Device for measuring volume change of at least one textile fiber band

A technology of textile fiber and volume change, which is applied in the field of equipment devices, and can solve the problems of not considering the geographical area and the reduction of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

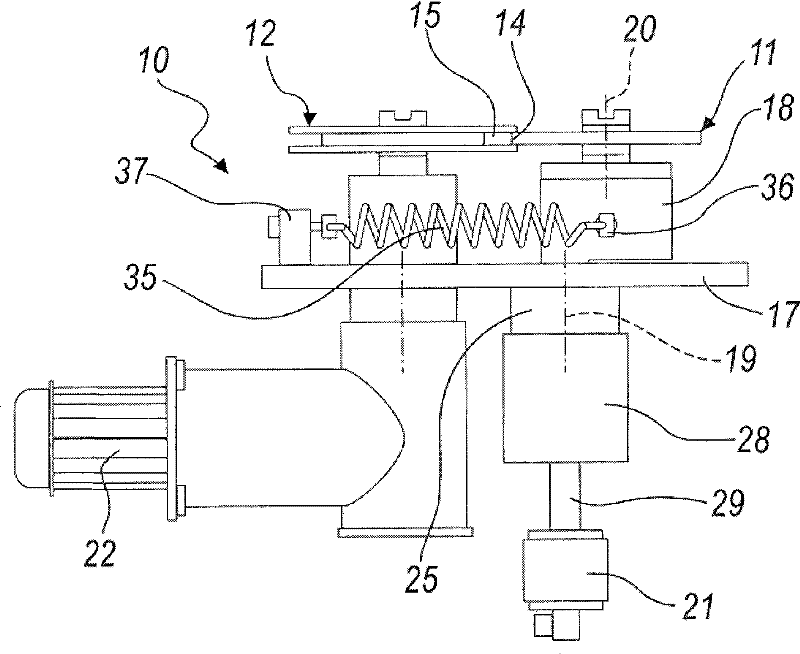

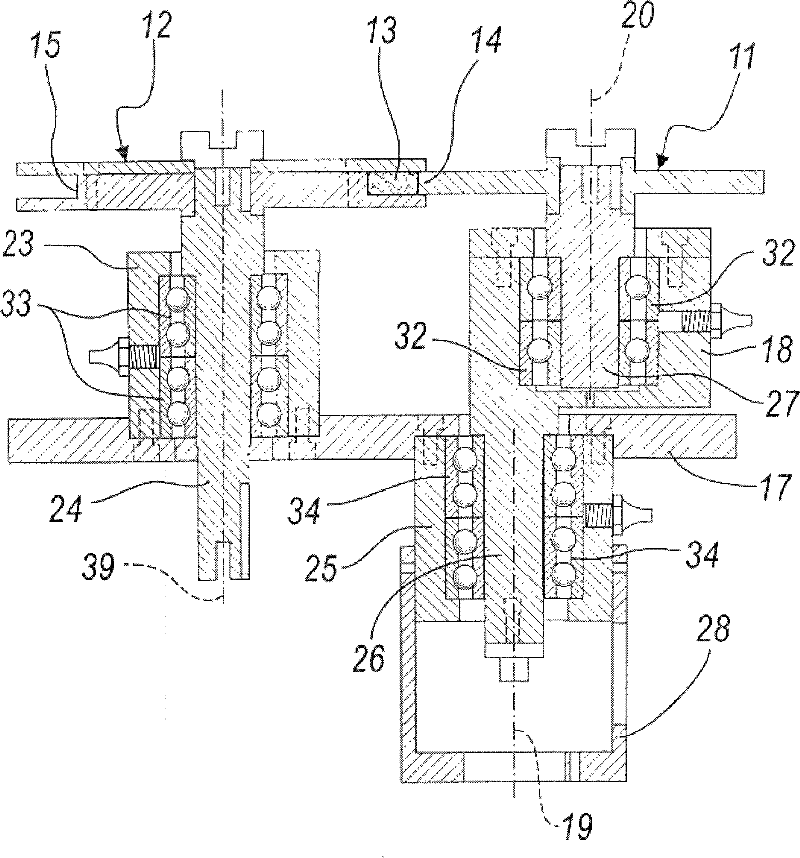

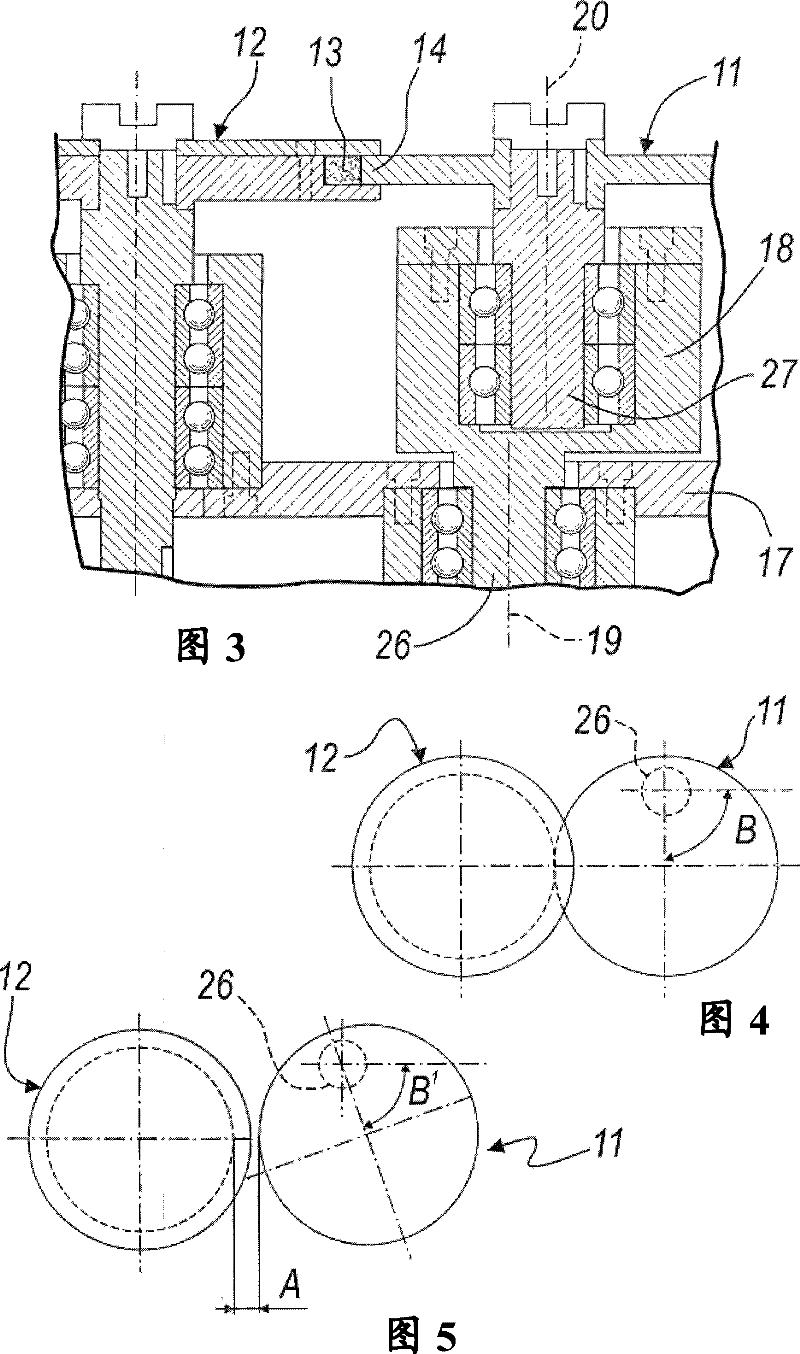

[0030] With reference to the aforementioned figures, a device for measuring the volume change of at least one strip of textile fibers according to the invention is indicated generally by the reference numeral 10 .

[0031] This device 10 comprises a first movable wheel 11 and a second fixed wheel 12 with parallel axles and a variable wheel base, between which at least one textile fiber belt 13 is pulled in a slidable manner .

[0032] The first wheel 11 of these wheels is adapted to fit in the annular groove 15 of the second wheel 12 with its circumferential ring 14 .

[0033] The wheels 11 , 12 are pressed against each other by elastic means (described in detail below) to allow the movement of the first free wheel 11 away from / towards the second wheel 12 depending on the instantaneous section of at least one strap 13 passing through the groove 15 .

[0034] In practice, the belt 13 consists of one or more converging belts pressed by the circumferential ring 14 of the first w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com