Multibeam straight-line laser scanning device

A scanning device and multi-beam technology, applied in the direction of optics, optical components, lenses, etc., can solve the problems of increased rotation noise, complicated structure and configuration, and long time-consuming polygon mirrors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]In order to make the present invention more definite and detailed, preferred embodiment is cited hereby and cooperates following figure, structure and technical characterictic thereof of the present invention are described in detail as follows:

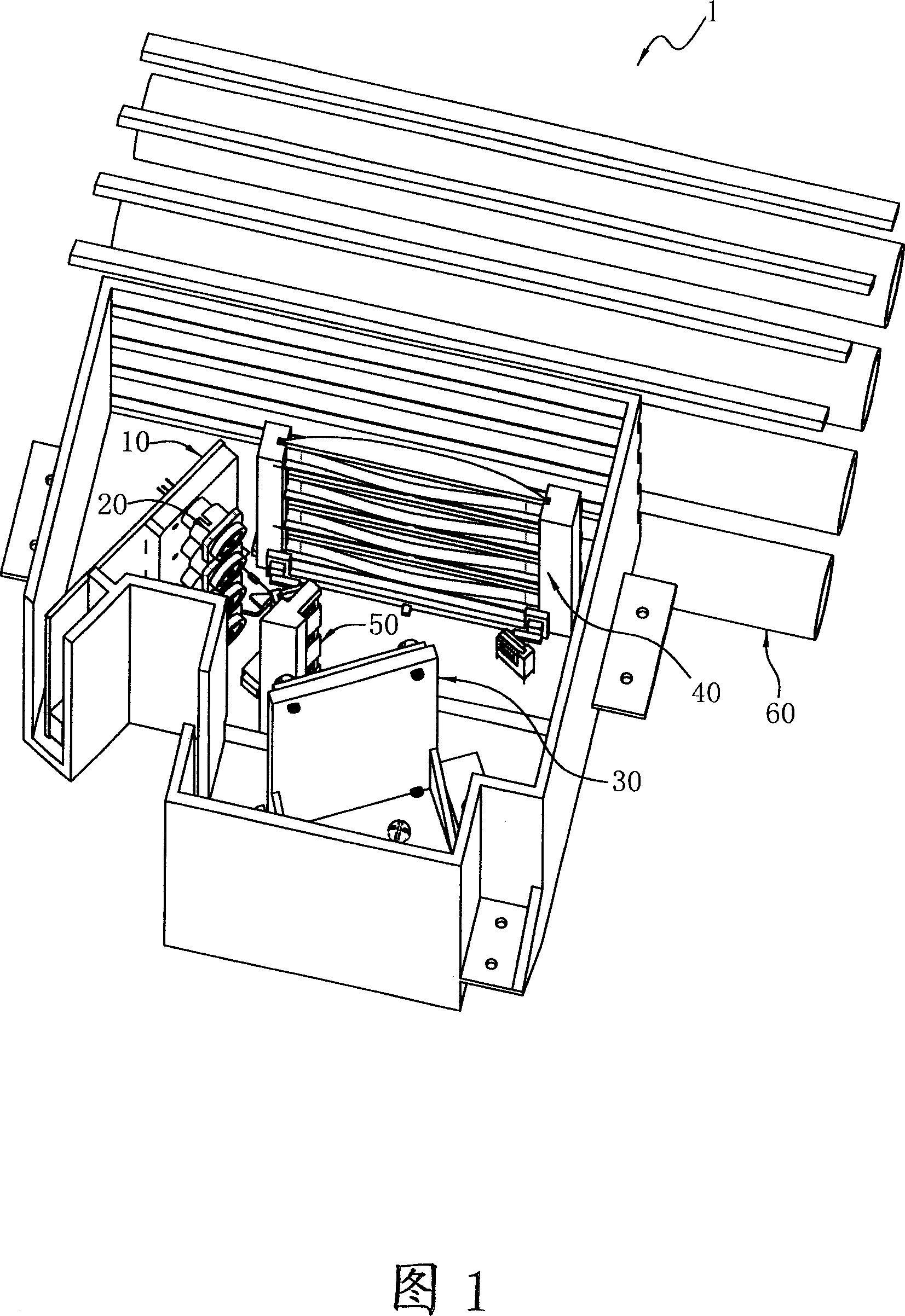

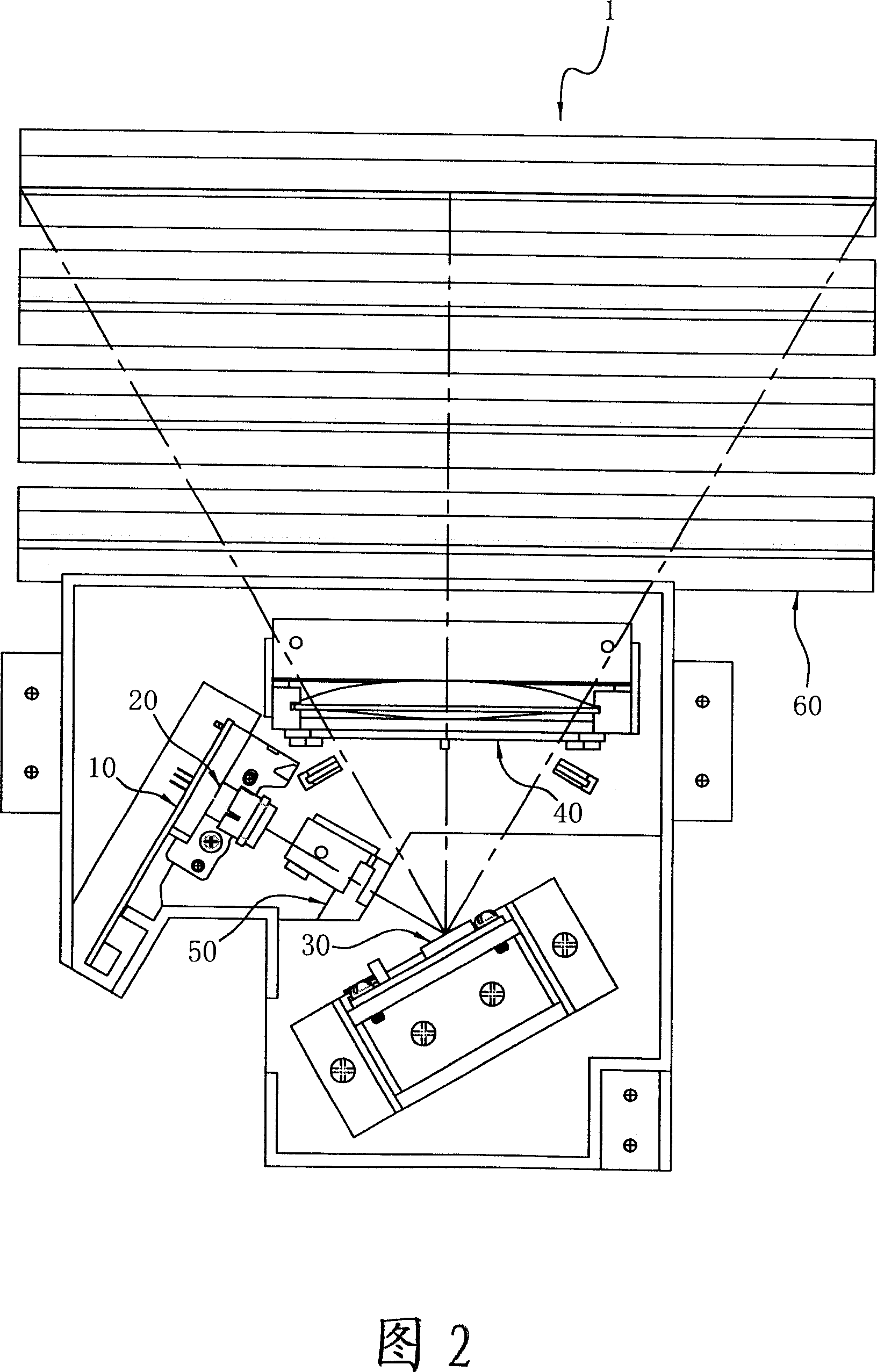

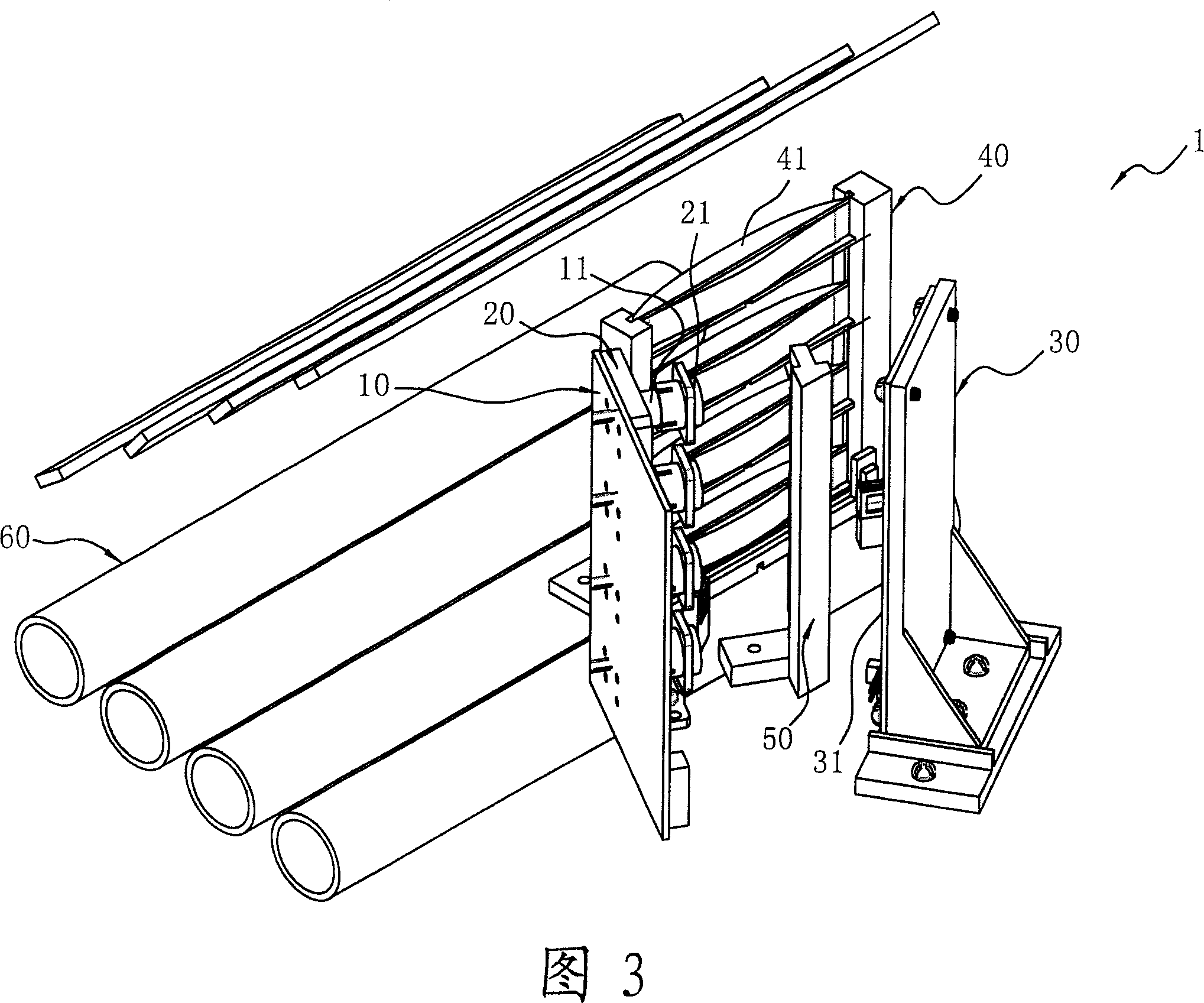

[0029] Referring to Fig. 1-7, it is a three-dimensional schematic diagram of a preferred embodiment of the multi-beam in-line laser scanning unit LSU (Multi-Beam Laser Scanning Unit) of the present invention, hereby the laser scanning device 1 with four beams For example, the multi-beam in-line LSU1 of the present invention includes a semiconductor laser group 10, a collimating mirror group 20, a MEMS oscillatory mirror group 30, and a linear scanning mirror group 40, wherein , the semiconductor laser group 10 can be made up of four groups of single-beam semiconductor laser LD (single-beam Laser Diode) 11, each single-beam semiconductor laser 11 emits a laser beam as shown in Figure 9 (A), or use Two groups of dual-beam semicond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com