Gas wave refrigerator

A gas wave refrigerator and body technology, applied in refrigerators, refrigeration and liquefaction, compressors, etc., can solve the problems of cooling loss, frictional heat generation, poor sealing effect, etc., to reduce the difficulty of manufacturing and assembly, and reduce friction. Heat generation, sealing effect improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

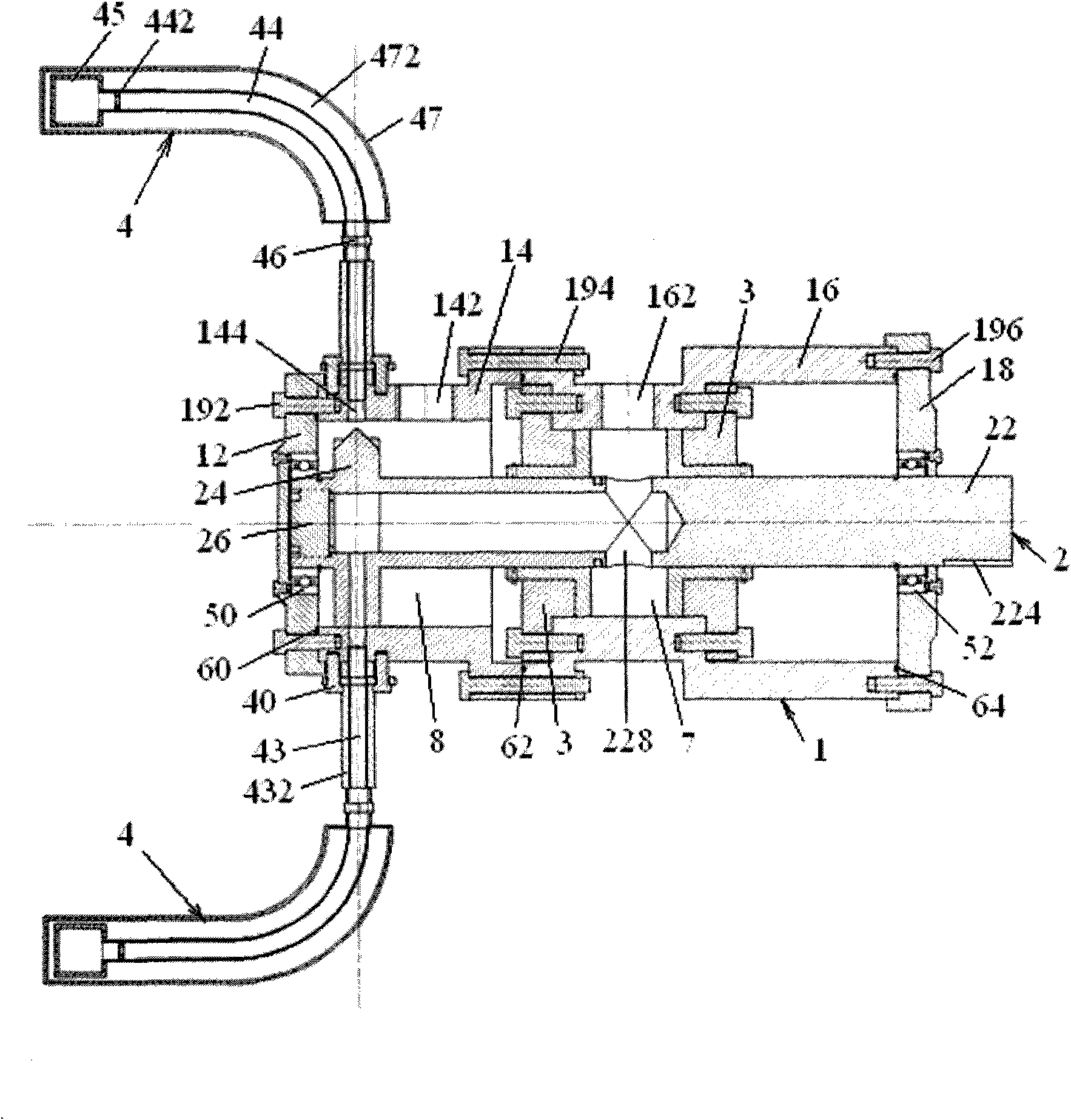

[0018] Please refer to figure 1 As shown, the gas wave refrigerator of the embodiment of the present invention includes a body 1 , a wheel distributor 2 , a sealing structure 3 , a receiving pipe 4 , bearings 50 , 52 and sealing rings 60 , 62 , 64 .

