Line production drying oven for electrodeless fluorescent lamps

An electrodeless fluorescent lamp and flow operation technology, applied in cold cathode manufacturing, tube/lamp screen manufacturing, electrode system manufacturing, etc., can solve the problems of slow heating, poor removal of harmful materials, low work efficiency, etc. The effect of easy control of heating temperature and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and embodiment describe in detail:

[0035] 1. Overall

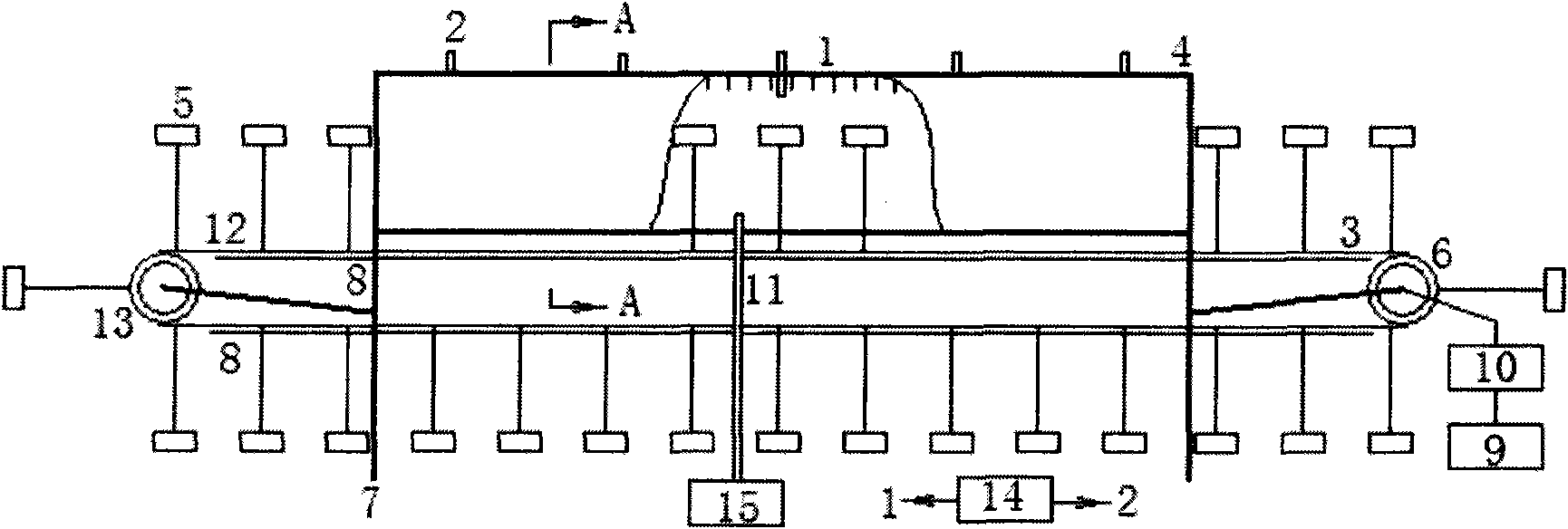

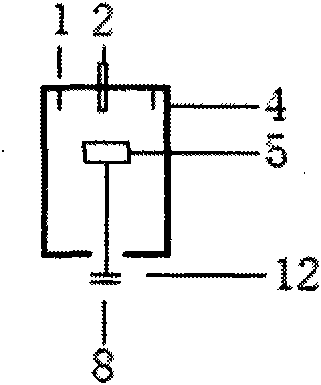

[0036] Such as figure 1 , 2 , 3, the present invention includes electric heating tube 1, thermocouple 2, chain 3, box body 4, bracket 5, driving gear 6, box frame 7, chain track 8, motor 9, reducer 10, blowing pipe 11, bottom plate 12 , driven gear 13, temperature controller 14 and blower 15;

[0037] A box body 4 is arranged on the middle part of the box frame 7, and an electric heating tube 1, a thermocouple 2 and a blower pipe 11 are arranged on both sides of the box body 4, so that the temperature in the box body is sequentially from the inlet to the outlet of the low temperature zone, High temperature zone and low temperature zone;

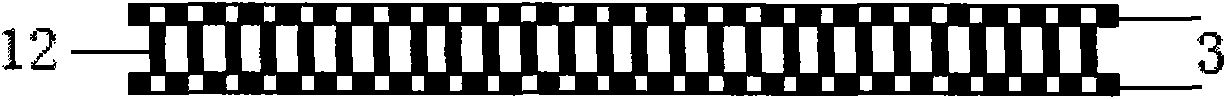

[0038] A driven gear 13 and a driving gear 6 are respectively arranged at the inlet and outlet ends of the box frame 7, and are connected by a double chain 3 between the driven gear 13 and the driving gear 6, and a chain track 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com