LED lamp radiator with improved structure

A technology of LED lamps and radiators, which is applied to semiconductor devices of light-emitting elements, cooling/heating devices of lighting devices, electric solid devices, etc. It can solve problems such as breakage, failure to keep, increase costs and defective products, and achieve cost reduction , The effect of taking into account the production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

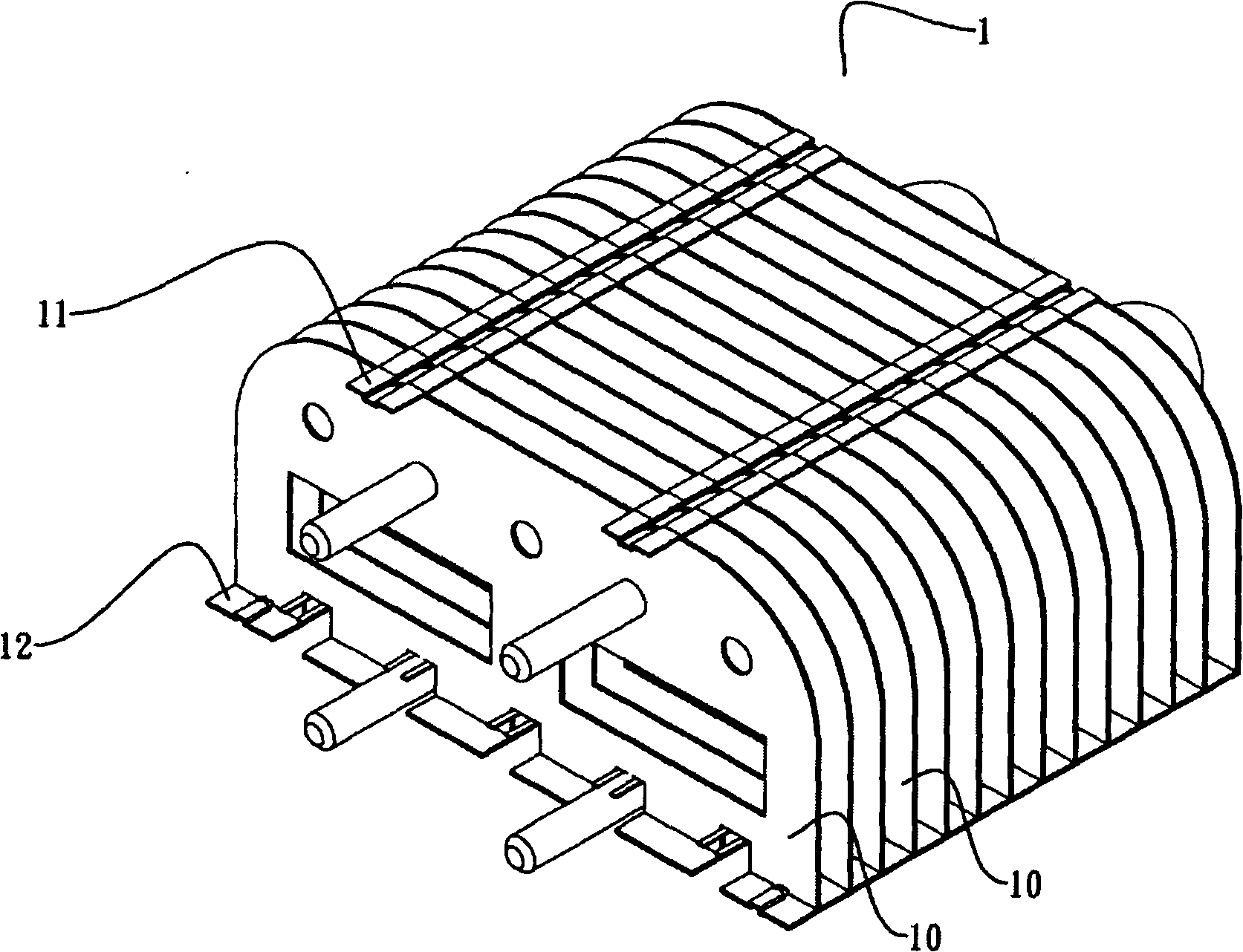

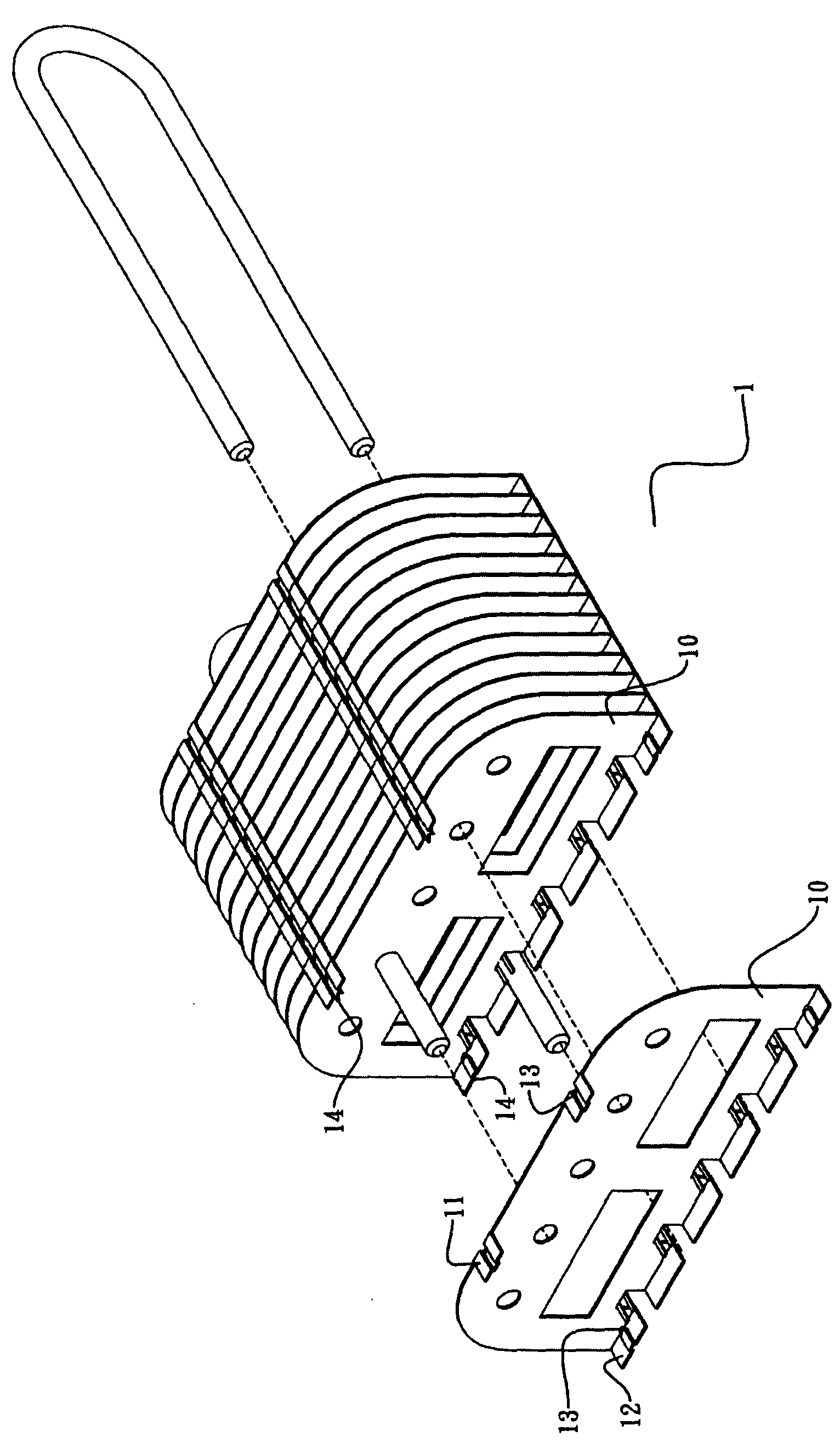

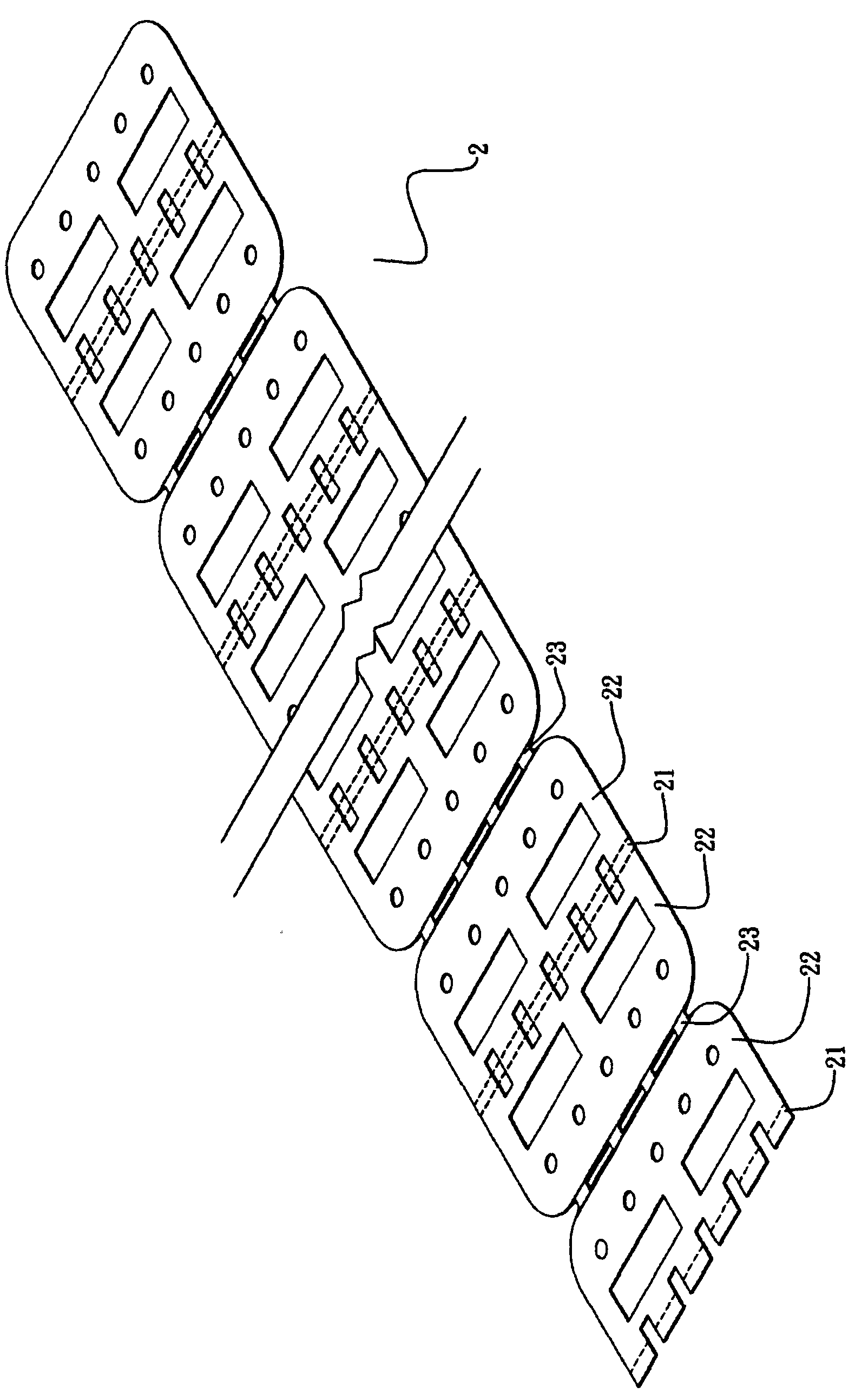

[0031] Improved structure of LED light radiator, refer to Figure 1 to Figure 5 , The radiator 3 includes a radiator, the radiator is formed by a long strip of heat-conducting material by a machine, the radiator includes a plurality of radiating units, the radiating units are connected into a whole, each radiating unit in turn from the bottom end surface The area 21, the wall end area 22, the top