Sloping plate sedimentation tank for lateral rotational flow sludge discharge

A technology of inclined plate sedimentation and flow discharge, applied in the field of sedimentation tanks, can solve problems such as poor sludge discharge effect, and achieve the effect of slow settling speed, enhanced sludge discharge effect, and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

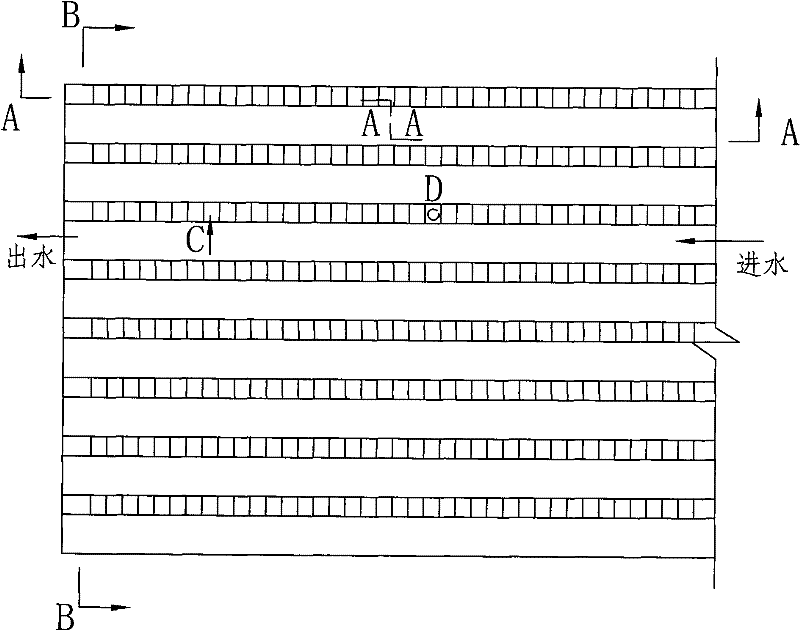

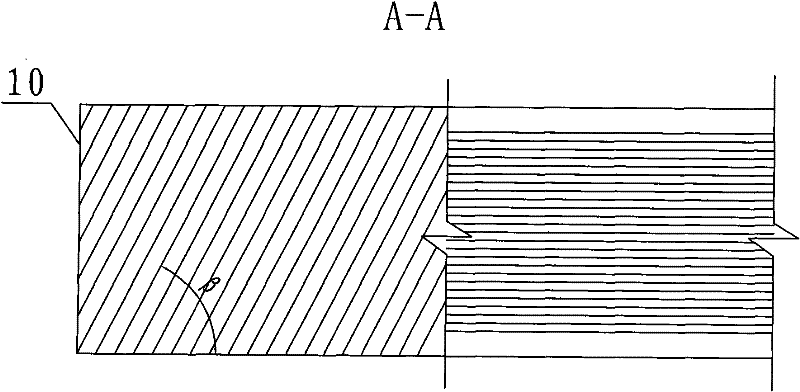

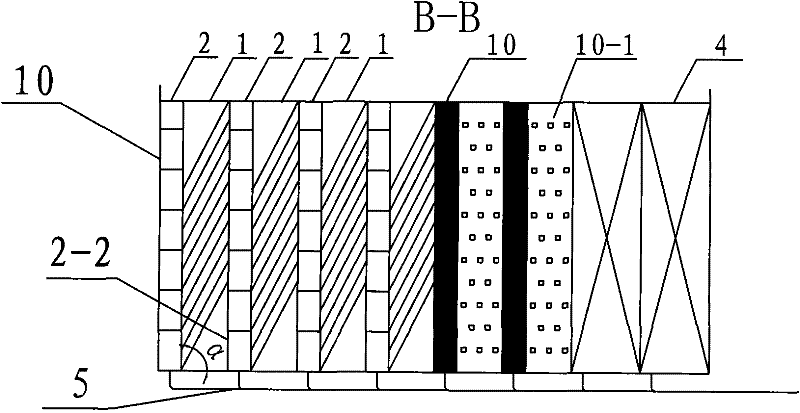

[0008] Specific implementation mode one: as Figure 1~6 As shown, the sloping plate sedimentation tank of the side swirl mud discharge described in this embodiment includes a tank body 10, a plurality of sloping plate sedimentation units 1 and a plurality of sloping plate sedimentation units 2, and a plurality of sloping plate sedimentation units 1 and multiple sloping plate sedimentation units. Two inclined plate mud guide units 2 are arranged in parallel in the tank body 10, and each inclined plate sedimentation unit 1 includes several sedimentation plates 1-1, and the several sedimentation plates 1-1 are inclined in parallel at a certain interval from top to bottom. The inclination angle α of each sedimentation plate 1-1 relative to the horizontal plane is 50°~70°, and each sedimentation plate 1-1 is perpendicular to the two sides of the pool body 10; The inclined plate mud guide unit 2 includes several mud guide plates 2-1 and baffle plates 2-2, and several mud guide plate...

specific Embodiment approach 2

[0009] Specific implementation mode two: as Figure 1~6 As shown, the distance between two adjacent precipitation plates 1 - 1 in this embodiment is 20-450 mm. The turbidity of the effluent from the sedimentation tank can reach 0.8-3NTU. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: as Figure 1~6 As shown, the distance between two adjacent mud deflectors 2 - 1 in this embodiment is 5-150 mm. The turbidity of the effluent from the sedimentation tank can reach 0.8-2NTU. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com