Electric kettle

A technology for electric kettles and kettle bodies, which is applied in pouring spouts, water boiling utensils, kitchen utensils, etc. It can solve the problems of no pressure relief device, slow liquid outflow, and personnel burns, etc., and achieves a simple and reasonable structure and wide application range. Wide range and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

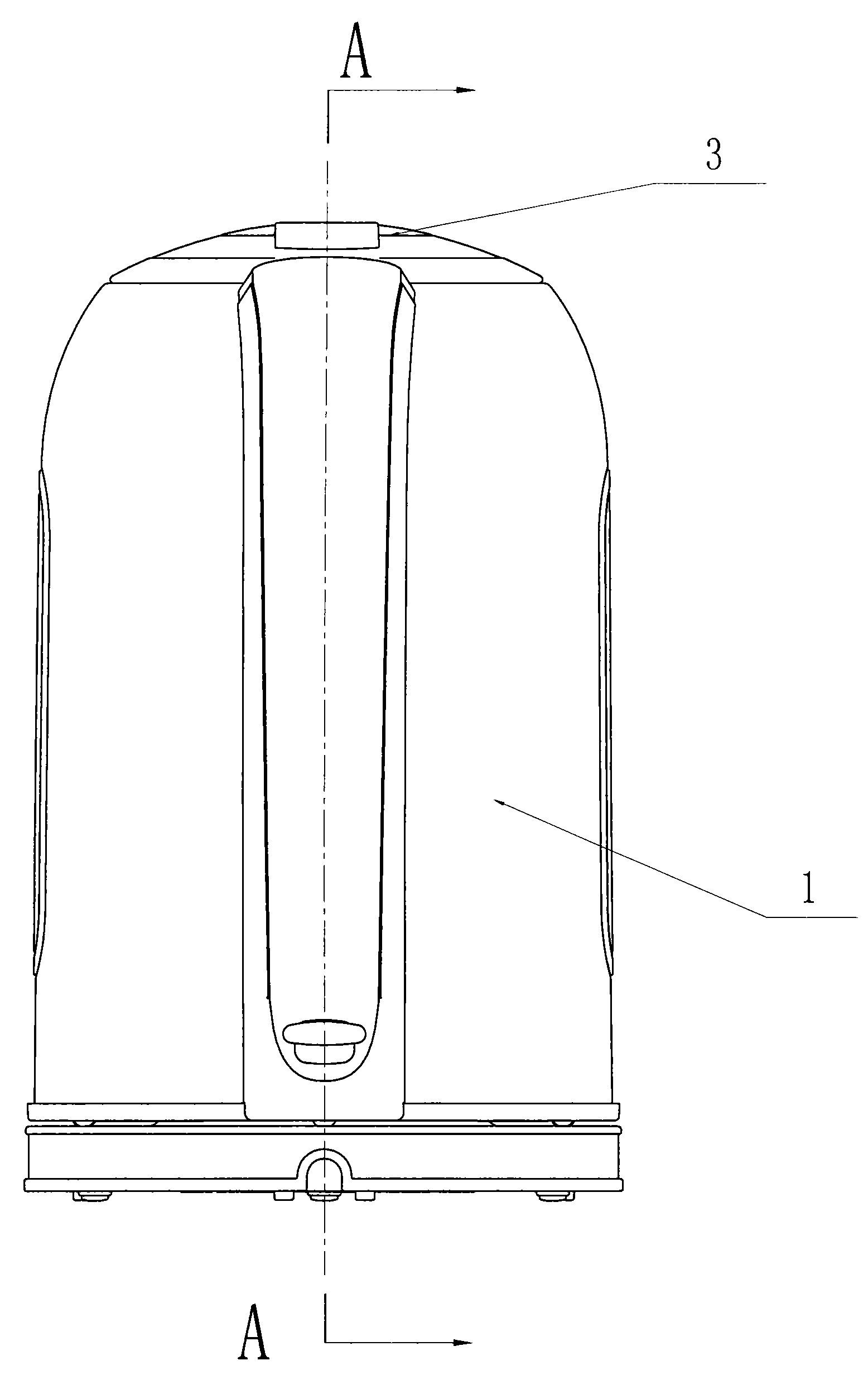

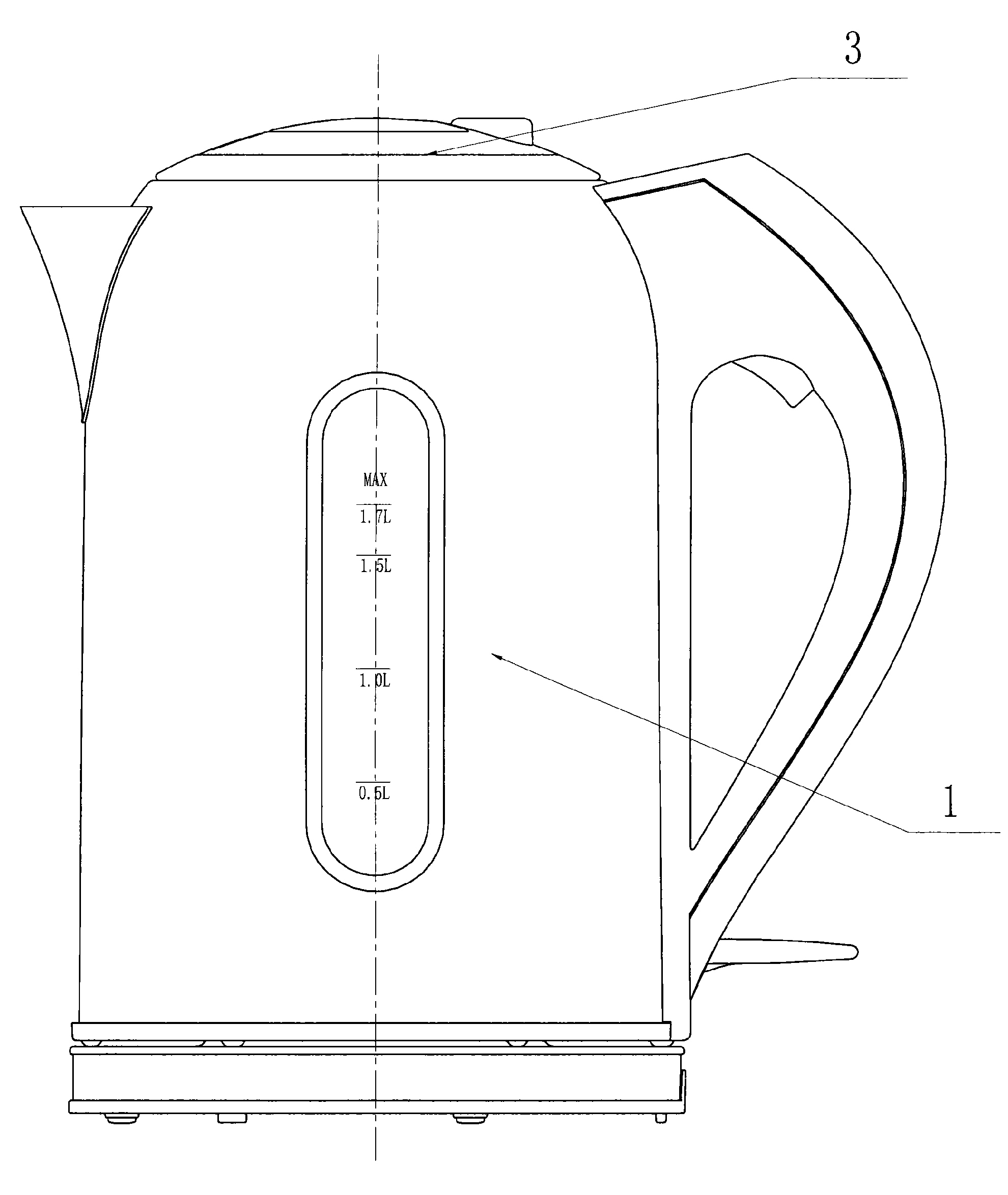

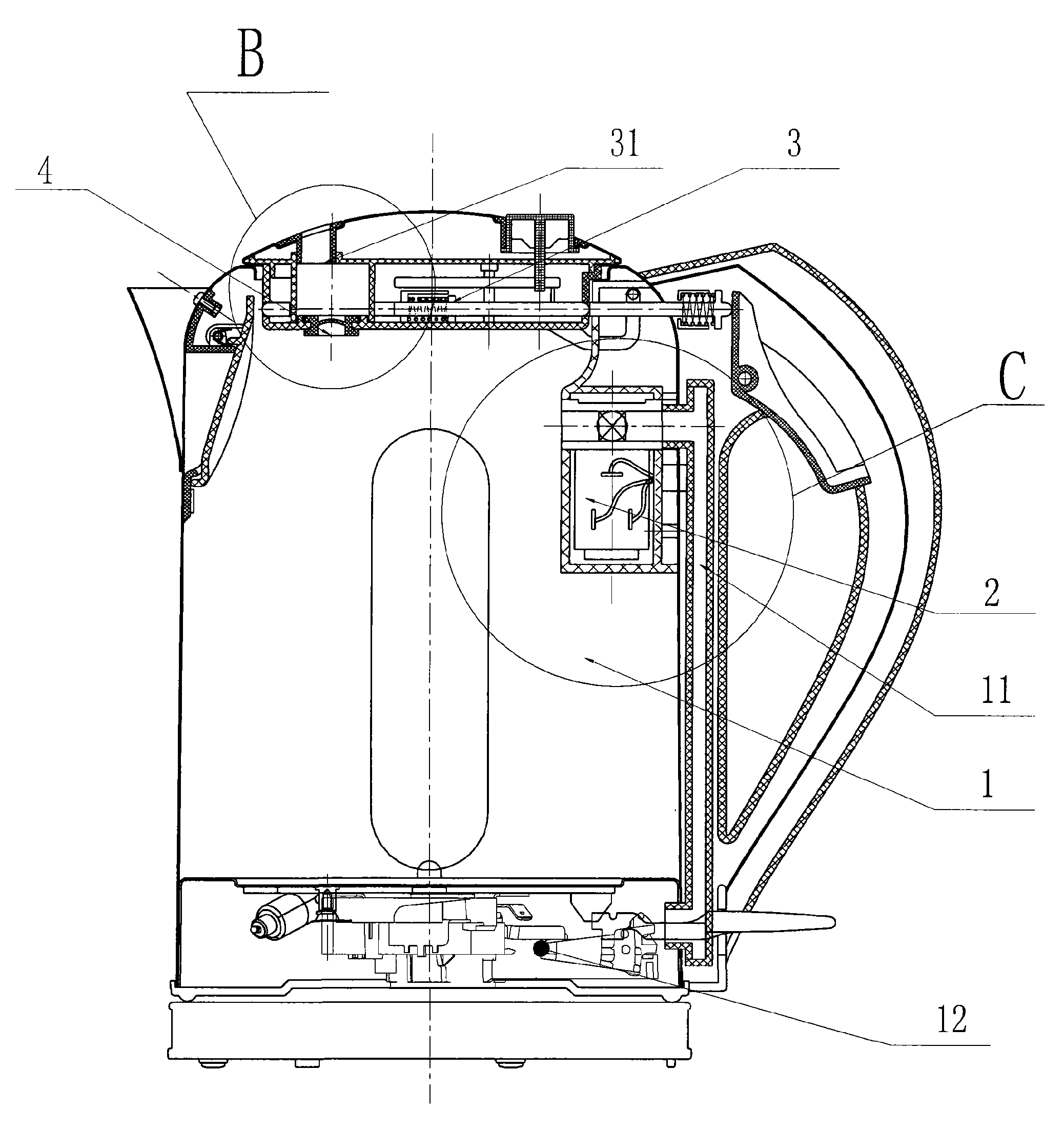

[0024] The structure diagram of the present invention is as figure 1 , 2 , 3, 4, 5, 6, and 7, including a pot body 1 and a pot cover 3, wherein the spout water hole of the pot body 1 is equipped with a spout sealing device 5, and the pot cover 3 is equipped with a pressure relief device. Device 4, the pot lid 3 is provided with a pressure relief hole 31 communicating with the atmosphere, the hollow cavity of the pot body 1 communicates with the pressure relief hole 31 on the pot lid 3 through the pressure relief device 4, and the handle of the pot body 1 is installed Water pouring control switch 16 is arranged, and the kettle spout sealing cover 5 is connected with an end of the driving device that controls it to open, and the other end of driving device is connected with pouring water switch 16.

[0025] In this embodiment, the above-mentioned driving device includes a connecting rod 32 arranged on the pot lid 3 and a push rod 15 arranged on the kettle body 1, one end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com