A real shale gas adsorption prediction method based on molecular simulation

A technology of molecular simulation and prediction method, which is applied in the direction of material absorption weighing, specific gravity measurement, and material analysis, and can solve the problem of large gap between adsorption amount and experimental value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

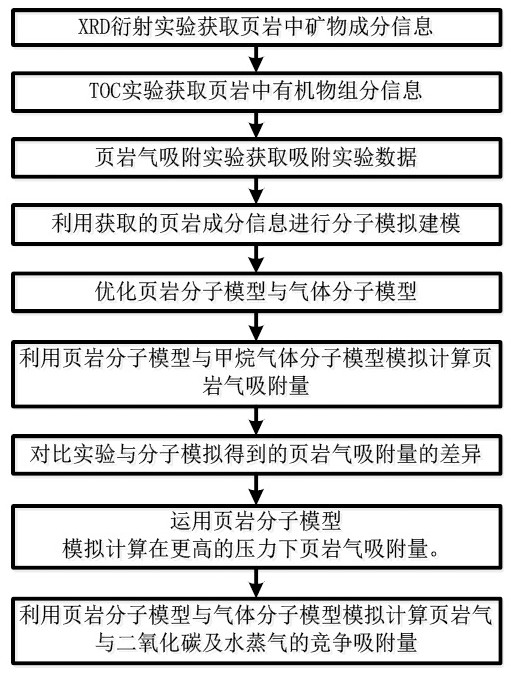

[0119] Such as figure 1 As shown in , a real shale gas adsorption prediction method based on molecular simulation includes the following steps:

[0120] S1. Obtain mineral composition information in shale through XRD diffraction experiment, including the following sub-steps:

[0121] S101, powdering the shale sample, including the following processing methods:

[0122] (1) The oil-bearing shale samples should be washed and processed to a fluorescence level below level 4;

[0123] (2) Dry the shale samples at a temperature lower than 60°C, cool to room temperature, and pulverize them for use;

[0124] (3) Grind the crushed rock samples until the total particle size is less than 40 μm or there is no graininess when kneaded by fingers.

[0125] S102. Extracting the clay minerals in the rock sample and making slices, including the following processing methods:

[0126] (1) Put the powdered sample in a 40ml tall beaker, add 10ml of distilled water to soak, and use a CQX-25-06 (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| face spacing | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| bond angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com