Switching mechanism

A locking mechanism, switch shaft technology, applied in the direction of electric switch, contact drive mechanism, power device inside the switch, etc., can solve the problems of arc formation and disconnection, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

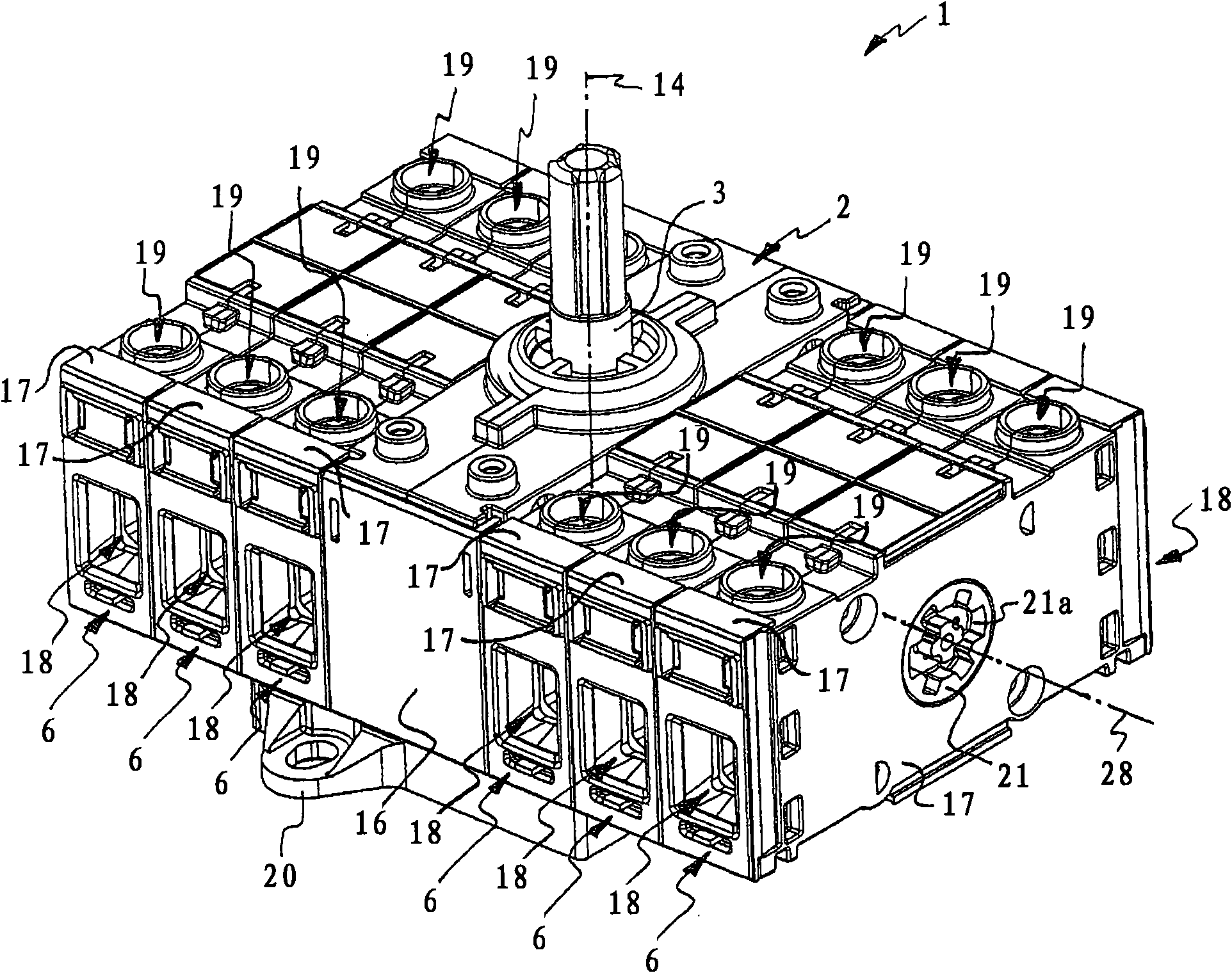

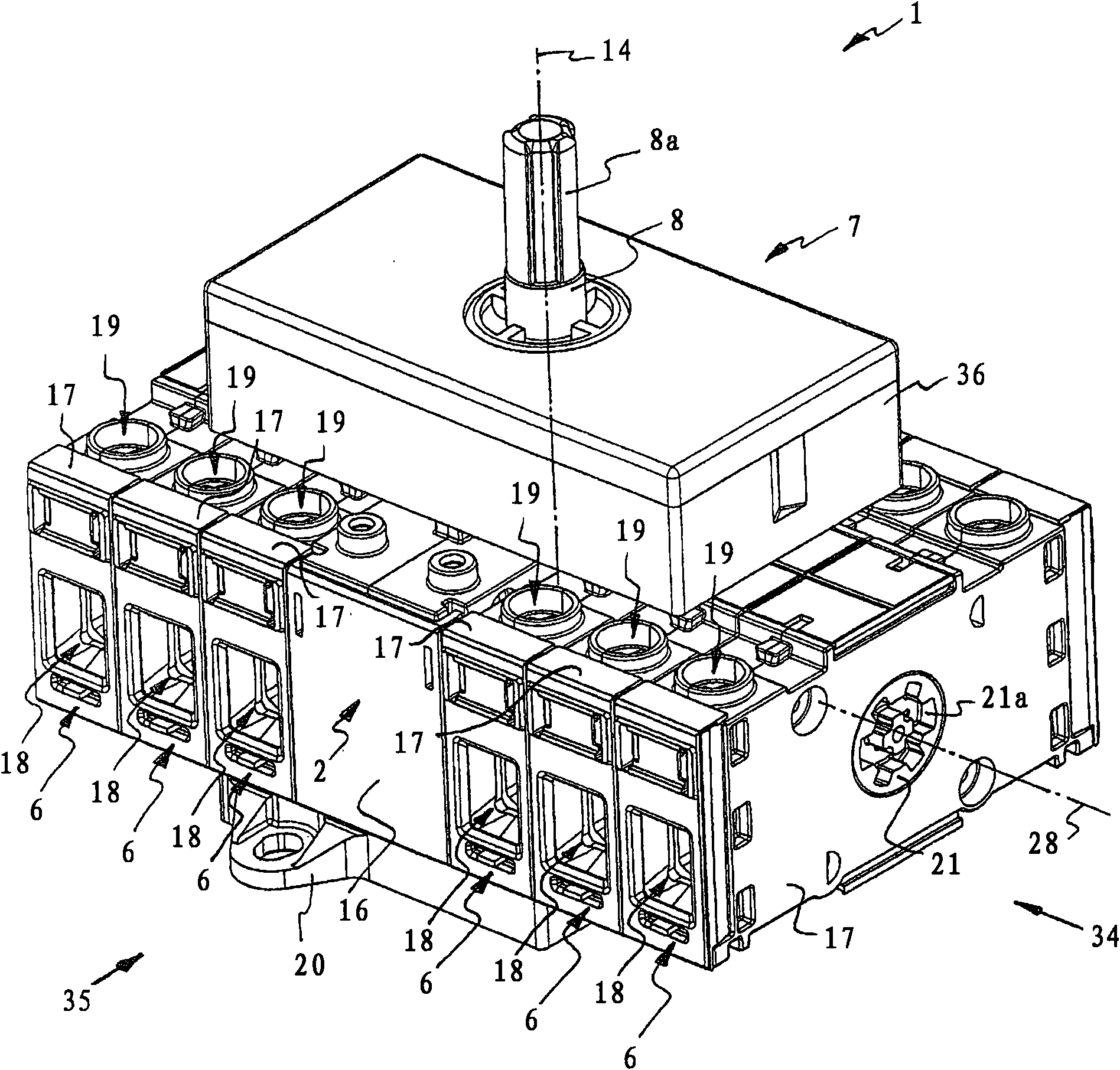

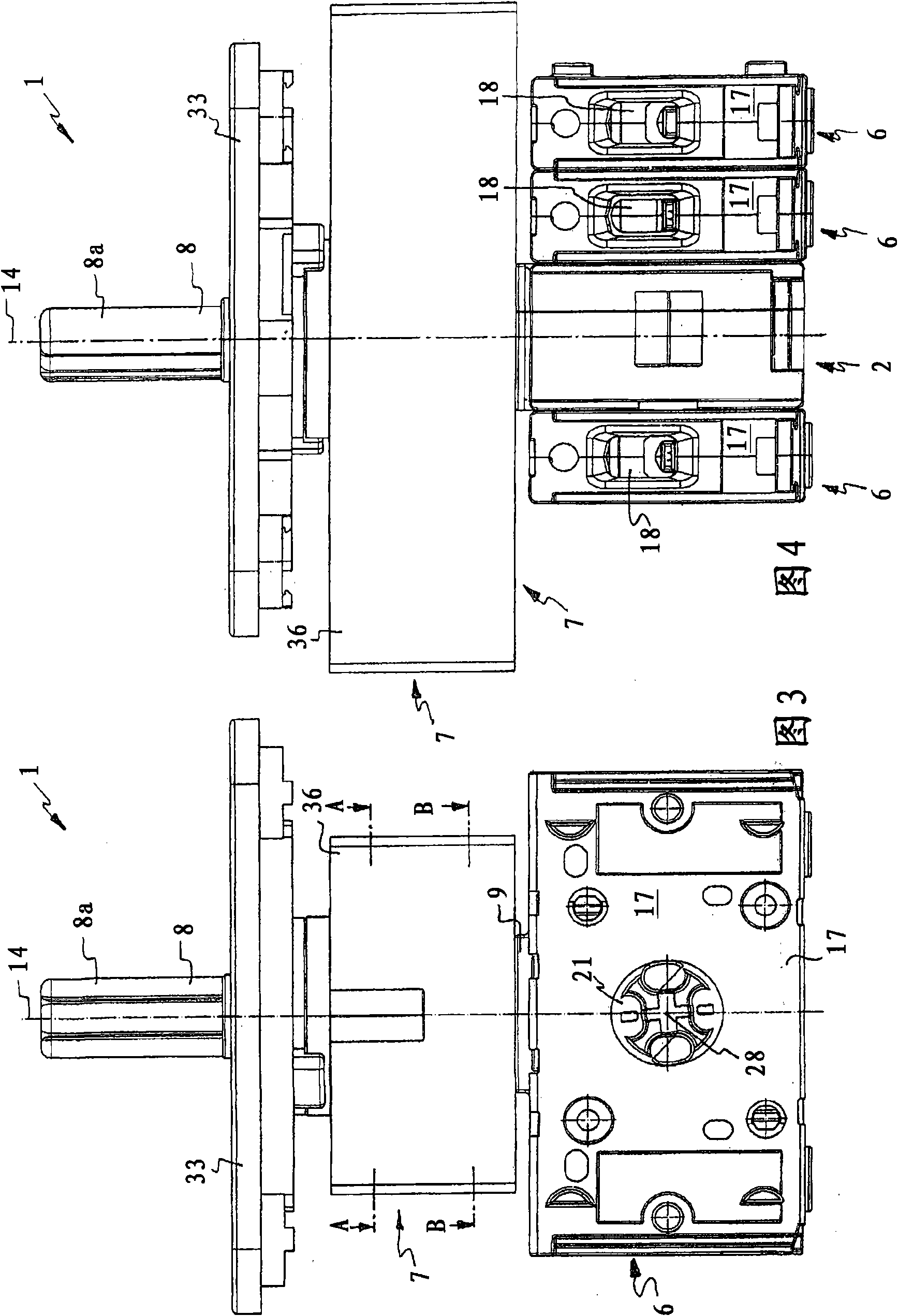

[0049] figure 1 An electrical switch locking mechanism 1 is shown, which has a main locking mechanism 2 in which a drive shaft 3 is rotatably mounted in a substantially cuboid-shaped housing 16 . Any number of switch modules 6 are arranged on both sides of the main locking mechanism 2 . In this embodiment, there are three switch modules 6 on the left side and the right side of the main locking mechanism 2 respectively, which have a substantially rectangular parallelepiped housing 17, and these modules are respectively coupled with adjacent switch modules 6 through coupling devices 21 .

[0050] like Figure 8 As shown in the vertical sectional view of such a switch module 6, in each housing 17 of the switch module 6 there is provided a substantially cylindrical contact carrier 5 which is rotatably supported about an axis of rotation 28. Two first contact sections 24 made of an electrically conductive material are arranged in the contact carrier 5 , for example made of plast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com