On-line data measuring method for regular polygon measured object based on machine vision and system

A regular polygon, data measurement technology, used in measurement devices, instruments, optical devices, etc., can solve the problems of picture distortion, high error rate, limited pixel value, etc., and achieve the effect of eliminating asynchronous errors.

Active Publication Date: 2011-01-05

广东科视光学技术股份有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, for the harsh environment on the production line of many regular polygonal products such as ceramic tiles, there is no suitable online measurement method for product size, flatness, etc., and almost all of them are carried out manually and offline with vernier calipers. Low, affecting production capacity, and high error rate, prone to uncertain factors such as unstable detection quality

However, foreign testing equipment is often blocked due to technology or high cost. It is difficult for domestic enterprises to obtain suitable equipment or must bear high equipment costs.

At present, some scientific research institutes and enterprises in China have conducted research on the measurement methods of regular polygonal products (measured objects) such as ceramic tiles, and proposed three measurement methods: one is to use four cameras installed on the regular polygonal measured object. Shoot directly on the four diagonal corners, but this method is not suitable for online measurement, the main reason is that the four cameras cannot guarantee complete synchronization, and the regular polygon measured object moves at high speed, and the regular polygon measured object will be displaced after a delay of 1ms It is about 0.4mm, which cannot meet the measurement accuracy requirements. It is difficult to adjust and calibrate at the same time, and the practicability is poor; There is asynchronous camera acquisition, which cannot meet the accuracy requirements; the third method uses a camera to capture the entire format of the regular polygon measured object for measurement. Due to the limited pixel value of the camera, the pictures obtained by shooting the entire regular polygon measured object are often seriously distorted , can not meet the measurement accuracy requirements

Therefore, with regard to the above technical problems, in the field of measuring regular polygonal objects such as ceramic tiles, no automatic data measuring equipment for online regular polygonal objects to meet production needs has been developed in China at present.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

