Combination stiffening filling pile

A technology of pouring piles and plain concrete piles, which is applied in the field of geotechnical engineering, can solve the problems of low bending resistance and shear resistance, achieve good economic and environmental benefits, improve the utilization rate of steel materials, and avoid sudden accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

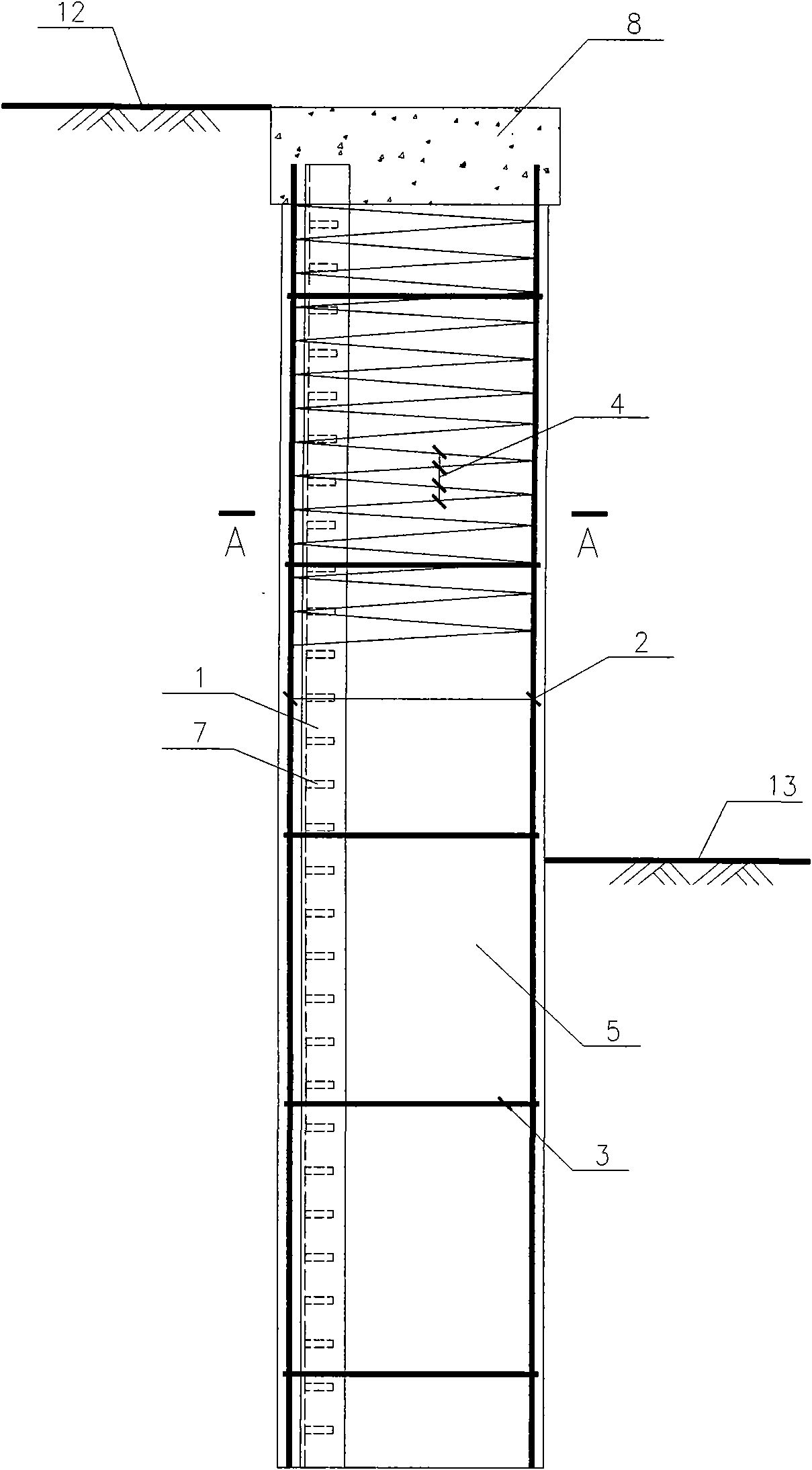

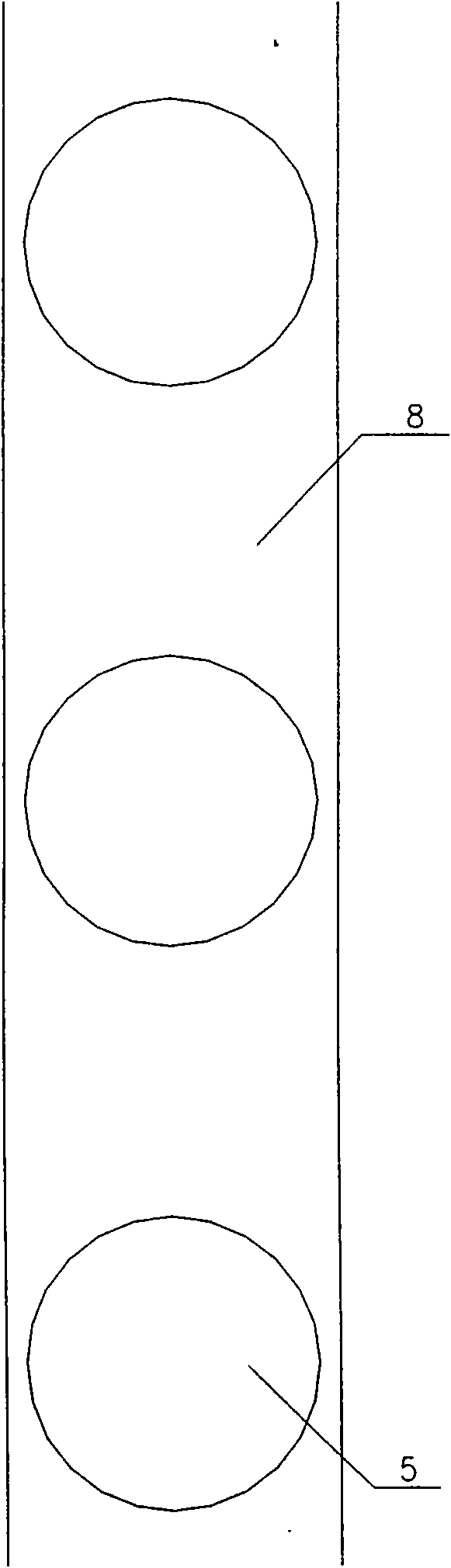

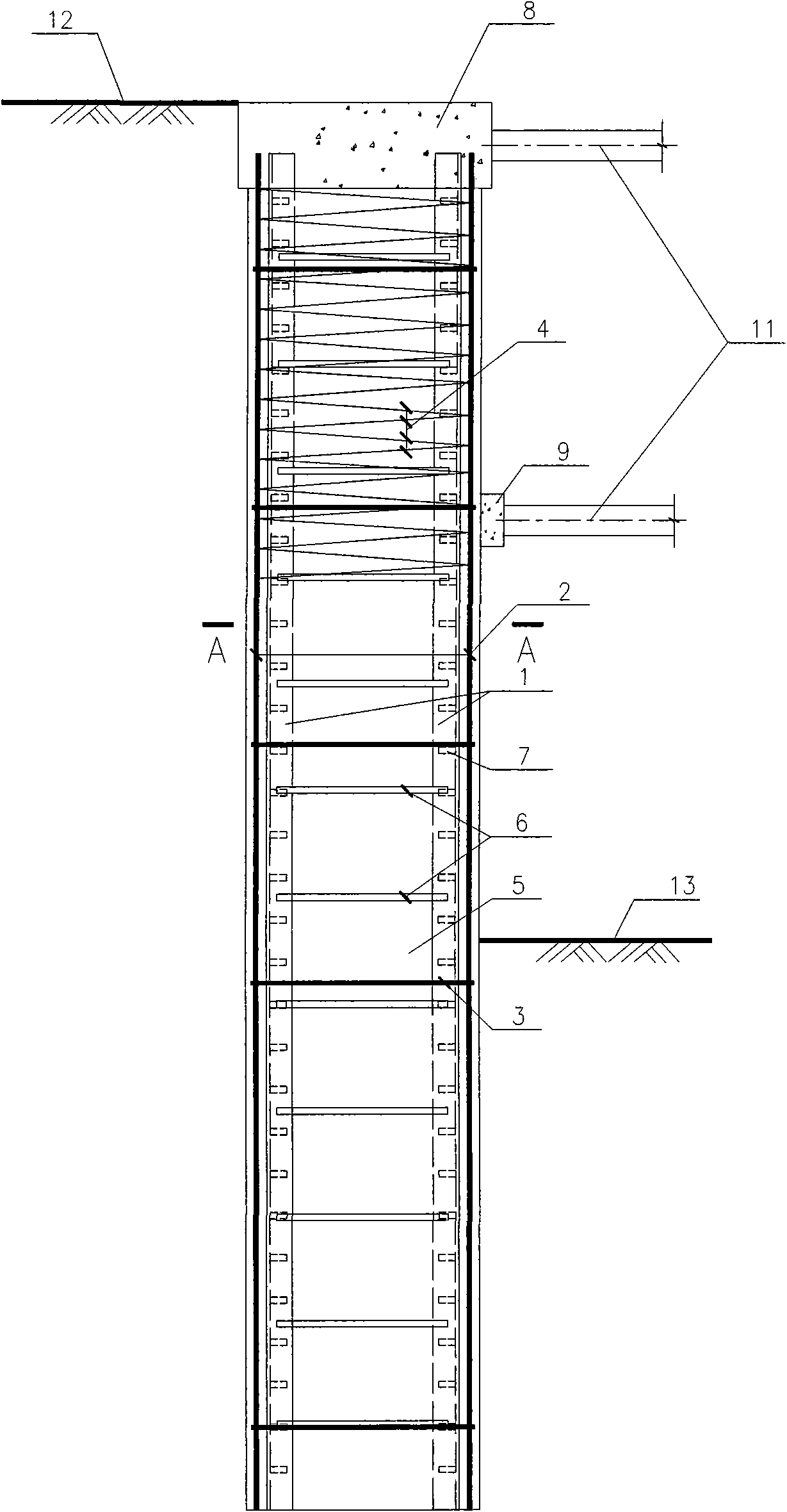

[0041] see figure 1 with Figure 8 , the composite stiffened cast-in-situ pile includes a plain concrete pile body 5, a steel cage and a steel skeleton, and the steel skeleton is coaxial with the plain concrete pile body, and the plain concrete pile body is wrapped with a steel cage and a steel skeleton, and the steel skeleton includes one or two parallel channel steel, see Figure 