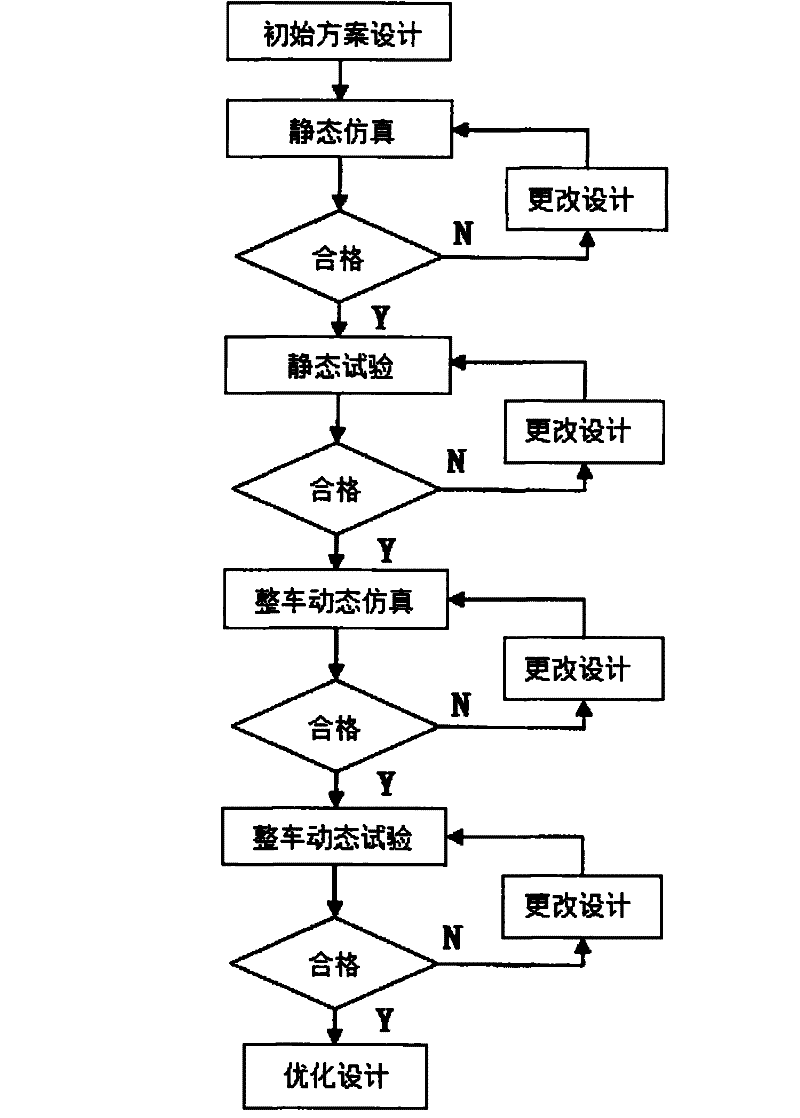

Construction-vehicle cab with novel roll-over protection structure, and dynamic design method thereof

A technology of protection structure and dynamic design, applied in the field of engineering vehicle safety cab research, can solve the problems of position control, difficult quality assurance, and processing difficulties in the deformation area, so as to improve the standardization and efficiency, and improve the first pass rate. , the effect of improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

