Manufacturing method of aluminum or aluminum-alloy seamless pipe

A manufacturing method, aluminum alloy technology, applied in the direction of metal rolling, etc., can solve the problems of energy waste, large consumption of mold tooling, low production efficiency, etc., and achieve the effects of reducing production costs, improving production efficiency, and simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0028] In order to make the above objectives, features and advantages of the present invention more obvious and understandable, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

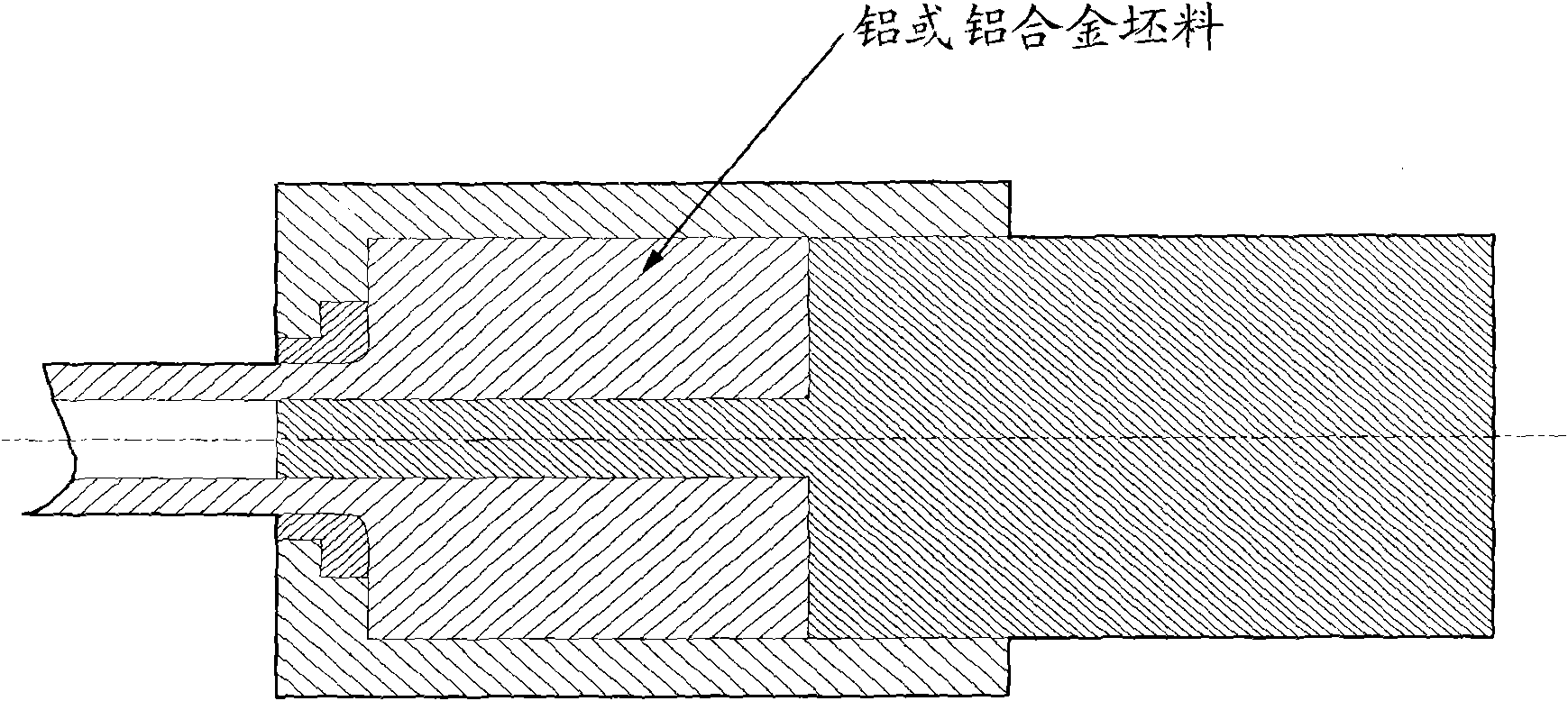

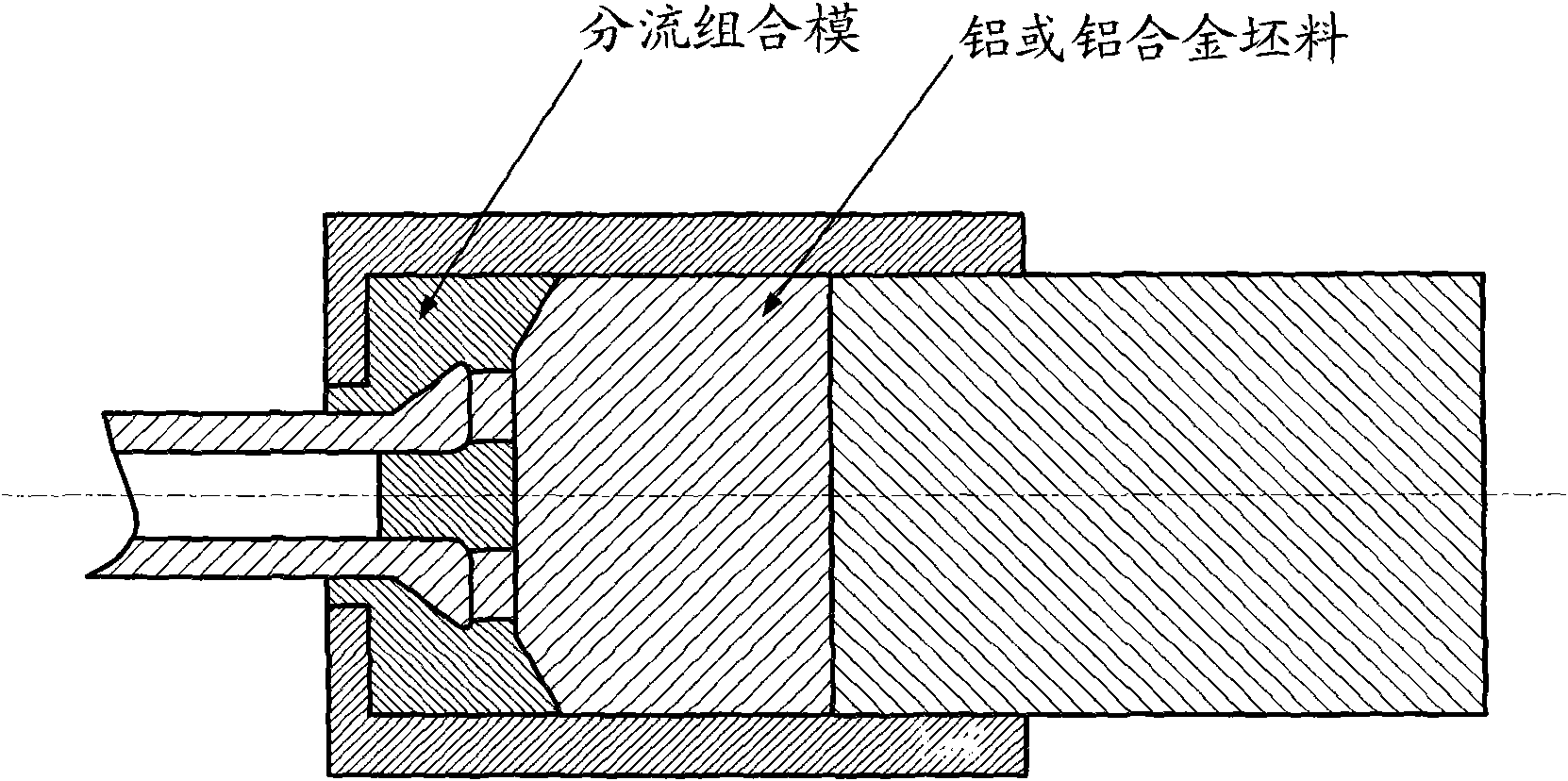

[0029] In the first embodiment of the present invention, an aluminum or aluminum alloy cast straight pipe is selected as the billet for rolling used in the embodiment of the aluminum or aluminum alloy seamless pipe manufacturing method of the present invention, wherein the aluminum or aluminum alloy cast straight pipe is The weight of a single root is about 20-1000 kg, the outer diameter is about 30-150 mm, and the wall thickness is about 6-40 mm.

[0030] Before rolling the aluminum or aluminum alloy seamless pipe, the opening width of the planetary rolling mill roll, the elevation angle of the press roll base and the rolling pass processing rate are set according to the size of the pre-rolled rolling pipe. Among them, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap