Pouring gate structure of mould in APG process

A technology of molds and gates, which is applied in the field of gates, can solve the problems of easy sink marks, scrapped insulation products, and difficulty in processing, and achieve the effects of delaying part curing, reducing product deformation, and improving pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

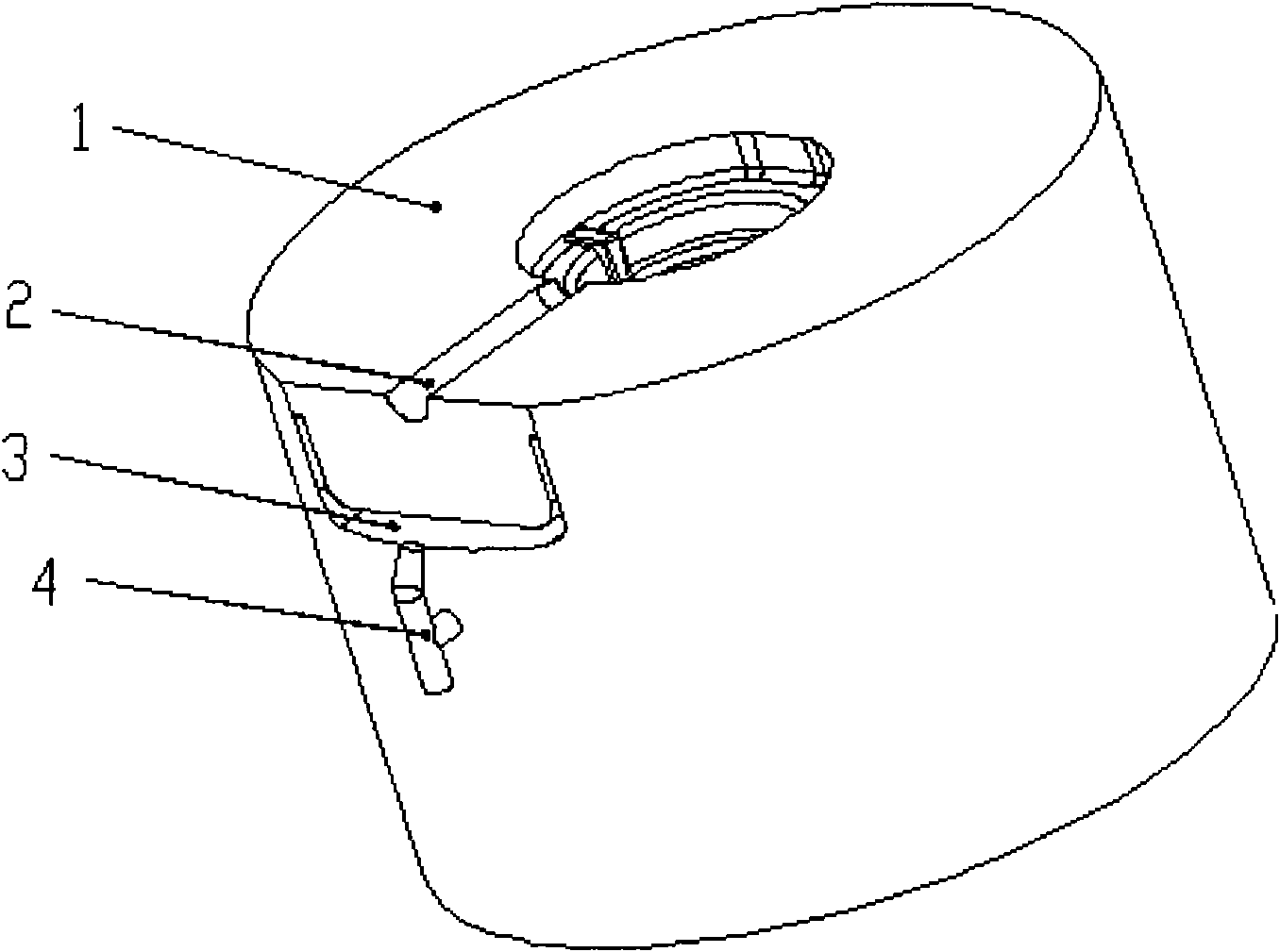

[0010] Depend on figure 1 It can be seen that the present invention includes: a body 1; a gate 2 is included on the body 1; a cooling tank 3 is arranged at the entrance of the gate 2; a blowing nozzle aimed at the cooling tank 3 is also included 4.

[0011] The invention ensures that the injection nozzle of the mold is always at a relatively low temperature during the entire injection process, and avoids sink marks and pores (internal and external pores) of the thermosetting material product caused by the early curing of the epoxy material at the feeding port. And other forming defects that cannot be solved by process adjustment.

[0012] The invention adds air-cooling grooves and blowing nozzles on the mold to cool the mold runner and gate, reduce the excessive absorption of mold heat by the epoxy resin in the reaction stage, thereby reducing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com