Carbon dioxide foaming agent injection device for producing polystyrene extruded sheet and injection method thereof

A carbon dioxide and polystyrene technology, applied in the field of injection methods, can solve problems such as difficulty in ensuring accurate and quantitative delivery of carbon dioxide, and achieve uniform and fine cell distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

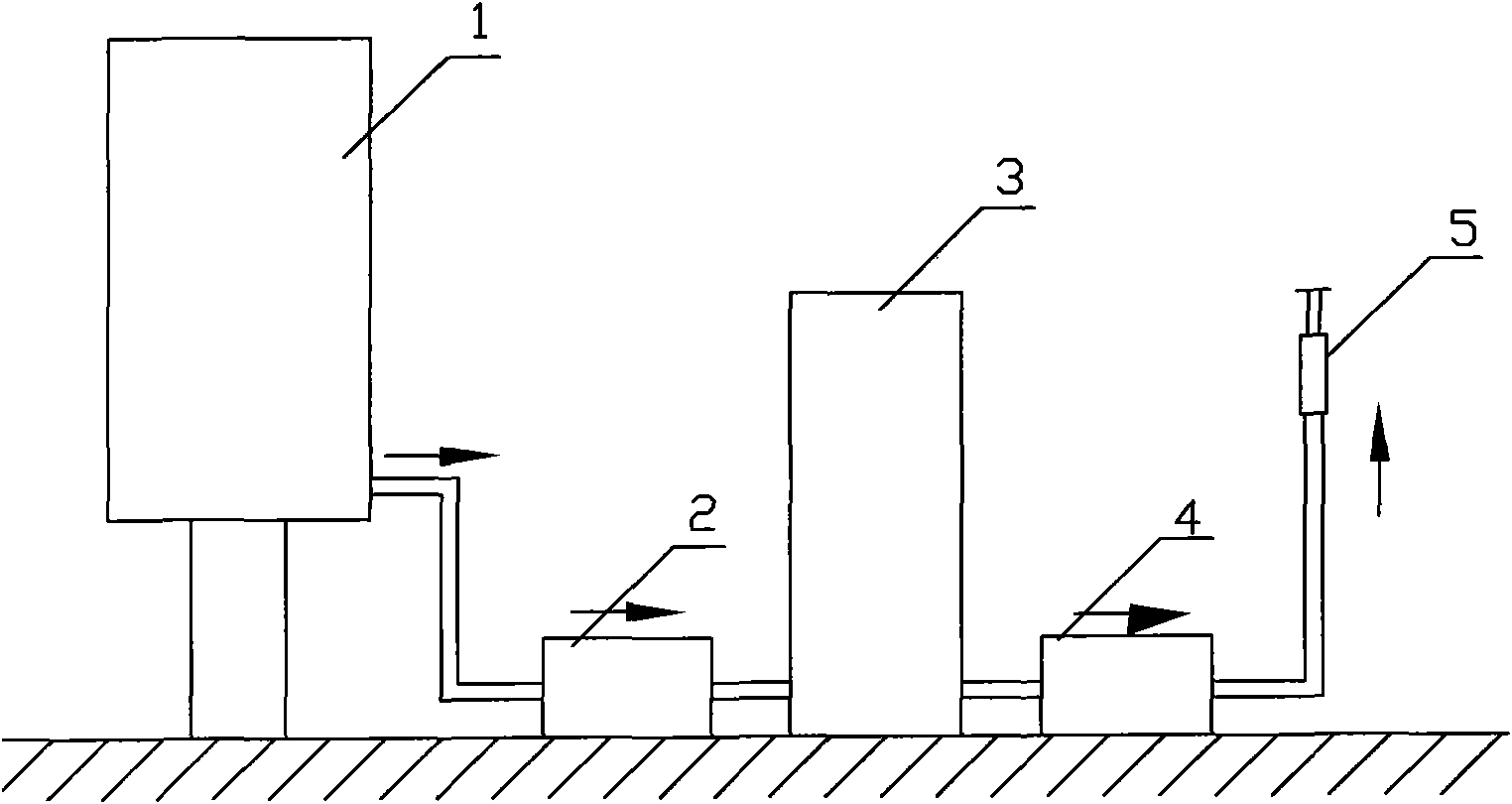

[0013] Refer to attached figure 1 The carbon dioxide blowing agent injection device for polystyrene extruded board production includes a carbon dioxide storage tank 1, a primary metering pump 2, a carbon dioxide buffer tank 3, a secondary metering pump 4 and a one-way valve 5. The carbon dioxide storage tank 1 is a carbon dioxide generator. The source of the foaming agent is placed at a distance of 1.5-2m from the ground, which is a pressure-resistant storage tank; there is a delivery pipe between the output end of the carbon dioxide storage tank 1 and the primary metering pump 2, and the other end of the primary metering pump 2 passes through the delivery pipe. The input end of the carbon dioxide buffer tank 3 is connected, the output end of the carbon dioxide buffer tank 3 is connected with the secondary metering pump 4 through a delivery pipe, the other end of the second metering pump 4 is provided with a delivery pipe connected to the extruder, and the One end of the deliv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com