Pre-install auto-glass safety hammer

An automotive glass and safety hammer technology, applied in vehicle safety arrangement, pedestrian/occupant safety arrangement, vehicle parts, etc., can solve the problems of missing safety hammer, easy loss, casualties, etc. The effect of less material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention is described in further detail below in conjunction with accompanying drawing:

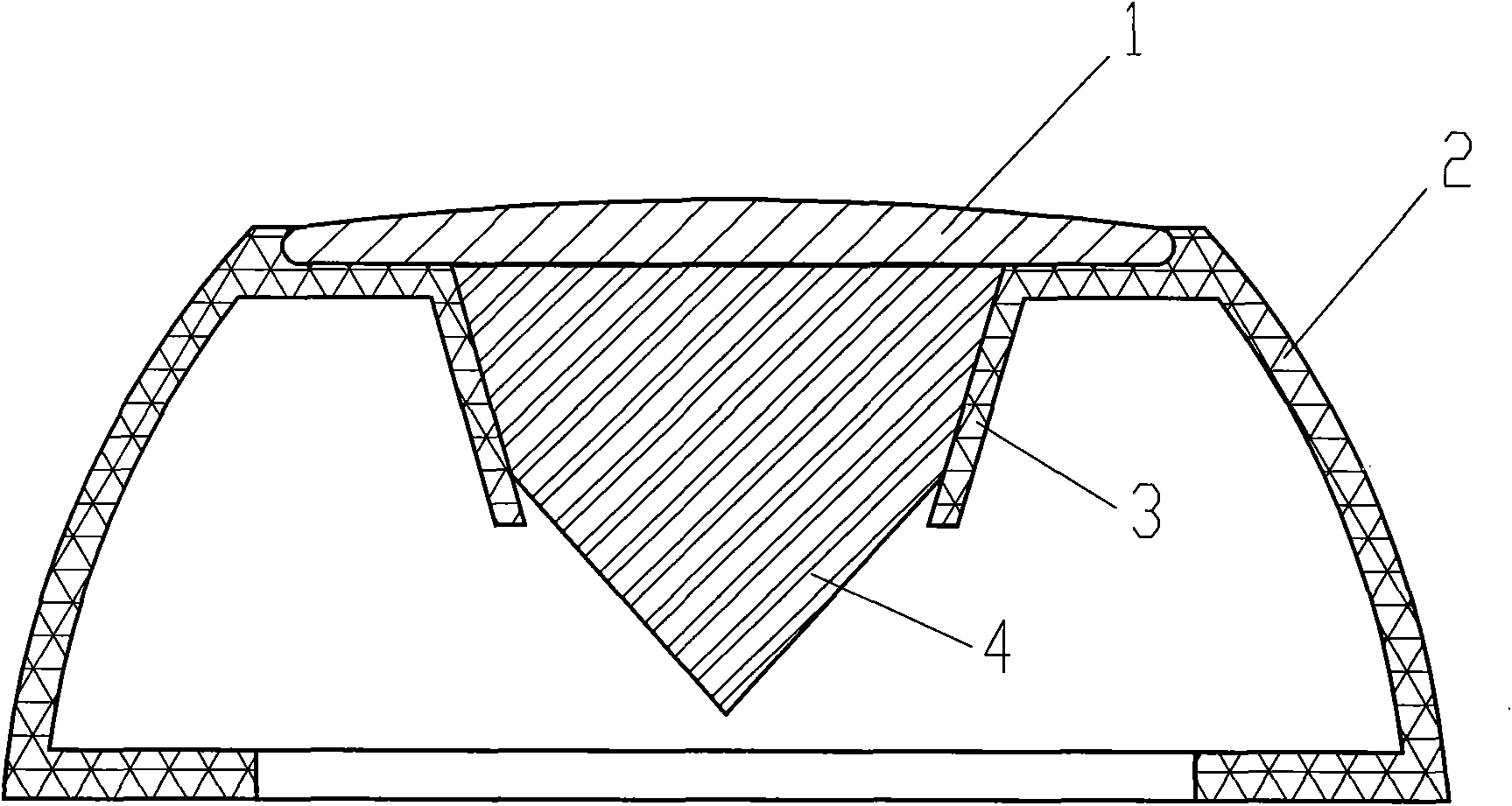

[0011] Such as figure 1 As shown, the safety hammer of the present invention includes an elastic bowl body 2, a metal hammer body 4, and a striking cover 1, wherein the bottom surface of the elastic bowl body 2 is a plane provided with a central circular hole, and a gap between the central circular hole and the edge of the elastic bowl body 2 The flat surface is used for installation, and it is pasted on the car glass by a strong dose of adhesive. The top surface is a concave plane, and a central hole is also provided on the concave plane. Shaped cylinder 3, the taper of the tapered cylinder 3 matches the taper of the tapered hole, the tapered hole directly transitions to the inner cavity of the tapered cylinder, the tapered cylinder 3 is used to fix the metal hammer body 4, in order to fix it more firmly and reliably, the metal The hammer body 4 is pasted in the coni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com