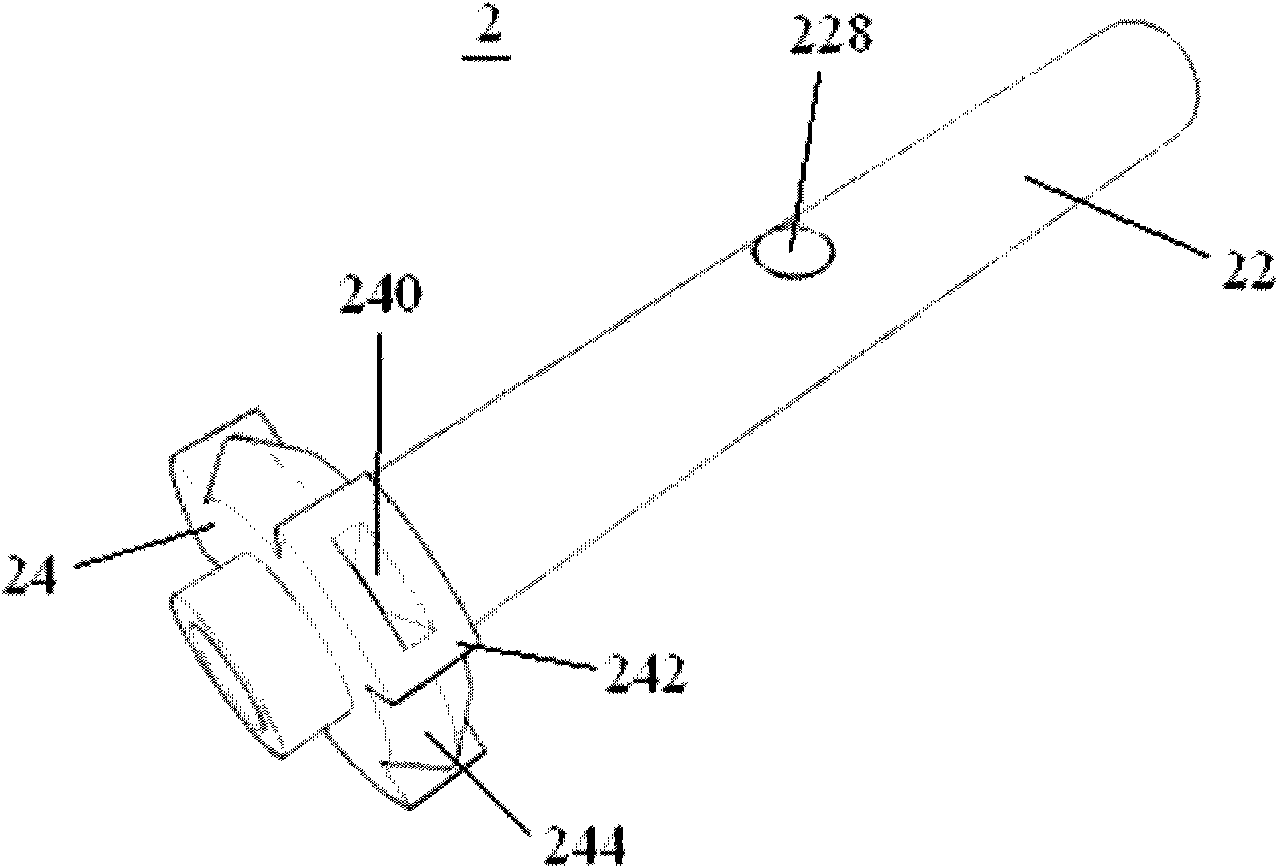

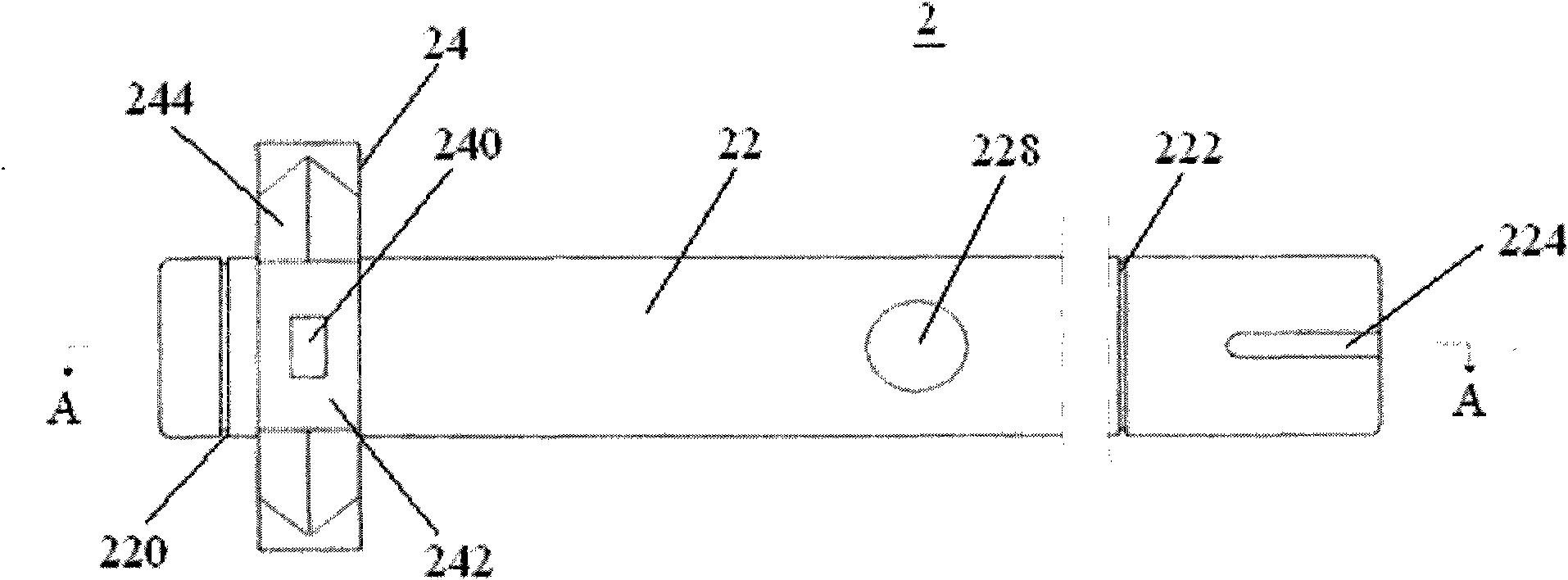

[0019] The body 1 includes a first end cover 12 , a first casing 14 , a second casing 16 and a second end cover 18 . Both the first casing 14 and the second casing 16 are roughly hollow cylinders with open ends, wherein the first casing 14 is provided with a through air outlet 142 and a plurality of holes evenly distributed around the first casing 14. The through receiving pipe interface 144, in this embodiment, the receiving pipe interface 144 is a stepped through hole. The second casing 16 is provided with a thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com