Device and method thereof for constructing a large-sized spherical tank construction platform

A construction platform and spherical tank technology, which is applied in construction, building structure, housing structure support, etc., can solve the problems of small internal space, large workload, waste of construction materials, etc. Small space and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

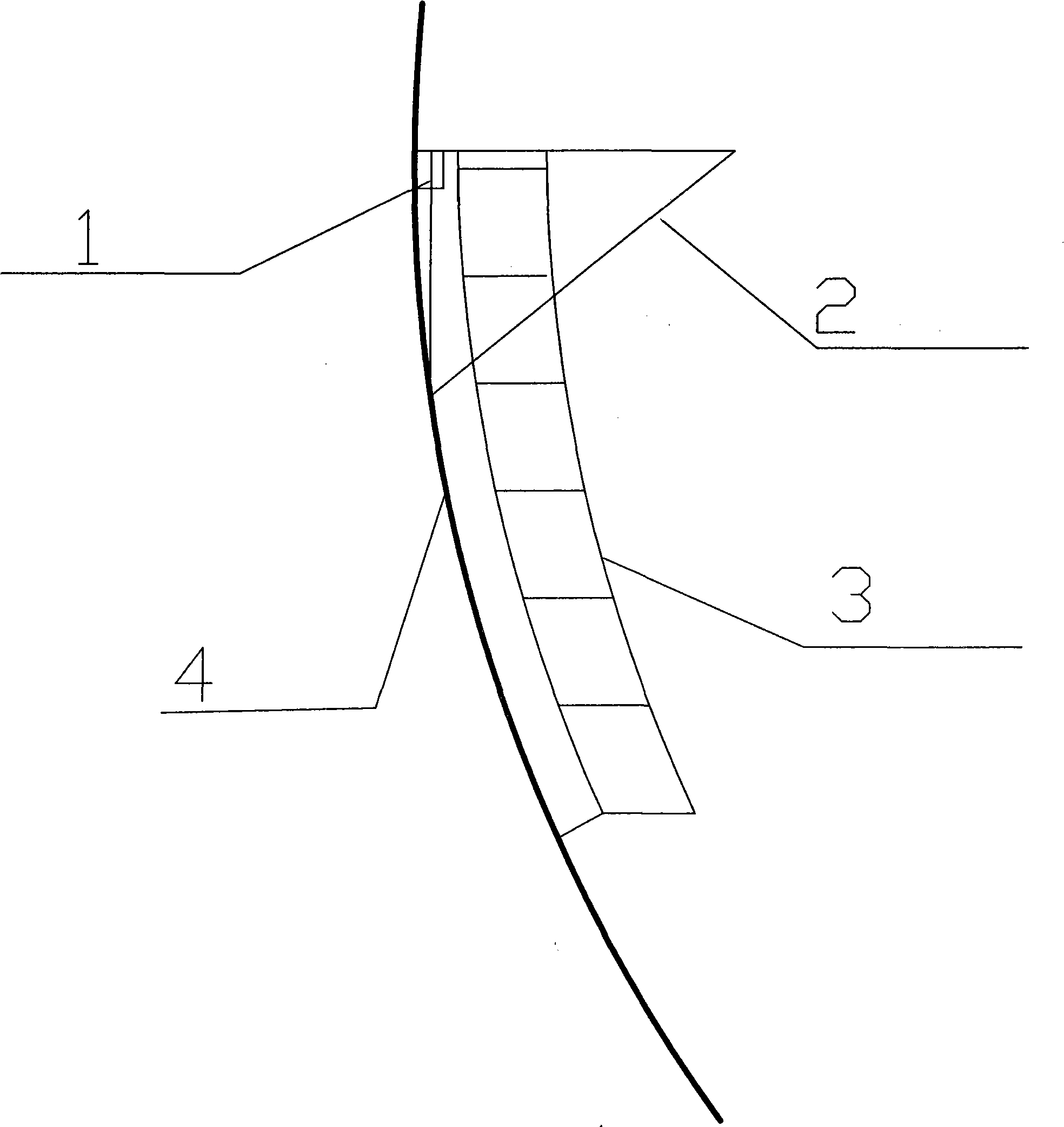

[0020] see figure 1 , a large-scale spherical tank construction platform construction device, which includes a hanging nose 1 arranged on a spherical tank shell plate 4, a triangular support frame 2 is arranged on the hanging nose, one of the right-angled sides is fixed on the hanging nose, and the other right-angled The sides are vertically supported on the shell of the spherical tank, and the arc-shaped ladder 3 vertically arranged with the shell of the spherical tank is connected to the support frame through the hook on the ladder, and a platform plate is laid on the same height of the adjacent ladder. The tripod arc ladder device is easy to disassemble, and the arc ladder can be used repeatedly as long as the inner diameters of the shell plates of the spherical tank are similar. According to actual needs during construction, arc ladders can be built in sections at different heights to lay steel platform slabs, instead of fully covering them from the bottom to the top.

Embodiment 2

[0022] The construction method of the large-scale spherical tank construction platform construction device includes (1) before the spherical shell plate is hoisted, fixing the nose hanger 1 on the spherical tank shell plate 4, fixing the triangular support frame 2 on the hanger nose, one of which is at a right angle One side is fixedly connected to the hanging nose, and the other right-angle side is vertically supported on the shell of the spherical tank; (2) Assemble the shell of the spherical tank, and hang an arc-shaped ladder 3 perpendicular to the shell of the spherical tank on the support frame; (3) Lay the platform plate on the adjacent support frame at the same height; (4) connect the platform plate on the shell plate of the spherical tank to form a complete circle through the aforementioned (1), (2), and (3), and use the same method on the spherical tank shell to form a complete circle. The tank shell plate can build a multi-layer construction work platform, which can ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap