Candy bar folding packing machine

A packaging machine and candy technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve problems such as low production efficiency, unsanitary, and inability to meet large-scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

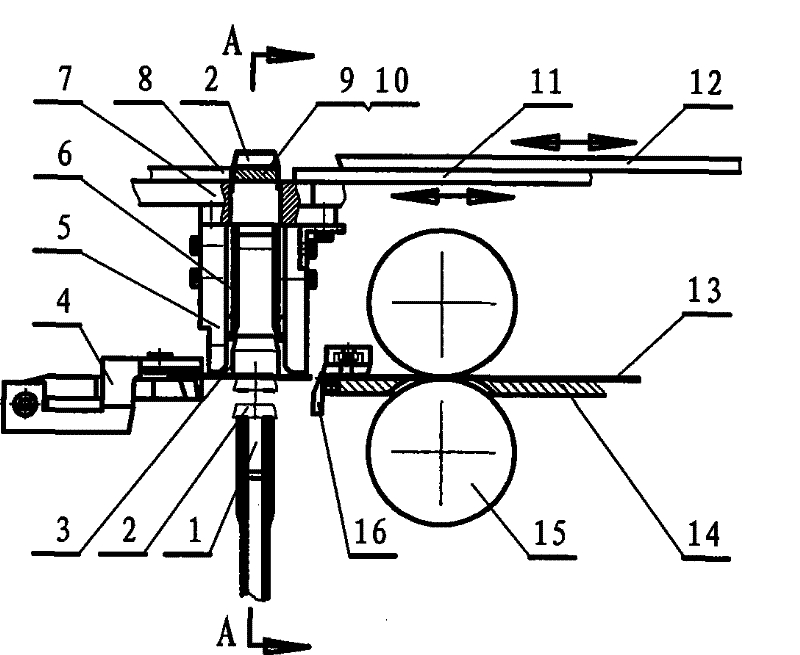

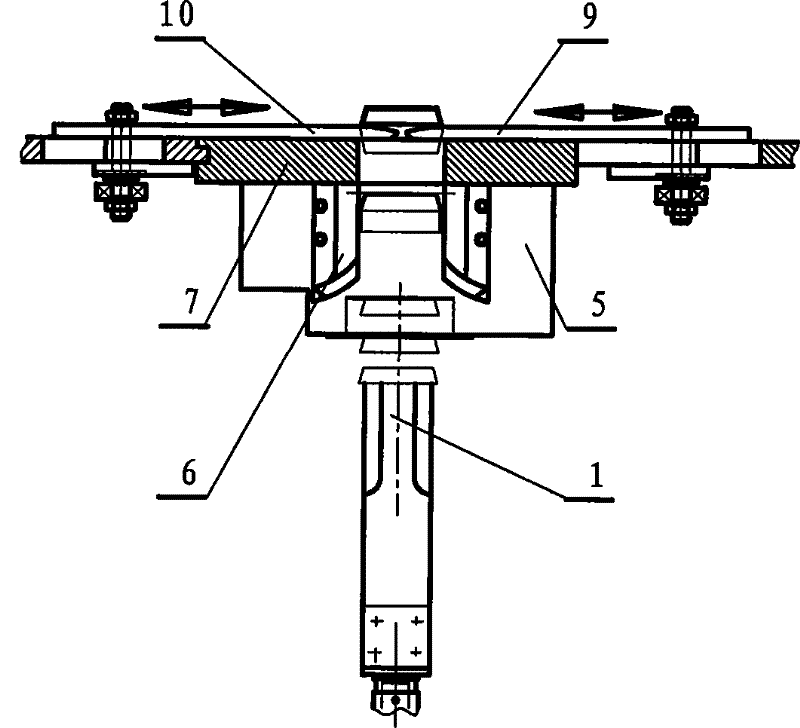

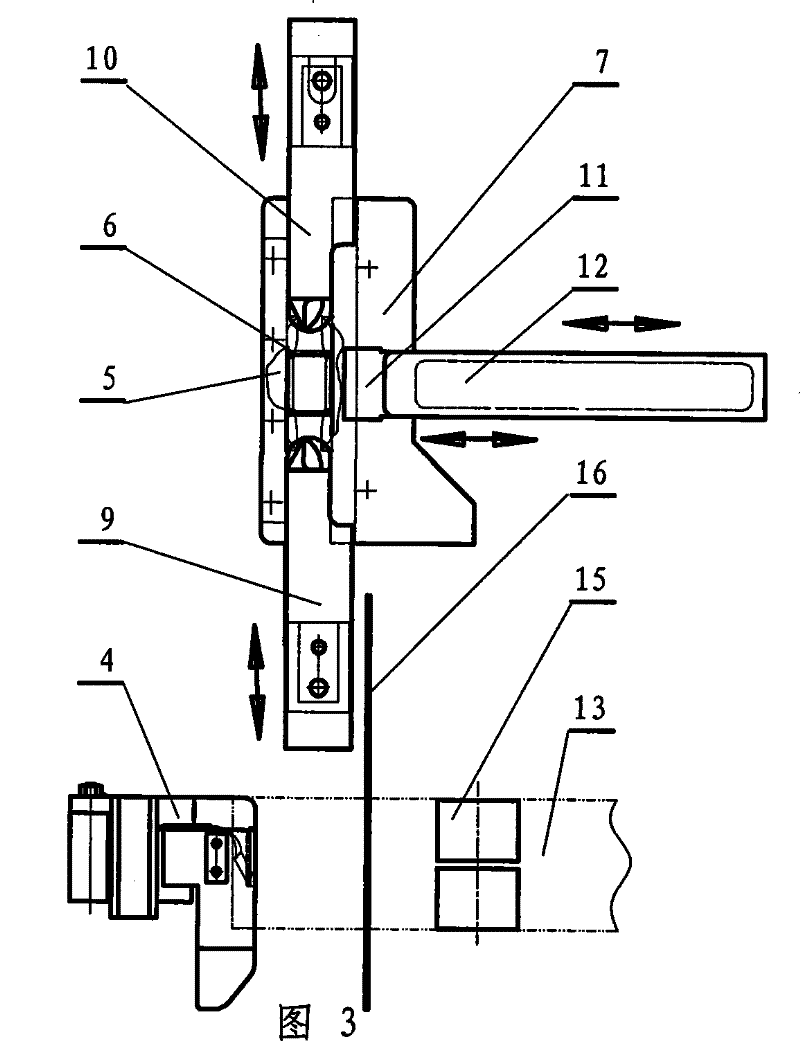

[0014] exist figure 1 , figure 2 and image 3 In the shown block candy folding packaging machine, a paper feed roller 15 and a paper clamp 4 are arranged on the packaging machine body, and a paper tape scissor 16 is arranged between the paper clamp 4 and the paper feed roller 15 . The paper feeding roller 15 adopts a pair of roller structure that rolls against each other. Under the twitching of the paper feeding roller 15, the wrapping paper tape 13 is pinched along the upper plate of the paper tape supporting plate 14 facing the scissors of the paper tape scissors 16; Scissors 16 are positioned at the plate end of paper tape pallet 14, and it comprises fixed blade and movable blade. The paper clamp 4 can open and clamp the block wrapping paper 3 cut into a certain specification by the scissors, and send the block wrapping paper 3 to the opening of the folding box with the opening downward. A pair of folding box side plates 5 arranged in parallel on the top, a folding box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com