Method for determining in-situ gas volume recovery of marine shale, device thereof and system

A shale and in-situ technology, applied in the field of devices and systems, and in-situ gas volume recovery determination methods for marine shale, can solve problems such as existing errors, large errors, and doubts about the accuracy of porosity and gas saturation, etc. To achieve the effect of enriching scientific significance, avoiding uncertainty, and good industrial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

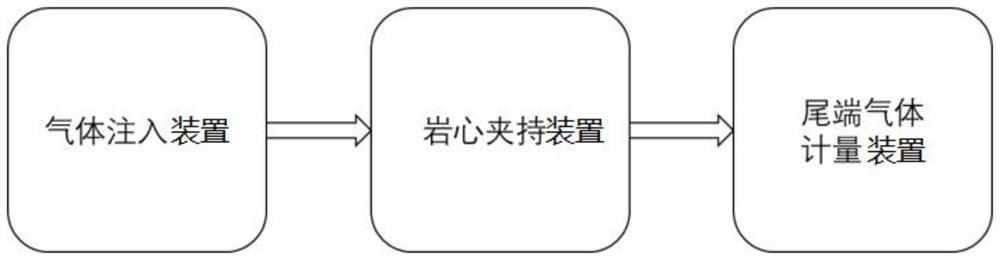

[0081] According to one embodiment of the present invention, the detailed process of in-situ total gas content measurement of marine shale is as follows:

[0082] 1. Prepare the column sample and dry it; 2. Put it into the core holder and vacuumize; 3. Inject the gas of the corresponding pressure into the reference cylinder; 4. Adjust the temperature and pressure conditions of the core holder and the back pressure valve to the actual formation 5. Open the valve and inject gas into the core from the reference cylinder; 6. Balance the pressure at both ends of the core holder to the corresponding value by controlling the stop valve and pressure regulating valve; 7. Read the cumulative flow rate of the gas metering device at the tail end; 8. Calculate the total gas content of shale according to the principle of material conservation.

[0083] Wherein, the formula for calculating the total gas content of shale samples in this invention is:

[0084] V=V 注 -V 管 -V 尾

[0085] V ...

Embodiment

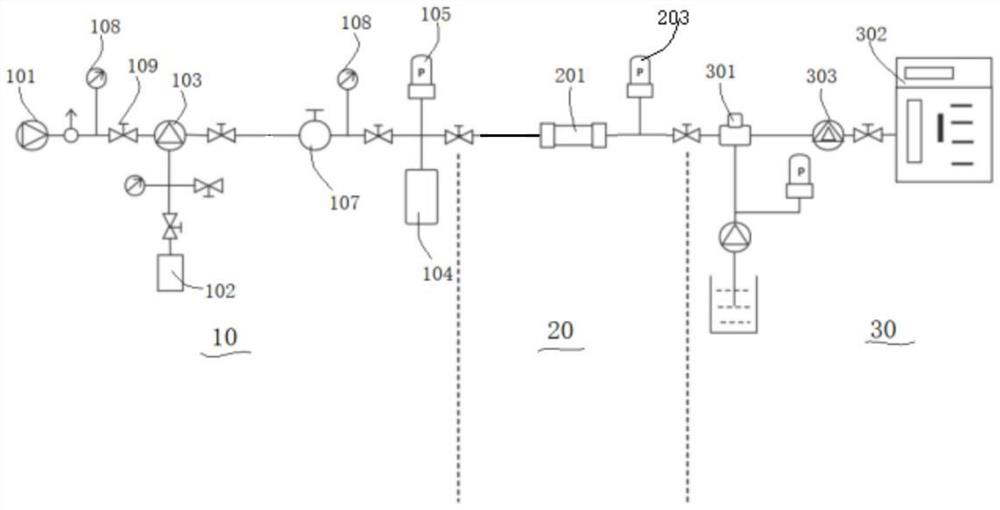

[0096] Using the above as image 3 The device system shown in the figure measures the gas content of shale, and uses the shale in-situ adsorption gas measurement device to measure the adsorption gas capacity, the details are as follows:

[0097] 1. Take a shale sample from Longmaxi Formation in Well W1, and establish a geological model according to the in-situ geological conditions of the sample: the formation temperature is 120°C, the formation pressure is 87.5MPa, and the fluid pressure is 60MPa;

[0098] 2. Prepare a standard column sample of 2.5cm*5cm, wire cut, grind both ends, and dry at 105°C for 24 hours for the total gas content test;

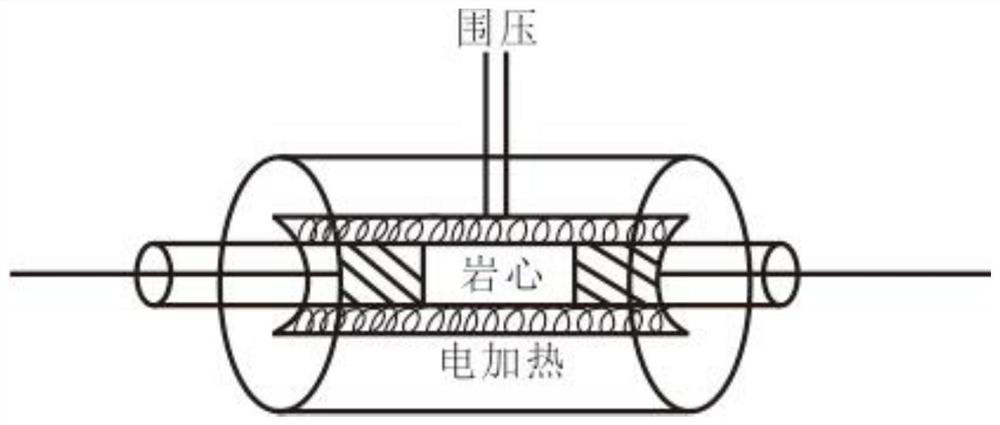

[0099] 3. Put the column sample into the core holder 201, and vacuumize the shale in-situ gas content testing device for 1 hour;

[0100] 4. Inject 100MPa of high-purity methane into the reference cylinder 104;

[0101] 5. Set the temperature and pressure conditions of the core holder 201 as: 120°C and 87.5MPa, and set the pressure o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com