Method for separating liposome-heavy metal compound

A liposome and heavy metal technology, applied in the field of environmental protection pollution treatment, can solve the problems of inability to separate liposome-heavy metal complexes from free heavy metal ions, high instrument cost, long centrifugation time, etc., and achieves significant environmental advantages and Economic advantages, low disposal costs, high recovery rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

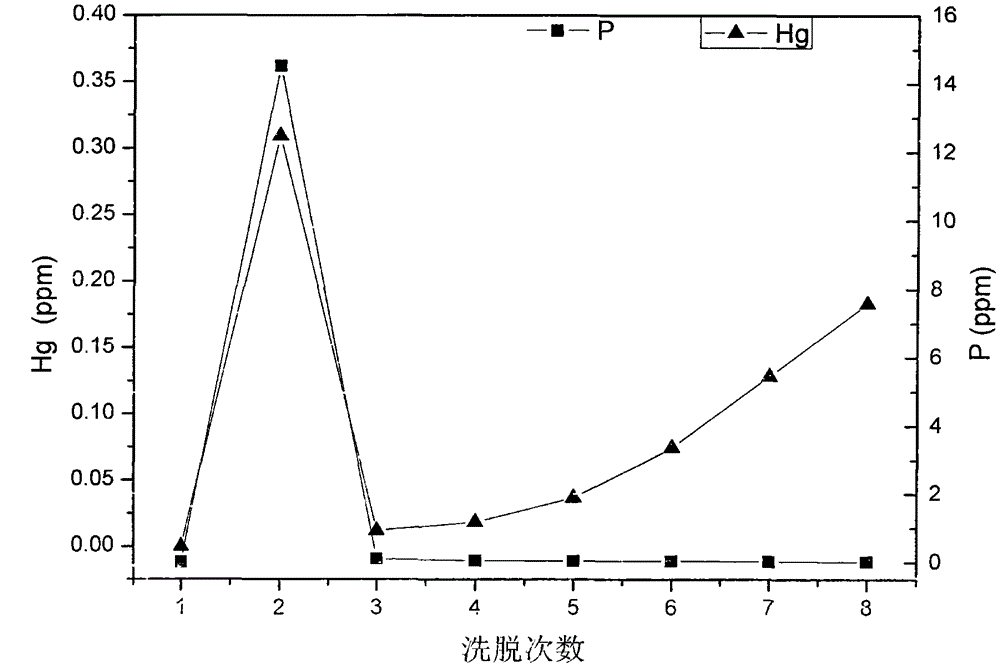

[0030] Embodiment 1: the separation of liposome-mercury complex and free mercury ion

[0031] Liposomes are prepared by solvent evaporation method. Weigh 100mg of ePC, 40mg of cholesterol and 10mg of DPPG solid in a 100mL round bottom flask, dissolve in a mixture of 5mL of chloroform / methanol solution, and place the round bottom flask on a rotary evaporator for evaporation in a water bath Solvent, placed in a vacuum oven to dry for at least 1 hour. Add 5-10mL Tris-HCl buffer solution for hydration until all the lipids are completely detached from the bottle wall to form a uniform milky white suspension without obvious particles. The liposome suspension was passed 21 times through a polycarbonate membrane with a pore size of 800 nm. The concentration of the mercury metal ion stock solution is 500mg / L, take 0.1mL metal ion stock solution, add 0.4mL liposome suspension, and place the resulting mixed solution in a constant temperature shaking box at 25±2°C for 12 hours in the dar...