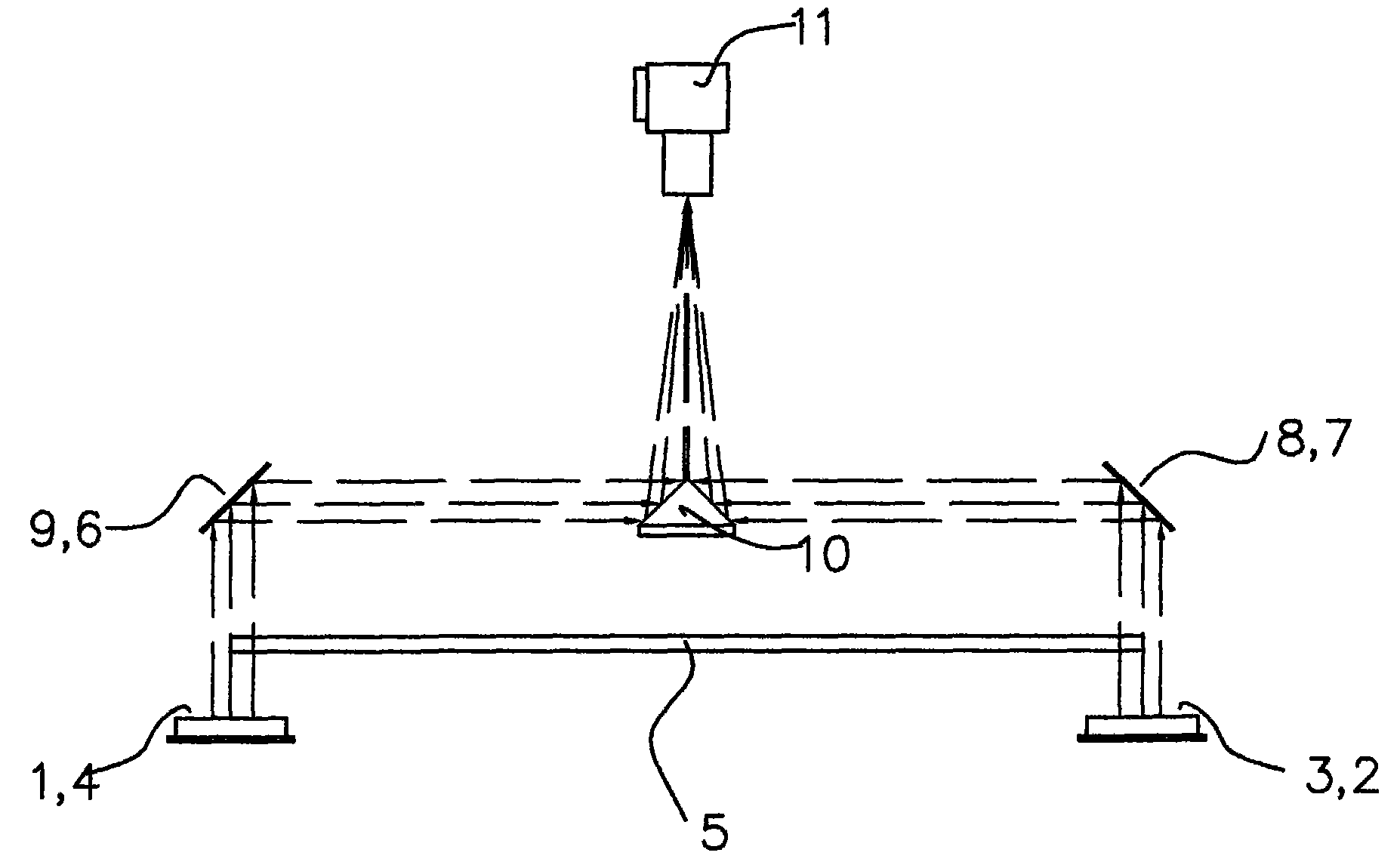

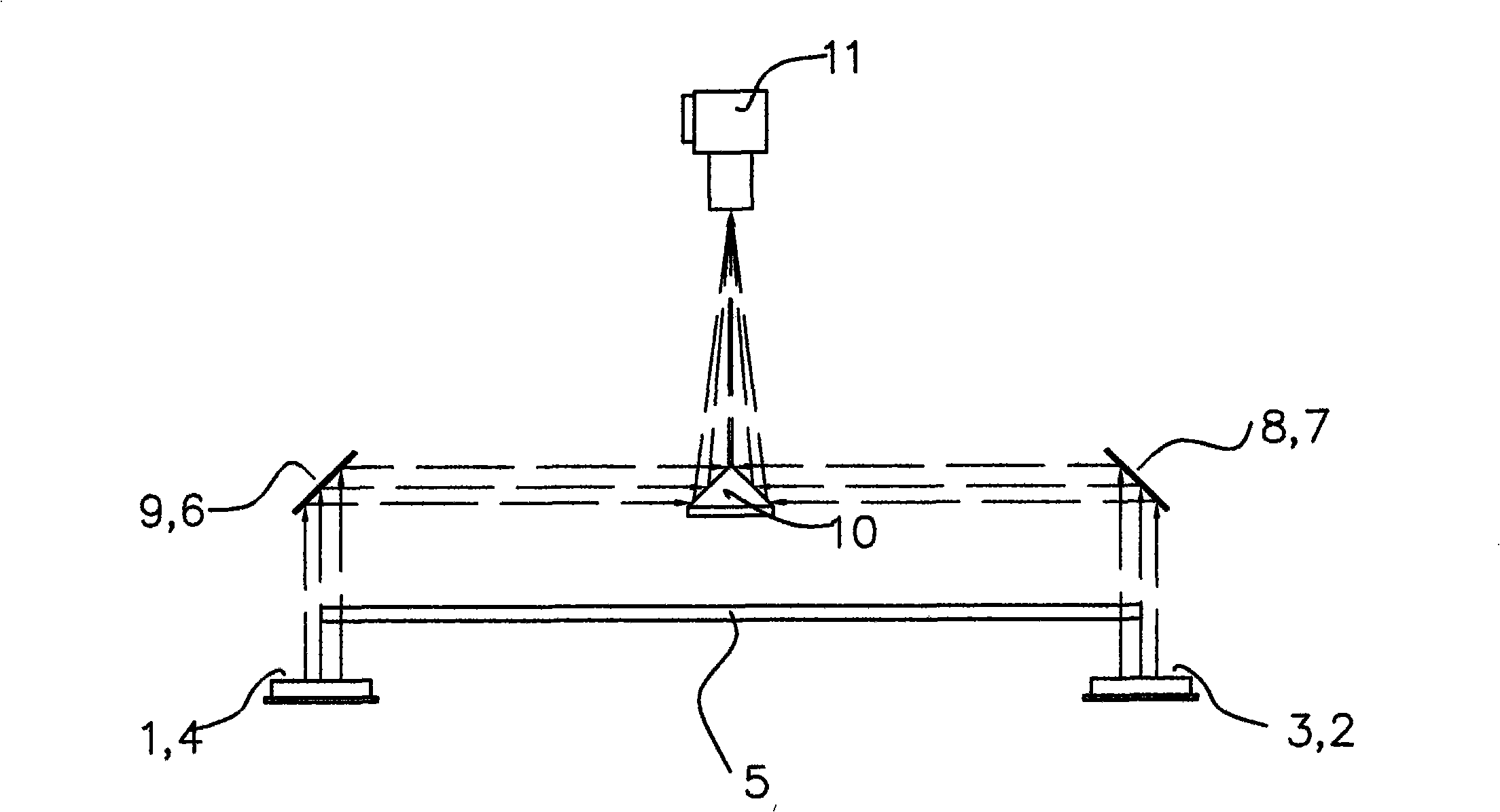

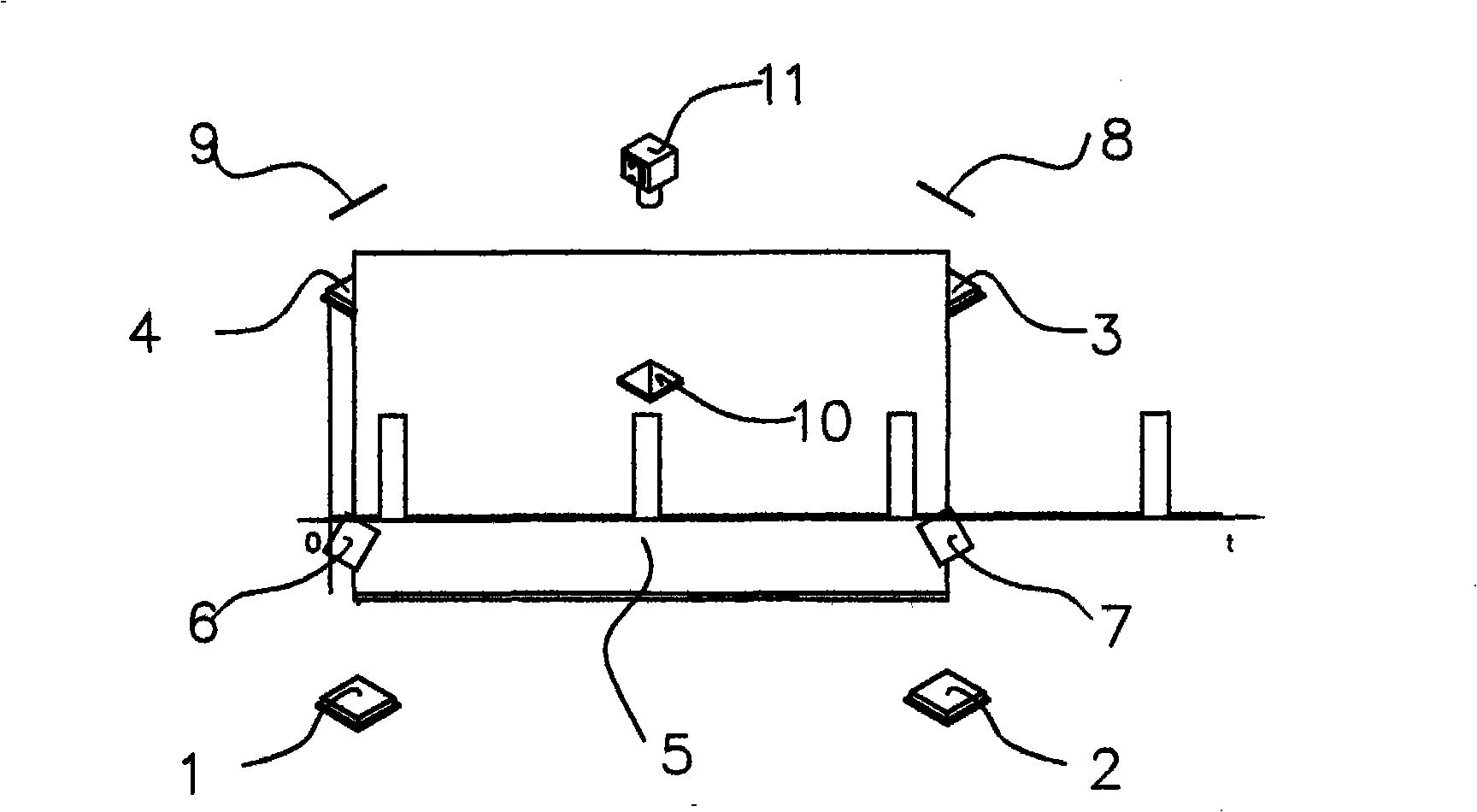

The invention discloses an on-line data measuring method for a regular polygon measured object based on machine vision, which is characterized in that the method comprises the following steps: (1) a computer measurement control module is set and connected with a field measurement module which comprises an electronic image pickup device, a regular polygon central reflector prism, a plurality of diagonal reflectors and backlights; (2) the regular polygon measured object is arranged between the regular polygon central reflector prism and each backlight; after the backlight is lightened, each diagonal reflector reflects the projection to the camera area of a camera head lens by the central reflector prism; (3) the camera head lens simultaneously collects and images projection optical signals,converts the projection optical signals into electrical signals or data which is transported to the computer measurement control module; (4) the computer measurement control module obtains the data results obtained by measuring the measured object by operation. The invention also discloses a system for realizing the method.

Description

Method and system for online data measurement of regular polygon measured objects based on machine vision technical field The invention relates to an online data measurement method of a regular polygon measured object based on machine vision, specifically an automatic online measurement method integrating image technology, optical path conversion technology, and machine vision technology, which is applied to a regular polygon measured object production line Online data measurement on . Background technique At present, there are more than 2,000 production lines of regular polygonal products such as ceramic tiles in China, which mass-produce regular polygonal products such as ceramic tiles of various types and sizes, and many of the high-quality regular polygonal products require precise dimensions and high flatness. For regular polygonal products such as tiles with a width of 600mm and 800mm, the actual size error is required to be controlled within ±0.3mm, and for measurin...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01B11/02G01B11/26G01B11/30G01B11/00

Inventor 王华

Owner 广东科视光学技术股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com