Retractable unit horizontal hard protection

A hard protection and unitized technology, which is applied in the direction of construction, building structure, and building material processing, can solve the problems of high safety risks and inconvenient construction of horizontal hard protection, so as to improve safety and reduce the risk of falling objects , Ease of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

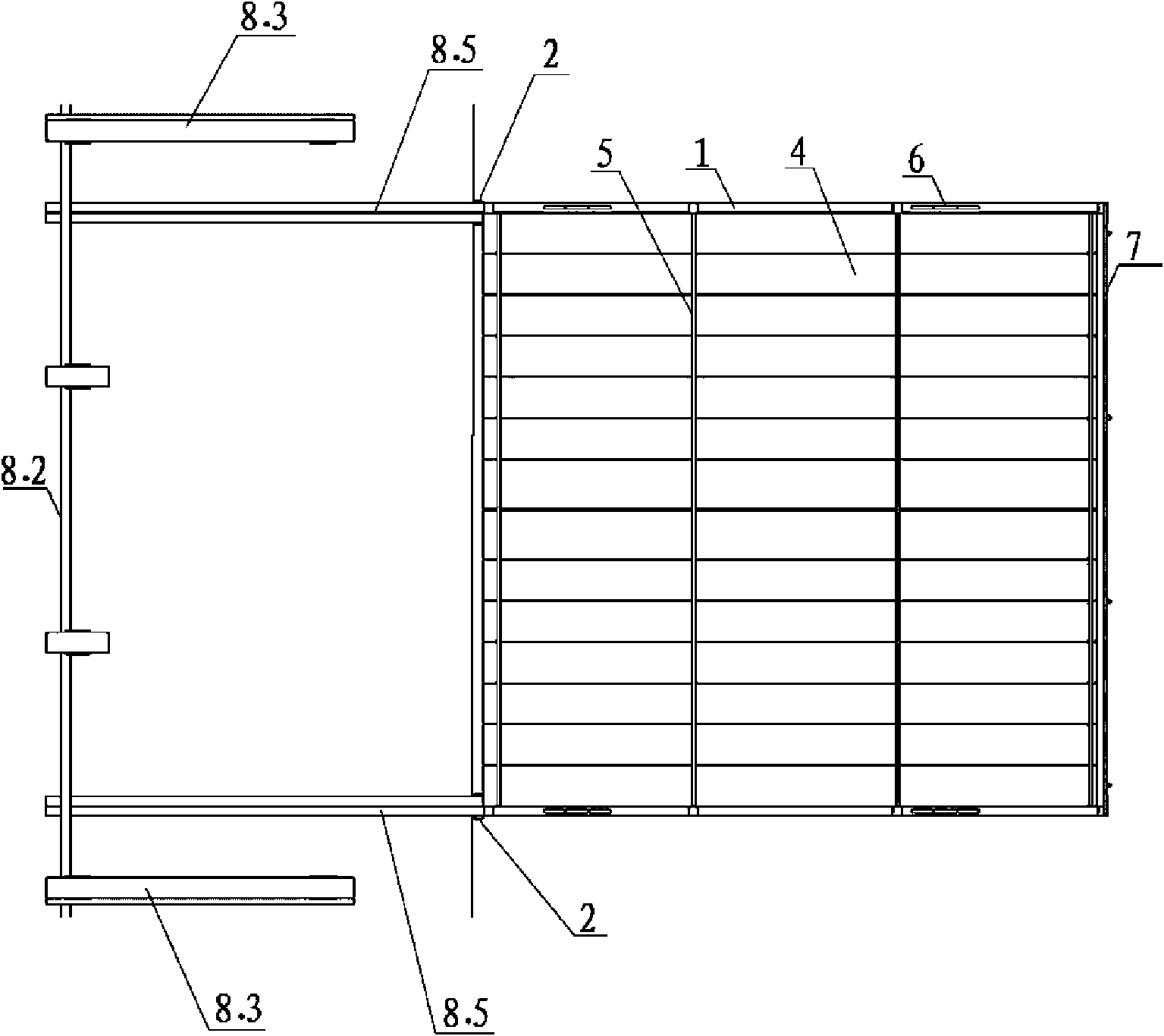

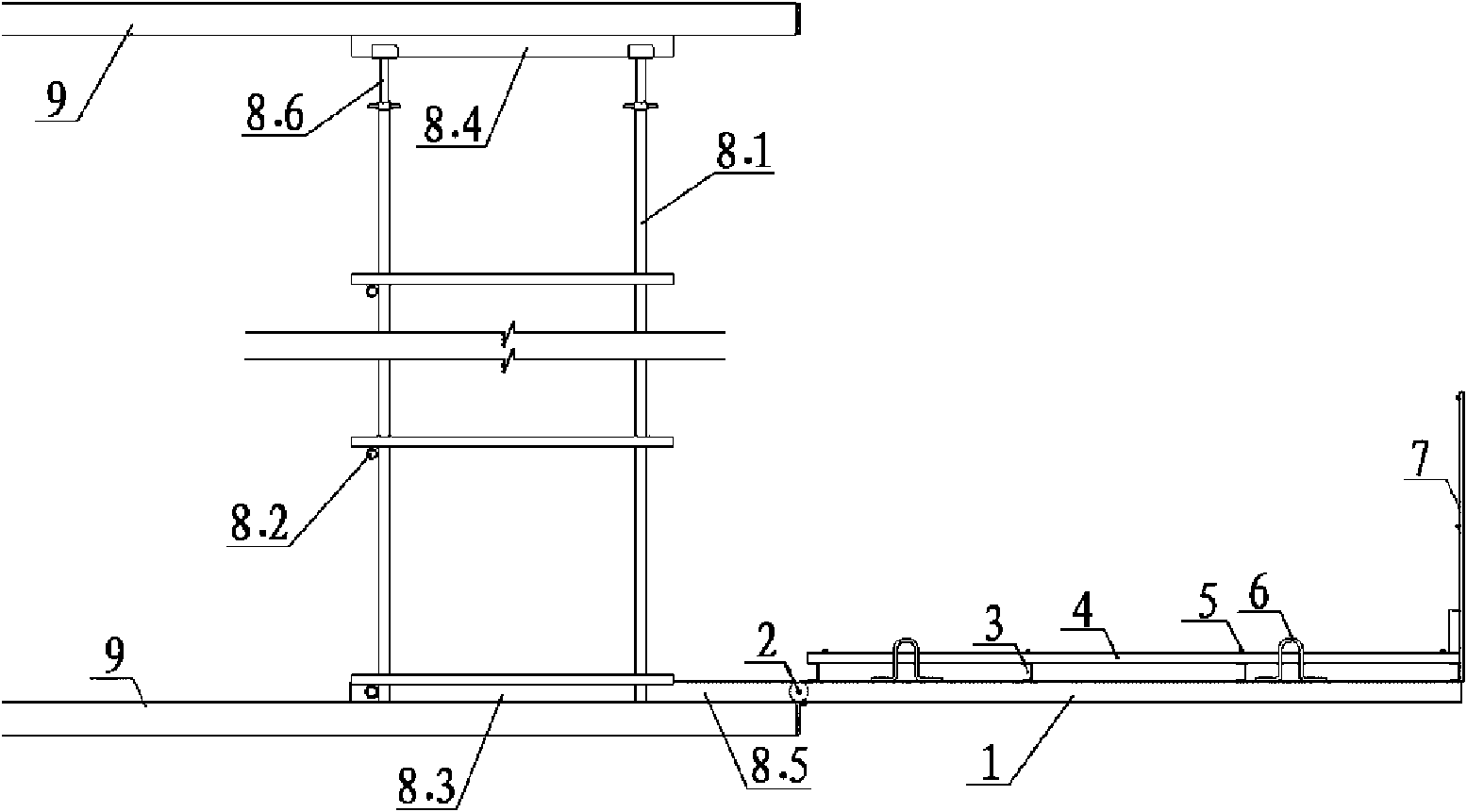

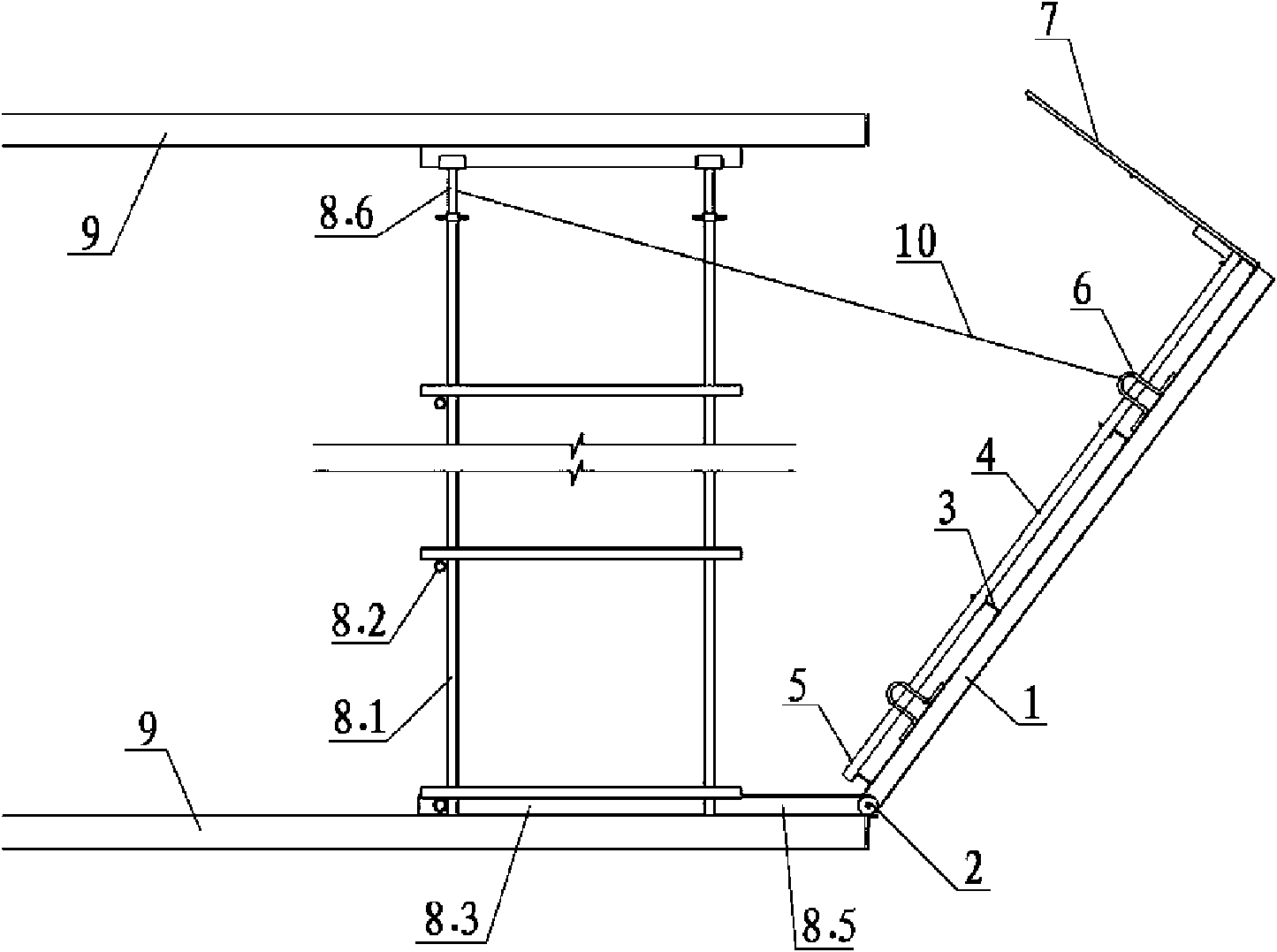

[0022] see figure 1 As shown, this retractable unit type horizontal hard protection includes a protective chassis and a protective railing, and the outer side of the protective chassis is vertically connected with the protective railing 7, and the protective chassis is composed of two main beams 1 and a secondary beam. 3 is handed over and formed, and the base plate 4 is laid on the protective chassis, and the base plate is provided with a transverse rib 5; the main beam and the secondary beam are shaped steel, and the protective railing can be made of? 12 steel bars are welded, and the transverse rib 5 of the protective underframe can be four? 12 steel bars. The base plate laid on the protective underframe can be a plank.

[0023] The inner end of the main beam 1 is hinged by the rotating shaft 2 and the bottom outer side of the interlayer steel support frame 8 connected between the two-story structural floors 9. Two suspension rings 6 are respectively fixed on the outside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com