Embodiment 2

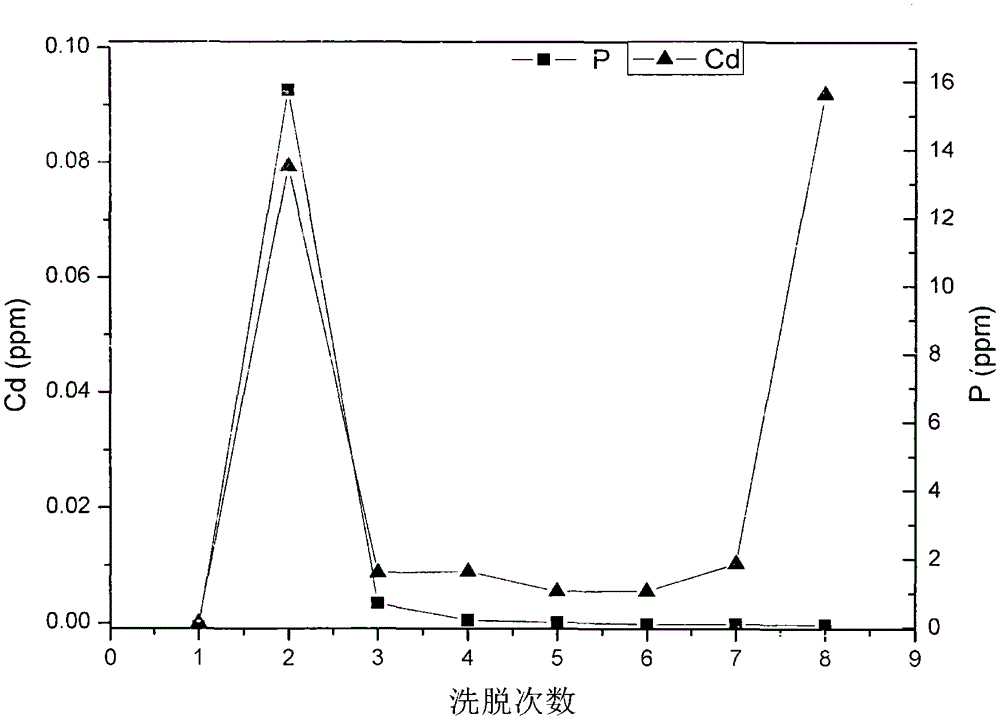

[0036] Embodiment 2: the separation of liposome-cadmium complex and free cadmium ion

[0037] The difference from Example 1 is that liposomes are used to adsorb cadmium ions, and this method is used to separate liposome-cadmium complexes from free cadmium ions.

Embodiment 3

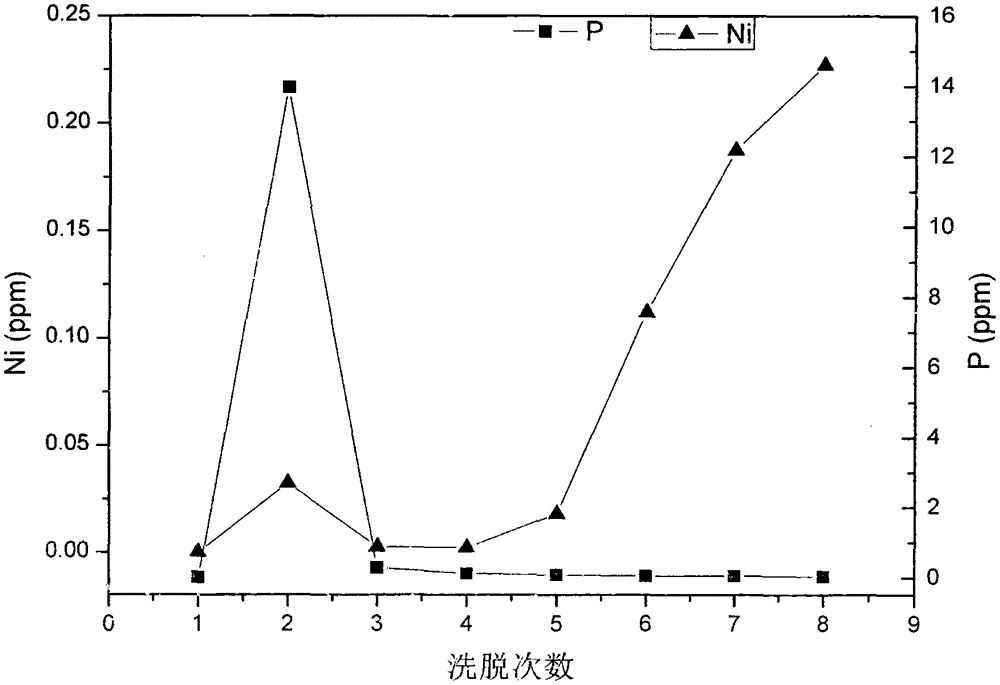

[0038] Embodiment 3: the separation of liposome-nickel complex and free nickel ion

[0039] The difference from Example 1 is that liposomes are used to adsorb nickel ions, and this method is used to separate liposome-nickel complexes from free nickel ions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com