On-line data measuring method for regular polygon measured object based on machine vision and system

A regular polygon, machine vision technology, used in measuring devices, instruments, optical devices, etc., can solve the problems of picture distortion, difficult to obtain equipment, and high error rate, to eliminate asynchronous errors, solve technical bottlenecks, and ensure measurement. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

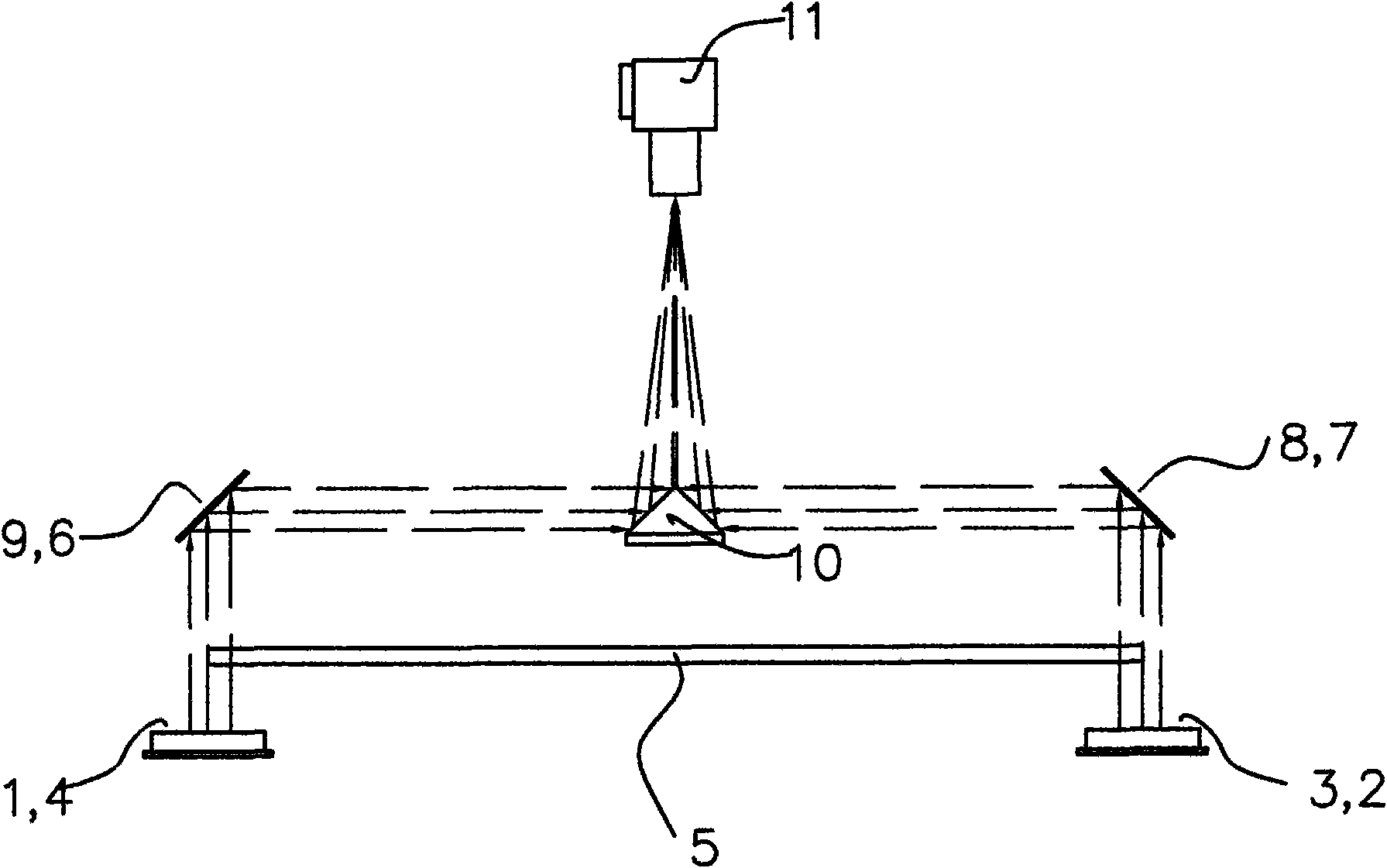

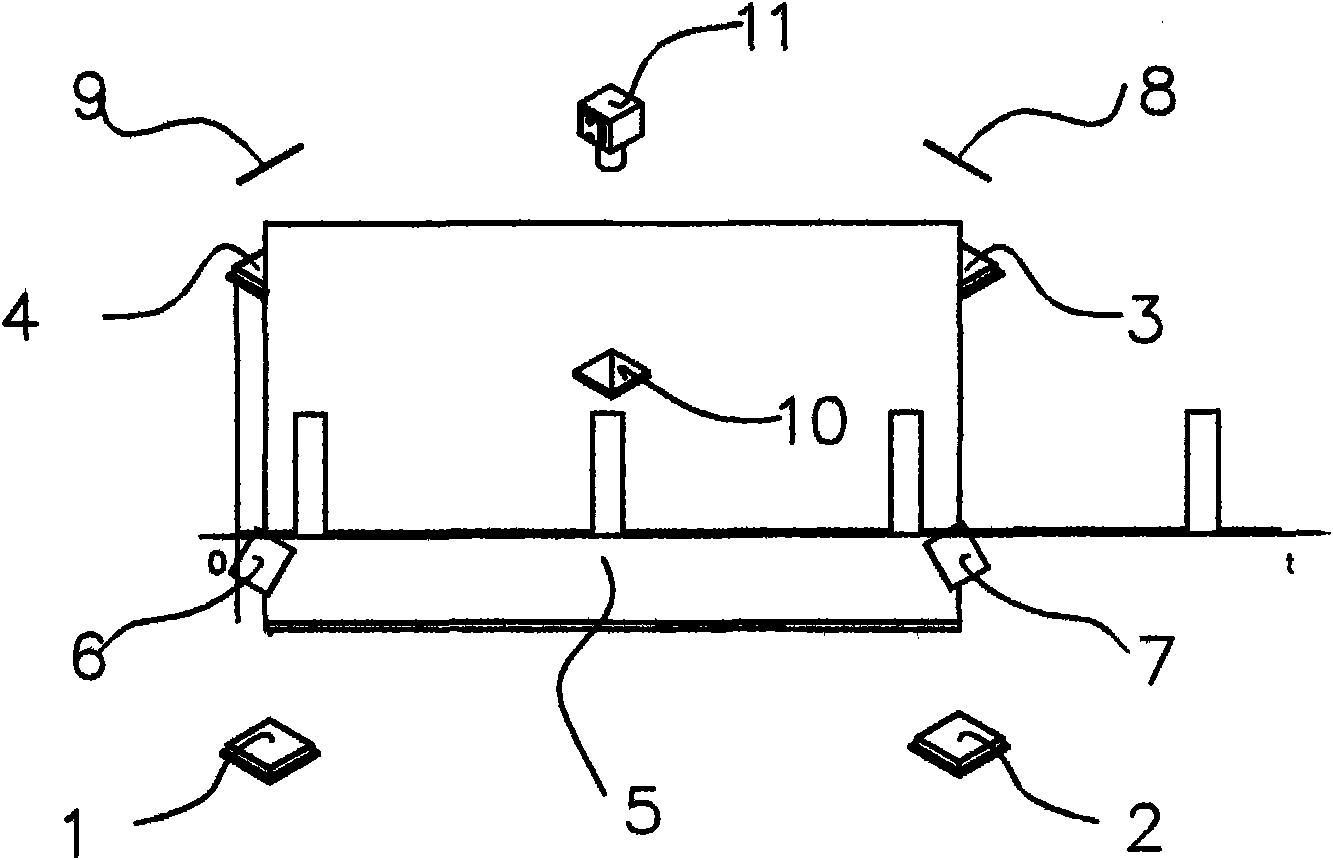

[0033] see Figure 1 to Figure 5 , a machine vision-based online data measurement method for a regular polygonal measured object provided by an embodiment of the present invention includes a regular polygonal measured object 5, which includes the following steps:

