Manufacture of electric motor component

一种定子、定子极的技术,应用在电动组件、电气元件、磁路静止零部件等方向,能够解决未最大化可用安装空间等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

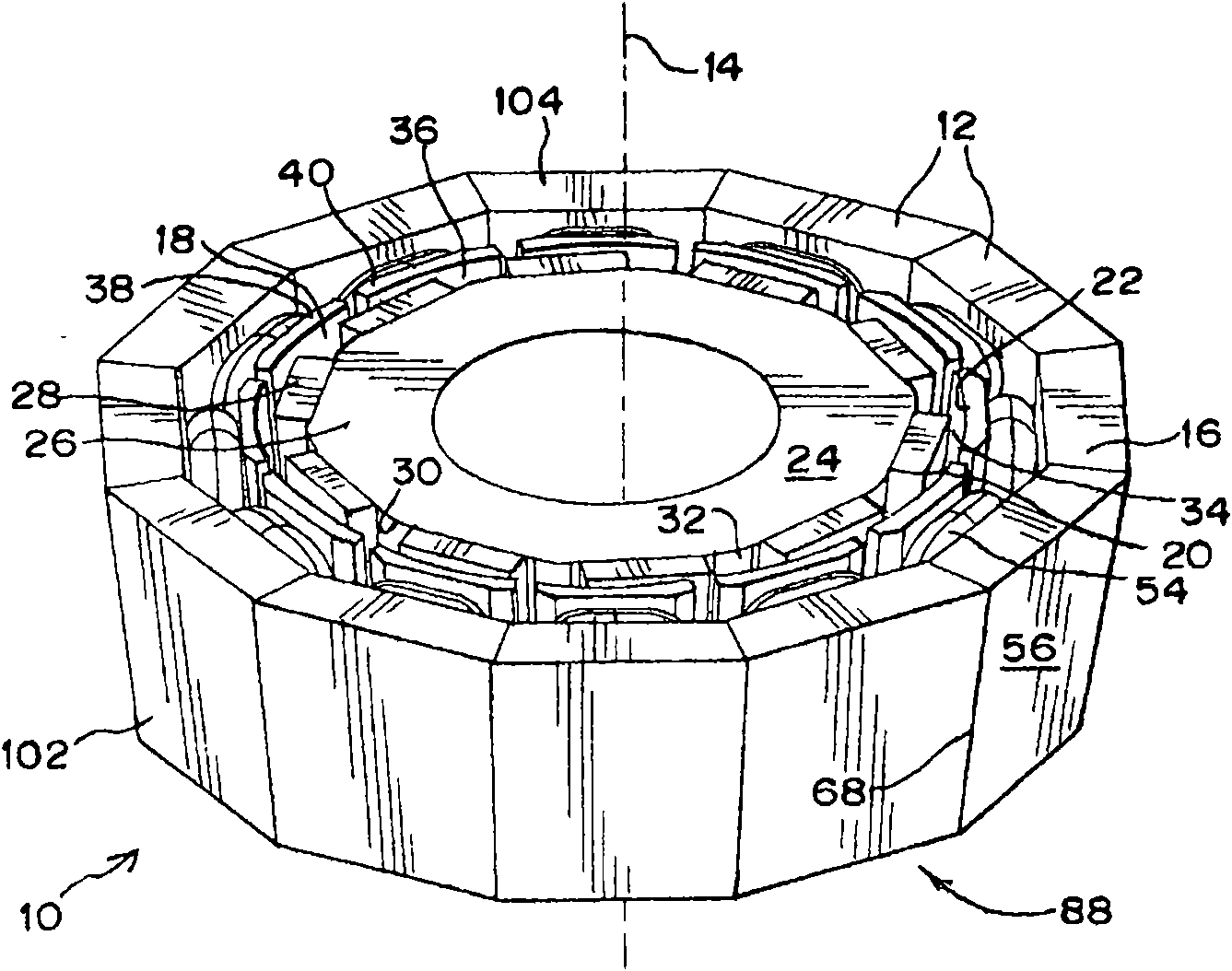

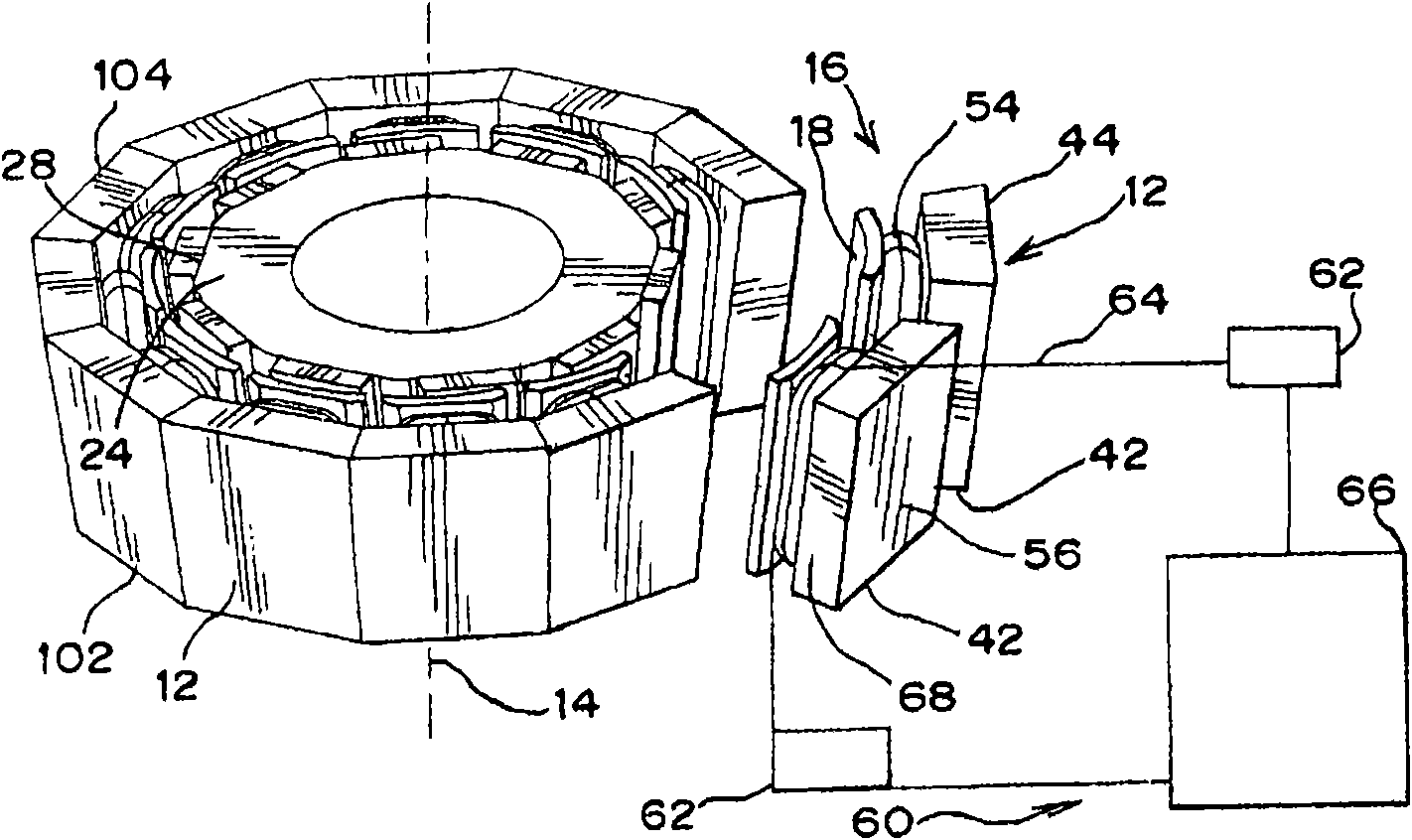

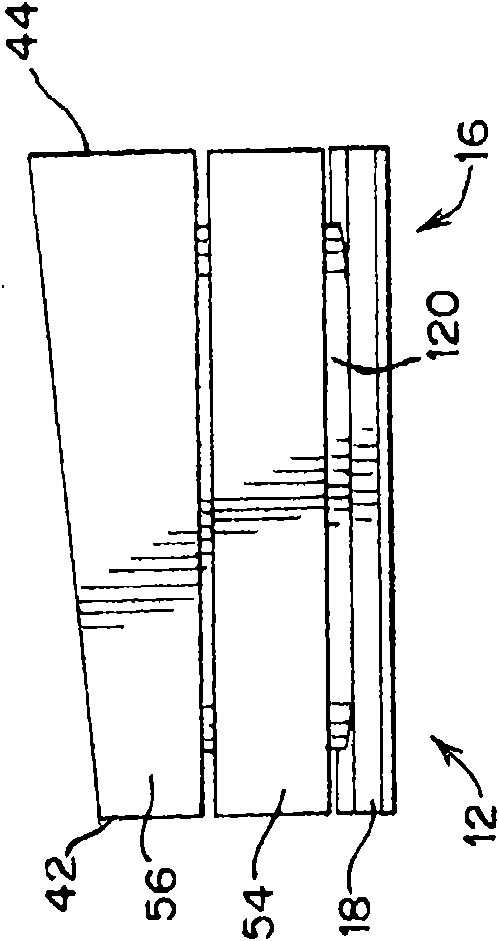

[0024] refer to figure 1 , the conical stator 10 includes a plurality of stator poles 12 assembled circumferentially about a stator axis 14 . Each pole 12 includes modular molded teeth 16 . The tooth 16 includes a stator face 18 and a tooth body 120 ( Figure 3B ). The stator face 18 has a generally rectangular shape inclined at an axial angle to define a conical inner surface 20 which defines a rotor volume 22 . The rotor 24 is rotatably mounted in the rotor space. The rotor 24 is axially aligned along the axis 14 of the stator and held in place for rotation in the rotor space by bearings or the like (not shown). The rotor includes a core 26 having a plurality of magnets 28 arranged along an outer perimeter 30 . The magnets 28 are isolated from each other by a divider 32 . Each magnet 28 defines a pole on rotor 24 . Outer perimeter 30 is precisely machined to maintain a predetermined clearance 34 between rotor 24 and stator 10 .

[0025] The stator 10 partially surrou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com