end area 23, and the wall end area 22 are integrally connected. After being formed, each wall end area 22 has the same interval length and is parallel to each other. The interval between the top end area 23 and the bottom end area 21 The length is the same and perpendicular to each wall end surface area 22, and the interval length of each wall end surface area 22 is greater than the interval length between the top end surface area 21 and the bottom end surface area 23.

Embodiment 2

[0033] Improved structure of LED light radiator, refer to Figure 6 with Figure 7 The heat sink 4 includes two heat sinks 40 and 41, and the structure of each heat sink is the same as the structure of the heat sink in the first embodiment. The two heat sinks 40 and 41 are superimposed and connected up and down, and the bottom end surface area of the upper heat sink 40 of the two heat sinks is superimposed on the top end surface area of the lower heat sink 41.

Embodiment 3

[0035] Improved structure of LED light radiator, refer to Figure 8 The radiator 5 includes two radiators. One radiator 50 has only two wall end areas 22 and a bottom end area 21 connected to the lower ends of the two wall end areas 22, and the other radiator has two wall end areas 22 The number is greater than two, and its structure is similar to the heat sink in the first embodiment. In addition, a chassis 52 is also included. The heat sinks are arranged parallel to each other on the chassis, and the wall end area 22 of each heat sink is perpendicular to the chassis. The surface of the chassis 52 is provided with a plurality of sets of corresponding and upwardly extending fixed feet 53. The two heat sinks are both placed on the chassis 52, and a set of fixed feet 53 is bent inward and pressed against the two wall end areas 22. One of the two ends of the bottom end surface area 21, so that the heat sink is fixed on the chassis 52.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com