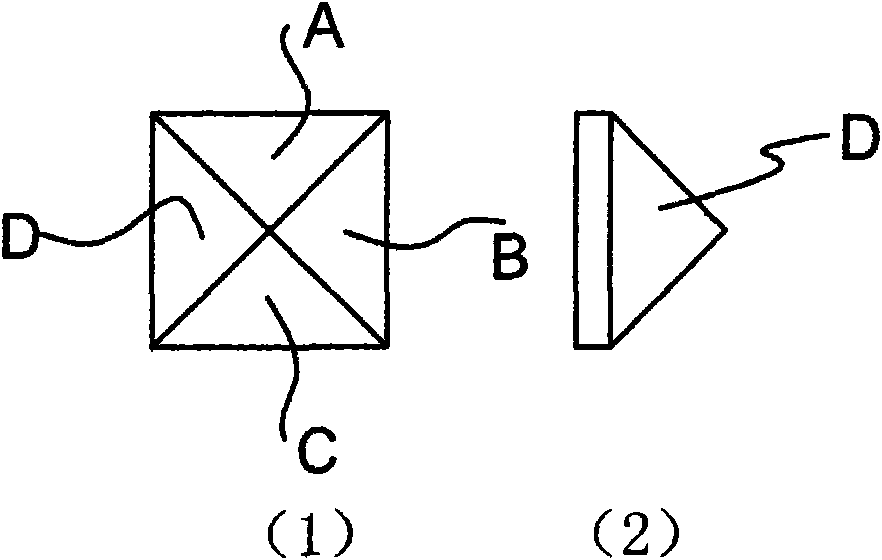

[0034] 1) A computer measurement control module and an on-site measurement module are set, and the two are connected to each other and can communicate interactively; The electronic camera device 11 of transmission function, and be arranged on this electronic camera device 11 lens imaging areas just below a regular polyhedron central reflective prism 10, and with each reflective surface A, B, C, D etc. of this regular polyhedral central reflective prism 10 one-to-one corresponding polygonal angle mirrors 9, 8, 7, 6 that are tall, equidistant, parallel, and oppositely arranged, and in the reflection area directly below each polygonal angle mirror 9, 8, 7, 6, Correspondingly, a backlight source 4 , 3 , 2 , 1 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com