Preservative film cutting device

A technology of cutting device and plastic wrap, applied in transportation and packaging, metal processing, sending objects, etc., can solve the problems of inconvenient use, difficult to use, difficult to tear the plastic wrap, etc., and achieve the effect of simple interlocking relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

[0021] Before the present invention is described in detail, it should be noted that in the following description, similar elements are denoted by the same reference numerals.

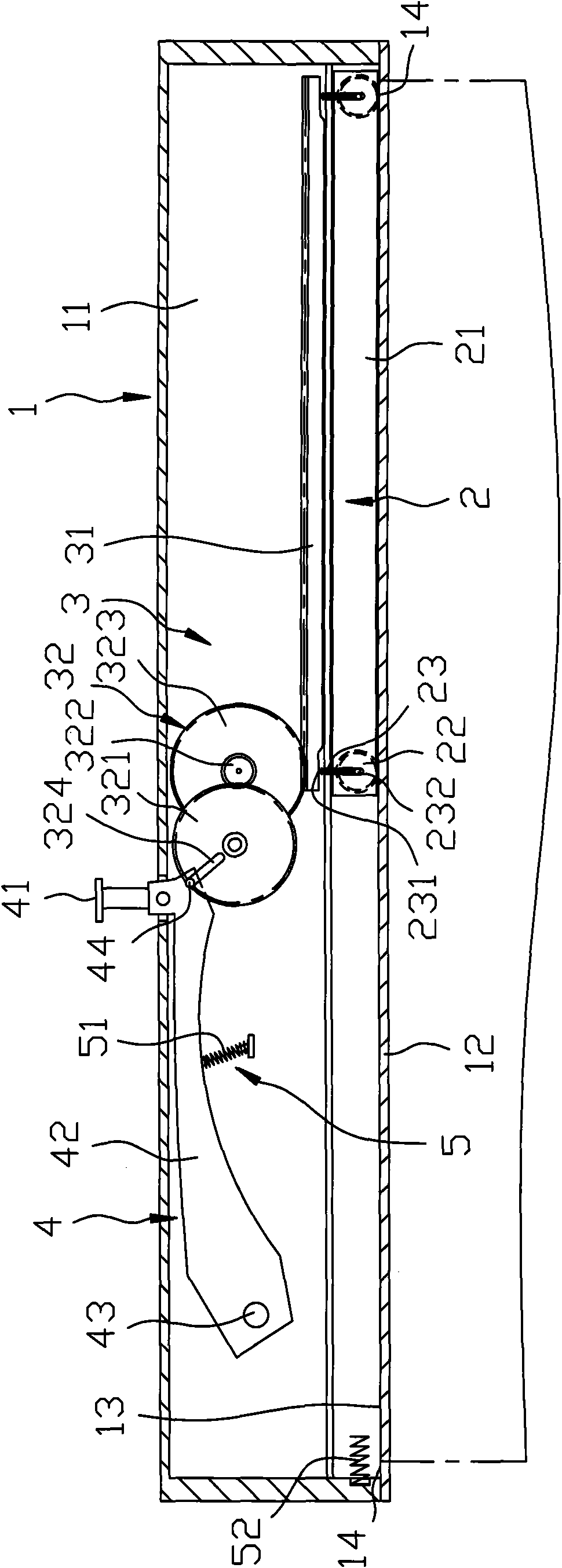

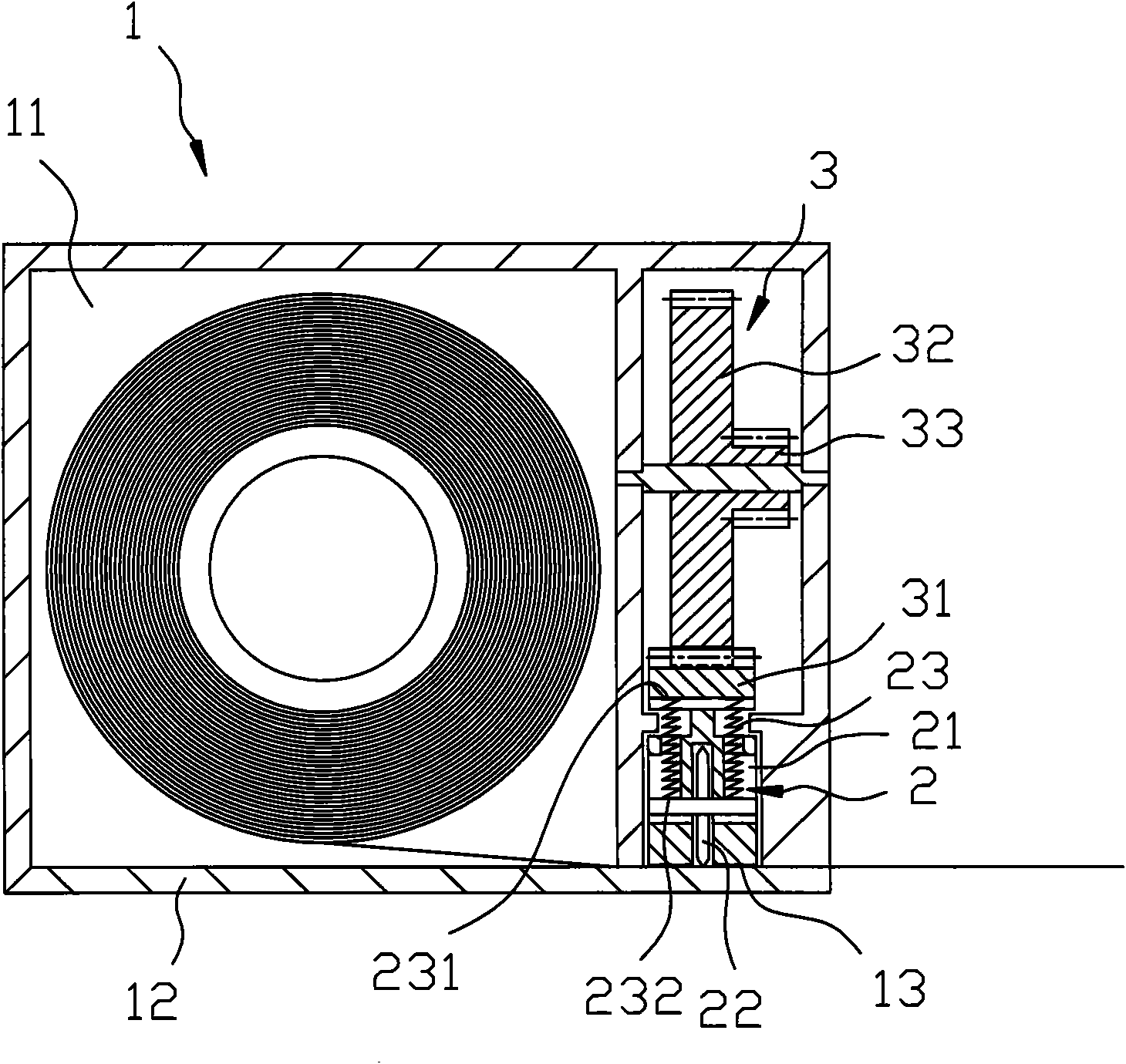

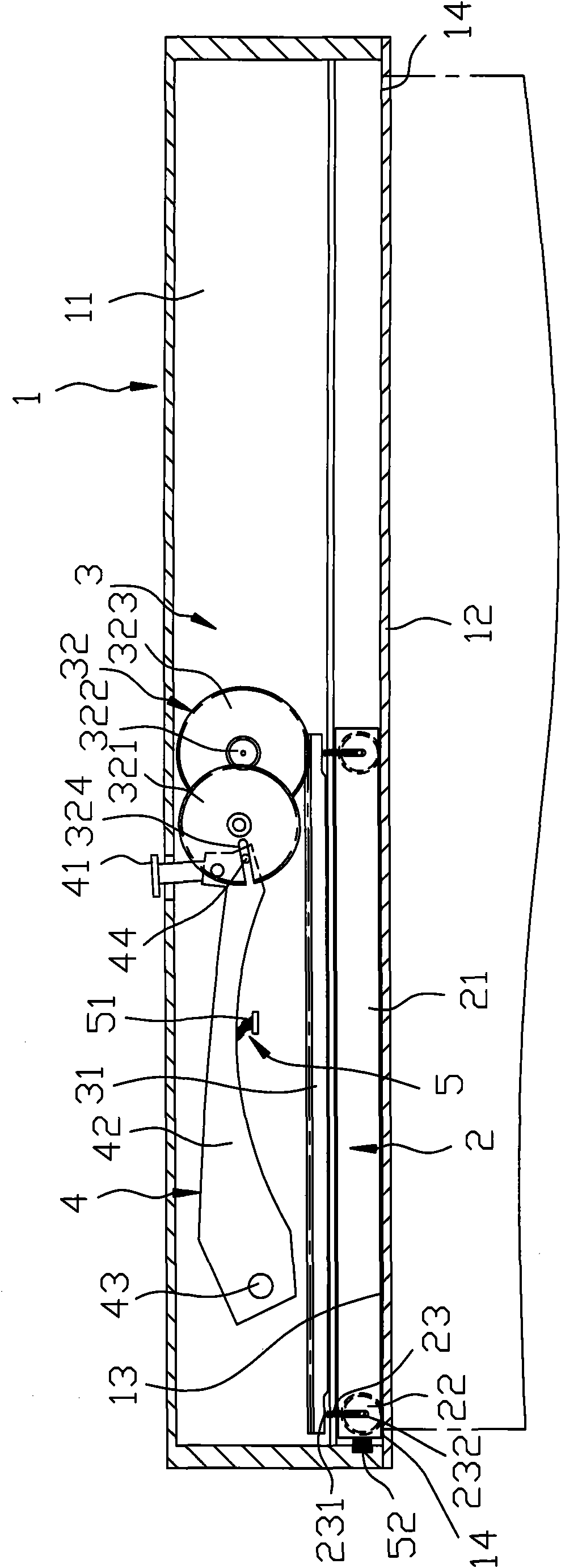

[0022] refer to figure 1 and figure 2 , The first preferred embodiment of the plastic wrap cutting device of the present invention includes a housing 1 , a cutting unit 2 , a transmission unit 3 , a starting unit 4 and a restoring unit 5 .

[0023] The housing 1 includes a chamber 11 for accommodating a roll-shaped plastic wrap, a cover 12 covering the opening of the chamber 11, a side edge 13 positioned at the opening of the chamber 11, and two Two endpoints 14 located at both ends of the side edge 13.

[0024] The cutting unit 2 is mounted on the housing 1 and includes a knife seat 21 linearly displaced along the side edge 13 of the housing 1 , a knife seat 21 mounted on the knife s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com