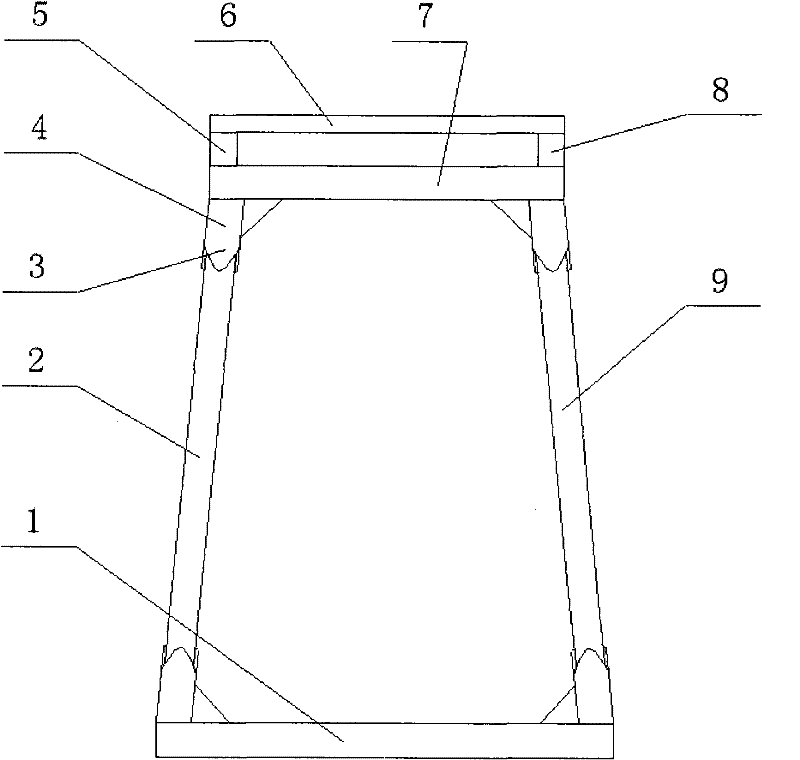

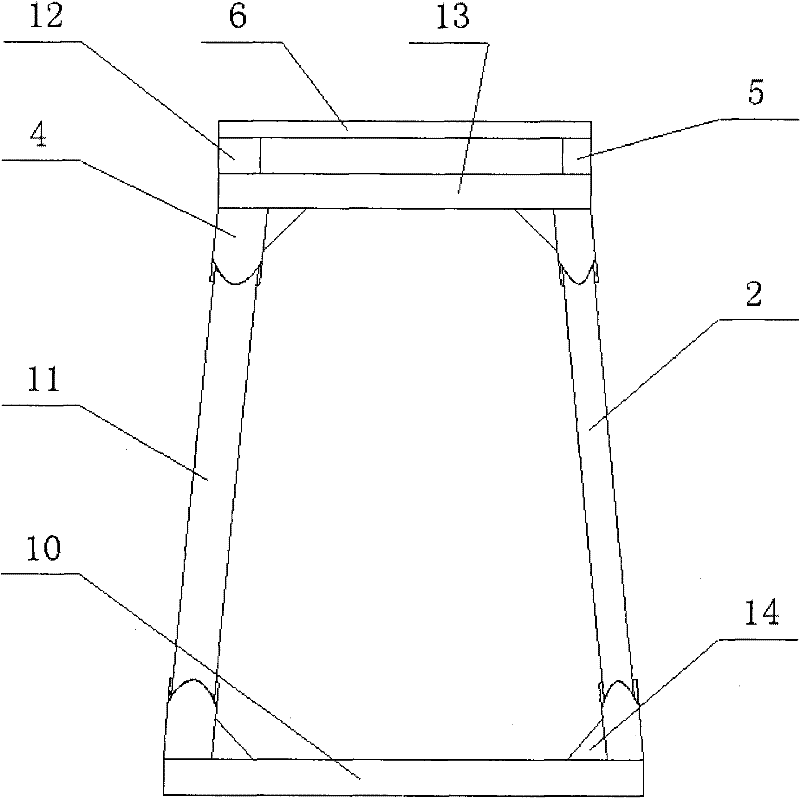

[0042] Two, a kind of preferred embodiment of the engineering vehicle cab with novel rollover protection structure provided by the present invention is:

[0043] The cab frame consists of front upper beam 7, front lower beam 1, left upper beam 13, left lower beam 10, right upper beam 16, right lower beam 15, rear upper beam 20, rear lower beam 19, left front column 2, right front column 9, left Rear column 11 and right rear column 18 are fixedly formed.

[0044] The intensity of the left rear column 11 and the right rear column 18 is greater than that of the left front column 2 and the right front column 9 .

[0045] The outer surfaces of the upper end and the lower end of the left front column 2, the right front column 9, the left rear column 11 and the right rear column 18 are respectively provided with an energy guide sleeve 4 whose cross-sectional shape is consistent with the corresponding cross-sectional shape of each column, and the free end of the energy guide sleeve 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com