High temperature resistant electrolyte, preparation method thereof, and non-solid electrolyte tantalum capacitor

A tantalum capacitor and electrolyte technology, applied in the field of electrolyte, can solve problems such as easy gasification of working electrolyte and easy cracking of the shell, so as to prevent cracking of the shell, improve mechanical strength, and improve high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

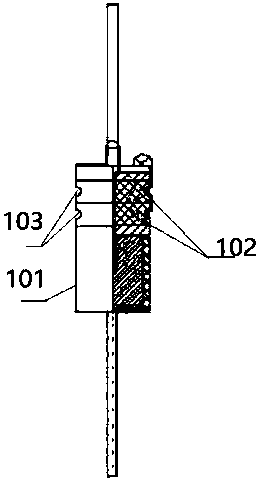

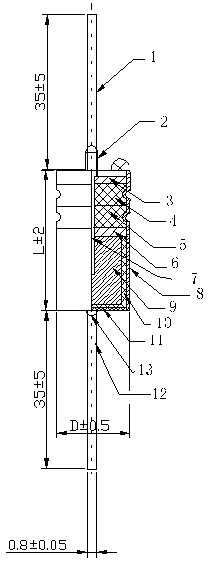

Image

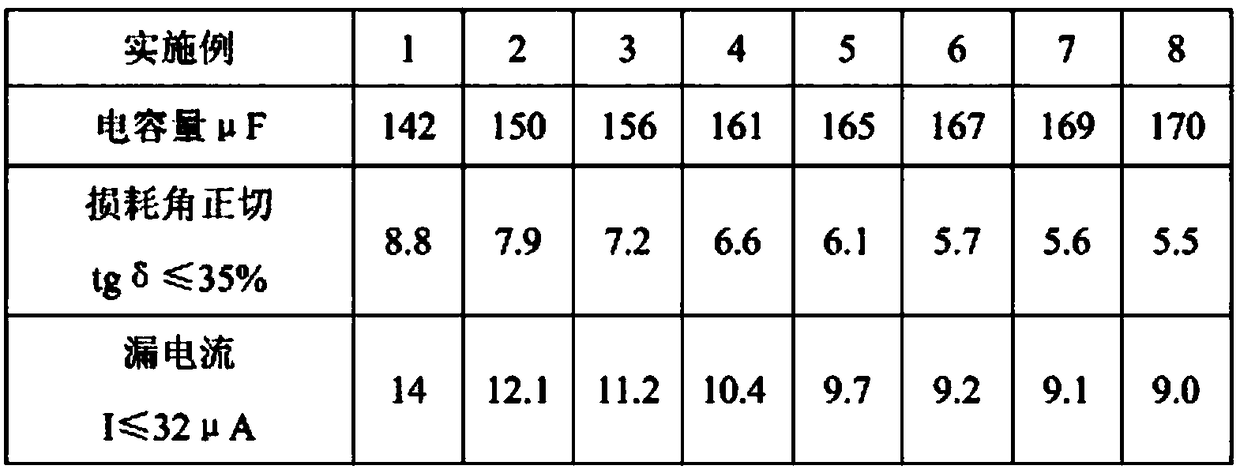

Examples

Embodiment 1

[0030] This embodiment provides a method for preparing a high temperature resistant electrolyte, comprising the following steps:

[0031] S1. Preparation of base liquid: Mix 38 parts of 98% concentrated sulfuric acid and 62 parts of deionized water, specifically 20ml of 98% concentrated sulfuric acid and 60ml of deionized water, then add 1g of boric acid, stir at room temperature to obtain the base liquid;

[0032] S2. Preparation of working solution: mix 150ml of silica sol, 2g of CuSO and 10% chloroplatinic acid of 1.5ml successively according to weight percentage, then add 98% concentrated sulfuric acid of 50ml and stir at normal temperature, finally add 1g of boric acid to obtain working solution liquid.

[0033] Among them, the model of silica sol is 0101, and the performance indicators are as follows: pH value is 9~9.7, resistivity of silica sol P30℃≥200Ω.cm, density is 1.2g / cm3, appearance is milky white, translucent, latex-like liquid, No mechanical impurities and fl...

Embodiment 2

[0035] This embodiment is basically the same as Embodiment 1, except that 2 g of boric acid is added in step S1.

Embodiment 3

[0037] This example is basically the same as Example 1, except that 3 g of boric acid is added in step S1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com