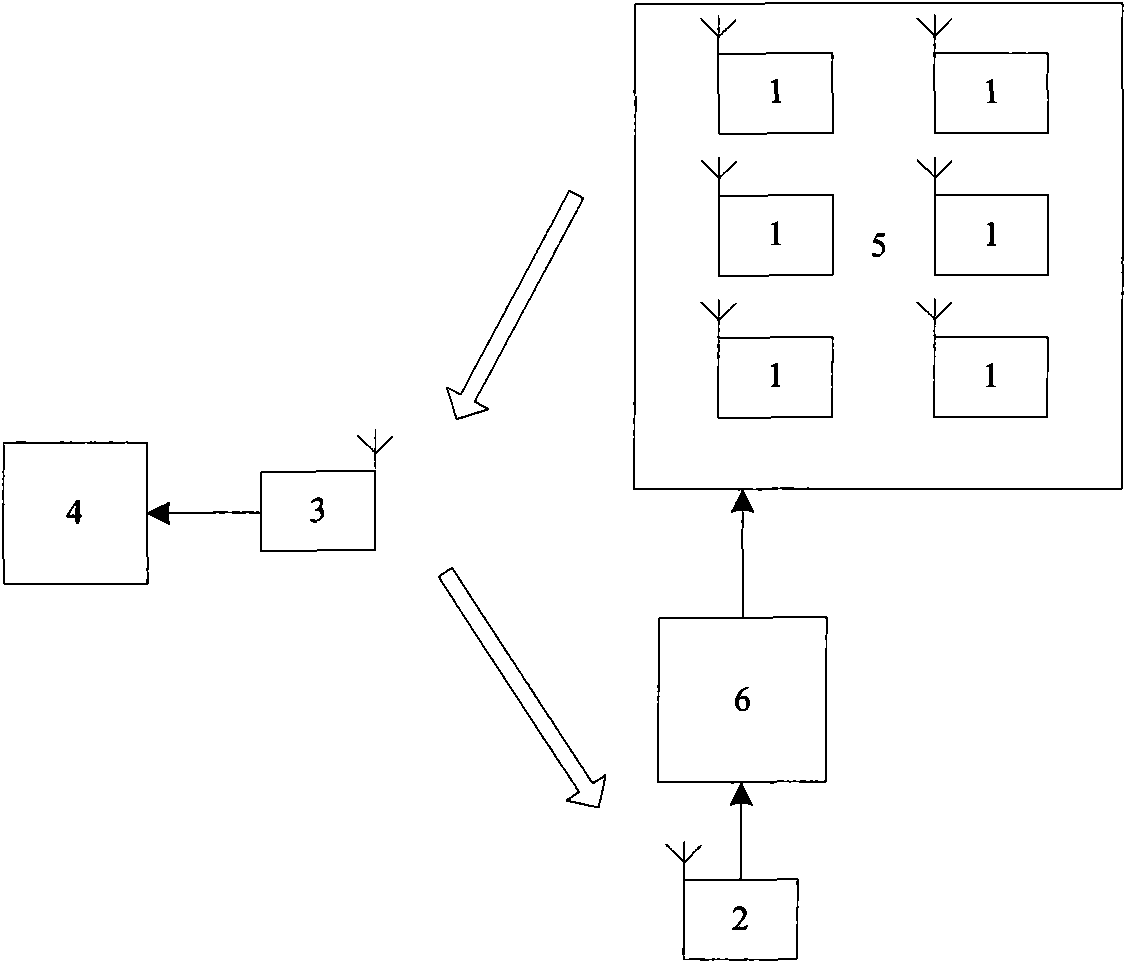

[0029] Such as figure 1 As shown, this embodiment is provided with 6 sensor node devices 1, drive node devices 2, network coordinator device 3 and monitoring computer 4. 5 machine tools, 6 motion controllers

[0030] The sensor node device 1 and the drive node device 2 are installed on the machine tool 5 as network nodes, and the sensor node device 1 and the drive node device 2 form a wireless network. Among them, the sensor node device 1 is responsible for collecting sensor signals, and the drive node device 2 is responsible for sending processing control signals to the motion controller 6 of the machine tool 5 .

[0031] Monitoring computer 4 installs monitoring software developed based on the windows operating system.

[0032] All operations in the processing process are based on the man-machine interface of the monitoring software, such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com