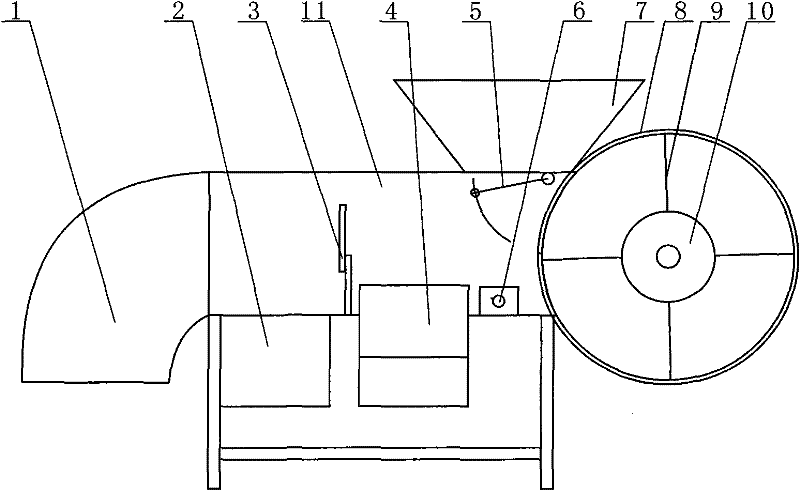

Electric winnowing machine

An air separator, electric technology, applied in solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc. problems, to achieve the effect of facilitating promotion, reducing picking processes, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] Pour the corn into the silo 7, adjust the angle of the feeding adjustment plate 5, and control the falling amount of the corn, so as to avoid the excessive falling amount that is not conducive to picking, turn on the stepless adjustment controller 6, the prime mover 10 rotates, and adjust the stepless adjustment controller 6 , so that the air volume is relatively large. Because the blades 9 are not symmetrically arranged, the bellows 8 will vibrate due to the unbalanced rotation. This vibration is conducive to the uniform fall of the corn from the adjustment feed adjustment plate 5, and the wind enters the sorting bin 11 to blow When the corn passes through the corn, the corn with a larger specific gravity falls quickly, is blocked by the adjustable sorting baffle 3, and falls into the primary separation outlet 4, and the corn with a smaller specific gravity, dust, and sundries are blown by the wind through the adjustable sorting baffle 3, The heavier corn falls into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com