Method for movably collecting, conveying, dedusting and desulfurizing dust of coke oven coke guide

A technology for collecting fume and coke trapping car, which is applied in the field of separation by physical or chemical methods, can solve the problems of large resistance loss, inconvenient operation, complicated laying, etc., achieves small resistance loss, simple and practical operation, and enhances the effect of dust removal, desulfurization and purification Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

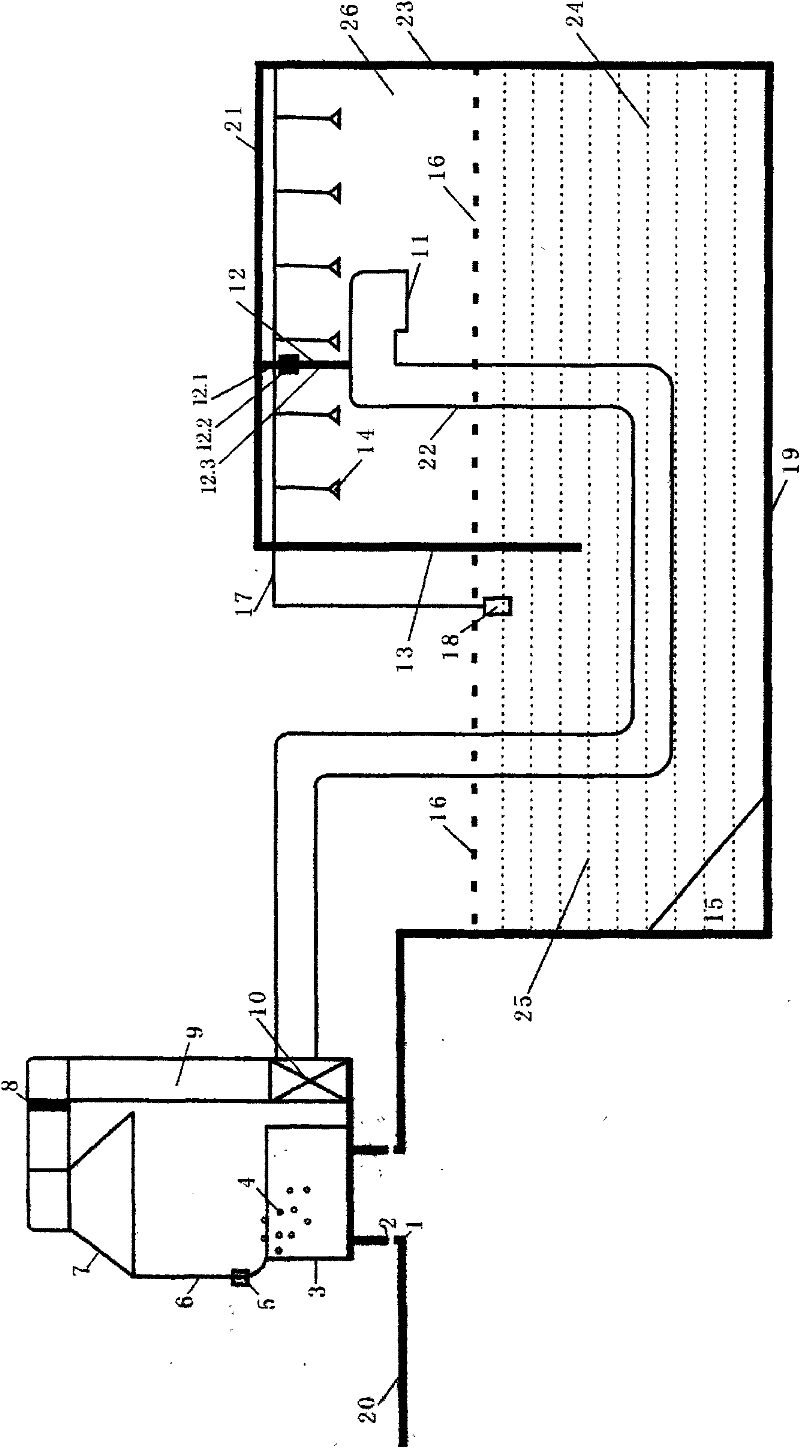

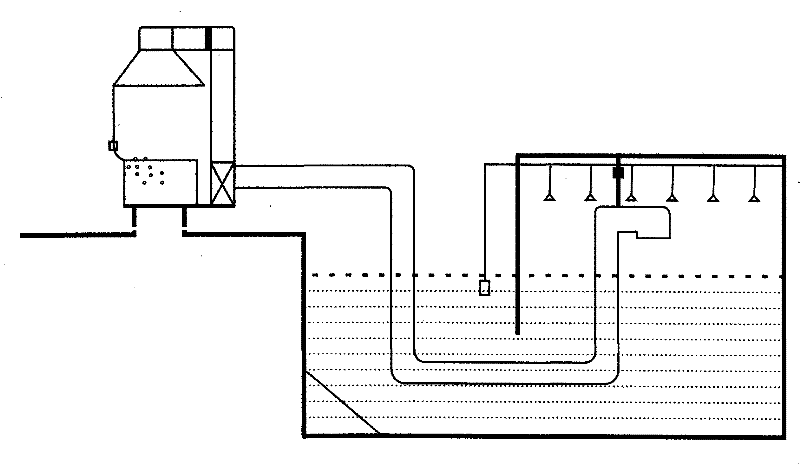

[0031] The method of collecting, transporting, dust removal and desulfurization of coke truck smoke and dust in this embodiment is as follows:

[0032] 1) see figure 1 , the movable bolt 5 and the support rod 6 are set on the coke-stopping car 3 to fix and support the dust-absorbing hood 7, and are connected with the flue 9 through the movable joint 8, and the smoke dust generated in the coke-stopping process is passed through the dust-absorbing hood 7 by the induced draft fan 10 After being collected, it enters the inner chamber channel 26 through the U-shaped flue 22 .

[0033] See figure 1 , the dust-laden air flow rushes downward at the dust-laden gas inlet 11 to the liquid surface 16 at high speed, arouses waves and foams and contacts and mixes with them, producing dust removal, desulfurization and purification effects.

[0034] At the same time, the dust-laden airflow is forced to turn after meeting the liquid surface 16, and the coarse particles are captured and dropp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com