10 , the reinforcement cage includes stressed longitudinal reinforcement 2 evenly distributed on the circumference, annular reinforcing reinforcement 3 and spiral stirrup 4 surrounding the longitudinal reinforcement;

[0042] The strength of the plain concrete pile body is C20-C30, and different materials can also be selected according to the force of the pile and the diameter of the pile.

[0043] The channel steel model is adjusted according to the calculated bending moment. Various types of ordinary channel steel and light channel steel can be selected, and these steel profiles can also be used...

Embodiment 2

[0050] The profile steel skeleton includes one or two pairs of skeletons composed of two symmetrically arranged channel steels or I-beams, see Figure 7 , Figure 9 with Figure 15 .

[0051] The type of channel steel or I-beam is adjusted according to the calculated bending moment. Various types of ordinary channel steel, light channel steel and I-beam can be selected, and these steel sections can also be used to form a lattice composite section steel.

[0052] Others are with embodiment 1.

Embodiment 3

[0054] see Figure 11 , Figure 13 with Figure 16 , each pair of channel steels or I-beams is radially arranged with horizontal connecting ribs 6 from top to bottom, and the distance between adjacent horizontal connecting ribs 6 is 500-1000 mm.

[0055] When two section steels are symmetrically placed on both sides of the neutral axis of the pile, threaded steel bars or steel plates are used as connecting bars, which are respectively welded to the section steels on both sides to form a lattice-type combined section steel; the vertical distance is 500-1000 mm, according to the groove Adjust the steel layout accordingly.

[0056] Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com