Two-chip type f Theta lens of microcomputer electric laser scanning device

A technology of laser scanning device and micro-electromechanical mirror, which is applied in the field of two-piece fθ lens

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

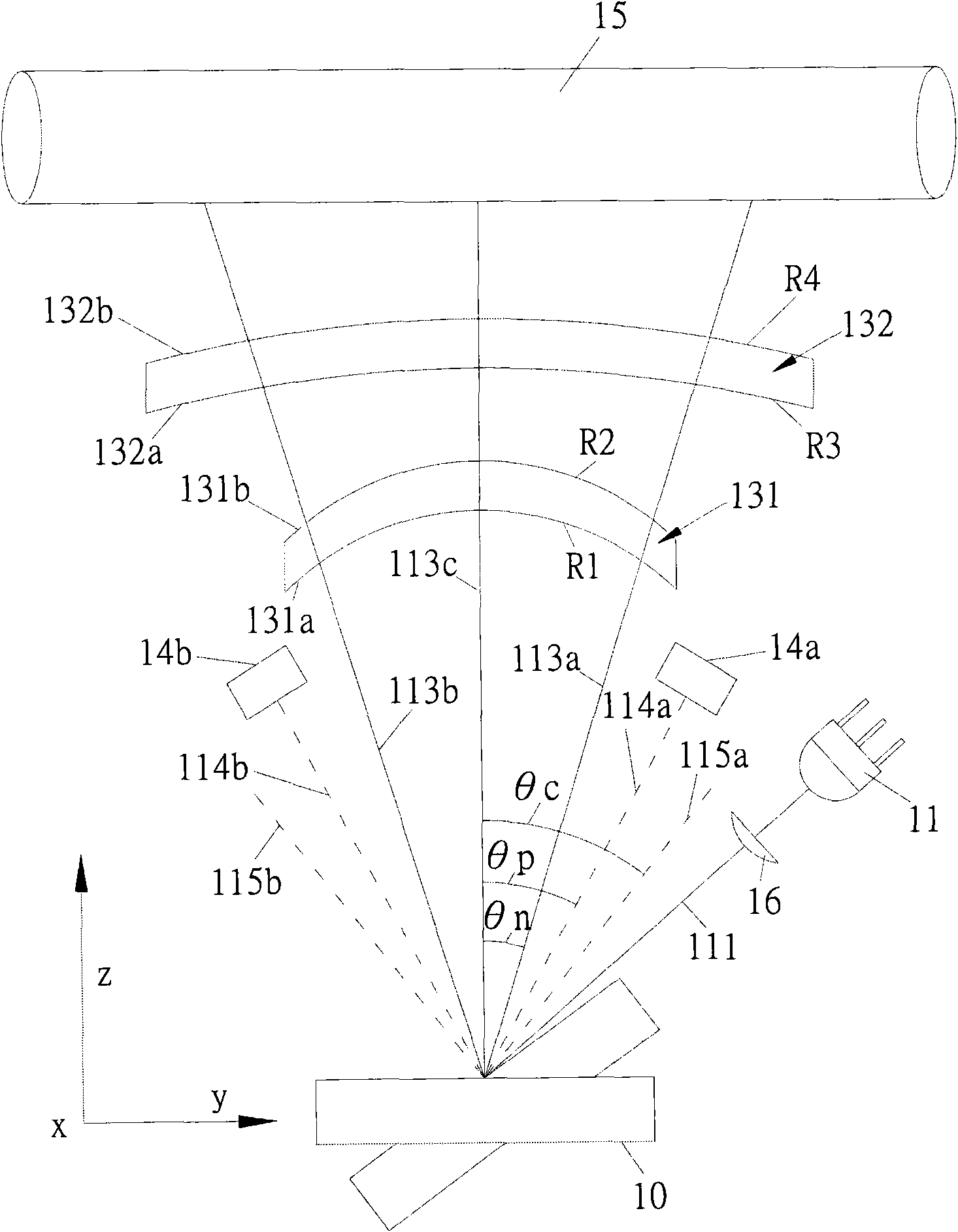

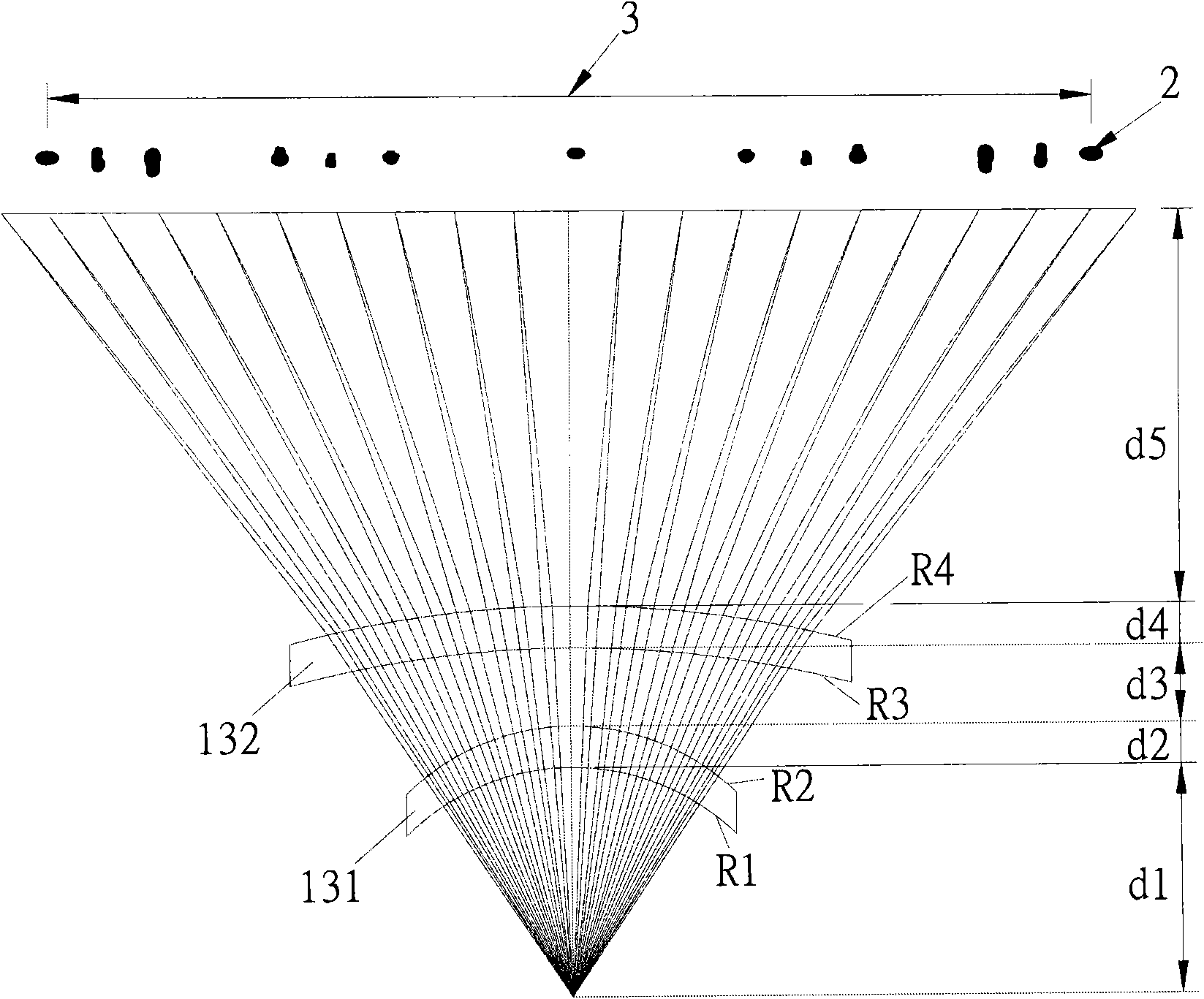

[0107] The first lens and a second lens of the two-piece type fθ lens of the present embodiment are both crescent-shaped lenses with a concave surface on the side of the micro-electromechanical mirror. The four optical surfaces are aspherical surfaces, and formula (2) is used to design aspheric surface formulas; the second optical surface of the first lens and the third optical surface of the second lens are aspherical surfaces, and formula (2) is used to design aspheric surface formulas . Its optical characteristics and aspheric parameters are shown in Table 1 and Table 2 below.

[0108] Table 1. The fθ optical characteristics of the first embodiment

[0109]

[0110] Table two, the optical surface aspherical parameters of the first embodiment

[0111]

[0112] The optical path diagram of the optical surface of the two-piece fθ lens formed through this is as follows Figure 5 Shown is the optical path diagram of the first preferred embodiment of the present invention...

no. 2 example

[0116] The first lens and a second lens of the two-piece type fθ lens in this embodiment are both crescent-shaped lenses with a concave surface on the side of the micro-electromechanical mirror. The first optical surface of the first lens is an aspherical surface, and the use formula (3) design for the aspheric surface