Automobile fuel volume non-contact photoelectric sensor

A photoelectric sensor, non-contact technology, applied in the direction of transmission of sensing components, buoy liquid level indicators, etc. using optical devices, which can solve the problems of sensor damage, out of contact, and change of contact surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

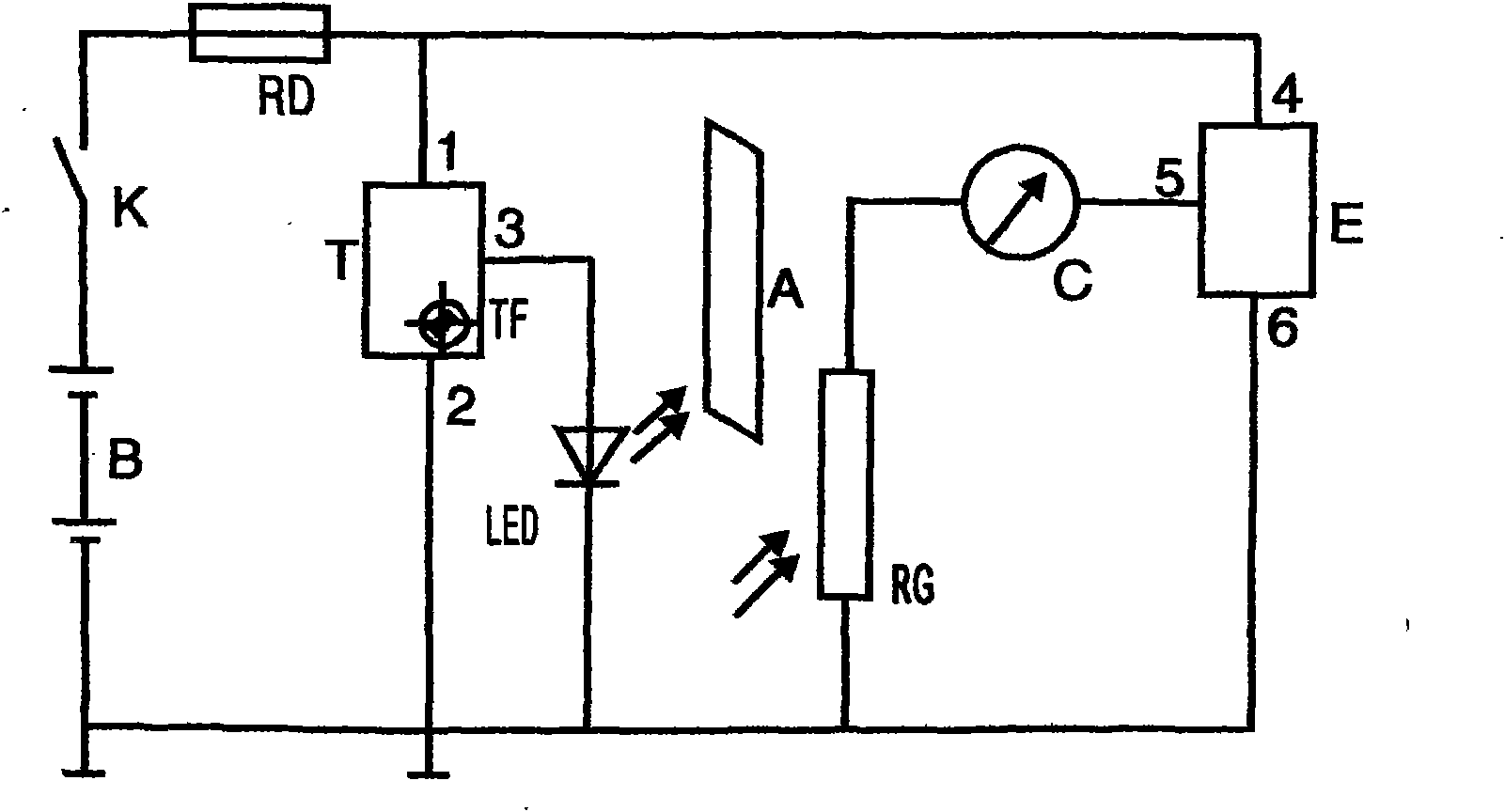

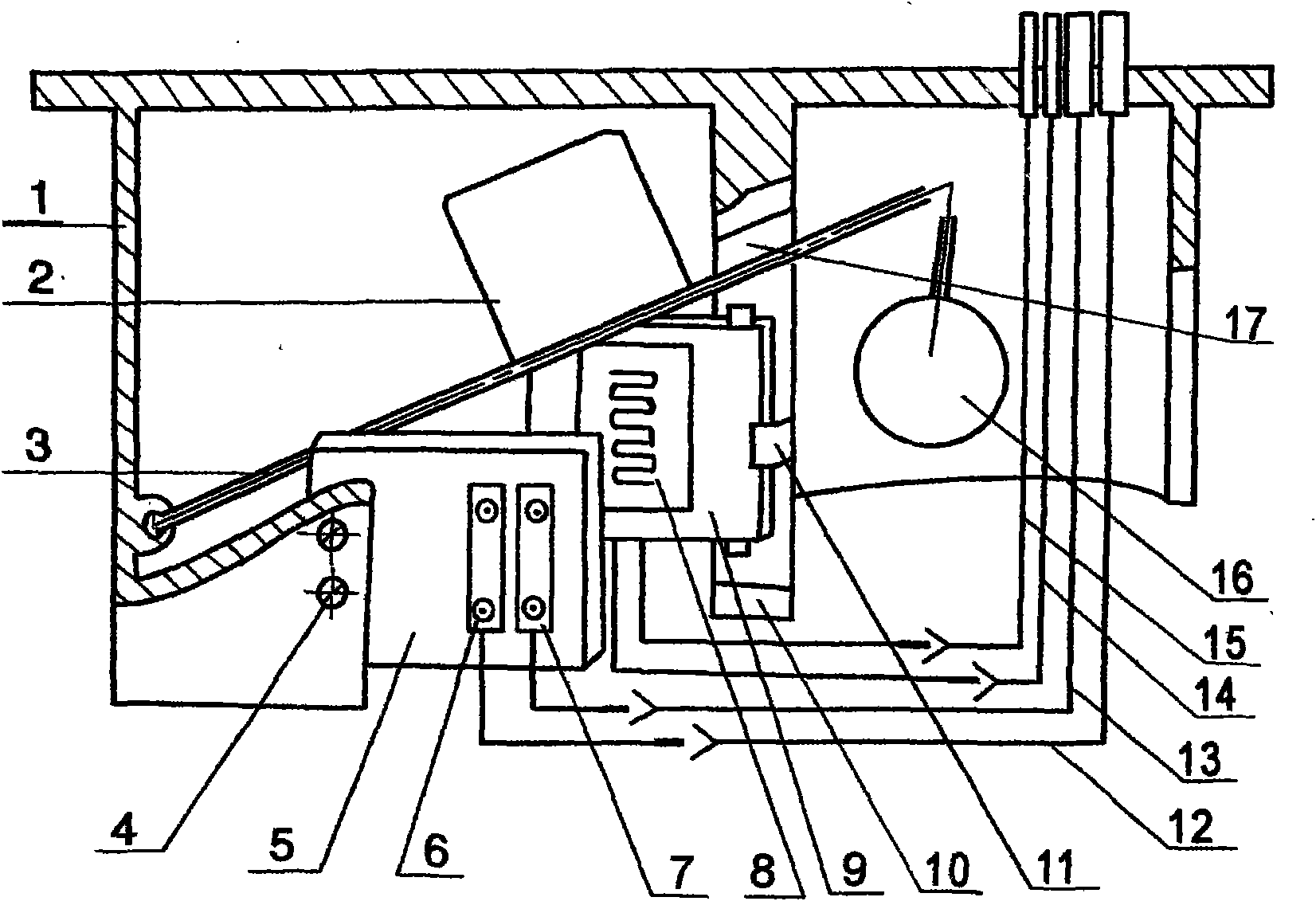

[0009] The non-contact photoelectric sensor of automobile fuel capacity is composed of a float frame 1, a shading plate 2, a float rod 3, a light source 5, a photoresistor 9, and a float 16. The float frame 1 is connected with a fixed photoresistor 9 and a light source 5 . The light source 5 can be one, two, or several (closely arranged) light-emitting diodes (LEDs) welded together and made into a specific emission light (surface).

[0010] figure 2 It is the embodiment of this invention: 1 is the buoy frame, which is reformed on the existing buoy frame, on which the buoy bar 3 hinged holes are set, the elliptical connecting hole of the light source 5 can be moved up and down, the lower limit end 10, the upper limit End 17, the fixed barb 11 of photoresistor 9, and the connecting terminal of lead 12,13,14,15, 5 is light source, is provided with connection hole on it, positive pole circuit 6, negative pole circuit 7, and light-emitting diode (LED) is welded on On its circuit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com