formula; be the aspherical surface at the second optical surface of the first eyeglass and the third learning surface of the second eyeglass, use formula (2) to be the aspheric surface formula design; the 4th learning surface of the second eyeglass is for the sphere. Its optical characteristics and aspheric parameters are shown in Table 4 and Table 5 below.

[0117] Table 4. The fθ optical characteristics of the second embodiment

[0118] fs=155.0

optical surface

Radius of curvature (mm)

dThickness (mm)

(optical surface)

(curvature)

(thickness)

(refraction index)

MEMS reflective...

no. 3 example

[0125] The first lens and a second lens of the two-piece type fθ lens of the present embodiment are all crescent-shaped and the lens whose concave surface is on the side of the micro-electromechanical mirror is formed, and the first optical surface of the first lens and the fourth lens of the second lens are The optical surface is a spherical surface in the sub-scanning direction; the second optical surface of the first eyeglass and the third optical surface of the second eyeglass are aspherical surfaces, and the formula (2) is used to design the aspheric surface formula; the first optical surface of the first eyeglass and the third optical surface of the second eyeglass The fourth optical surface of the second lens is an aspheric surface in the main scanning direction, and the formula (3) is used to design the aspheric surface formula. Its optical characteristics and aspheric parameters are shown in Table 7 and Table 8 below.

[0126] Table seven, fθ optical characteristics o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com