Constant-temperature low-noise oil sump tank of engine

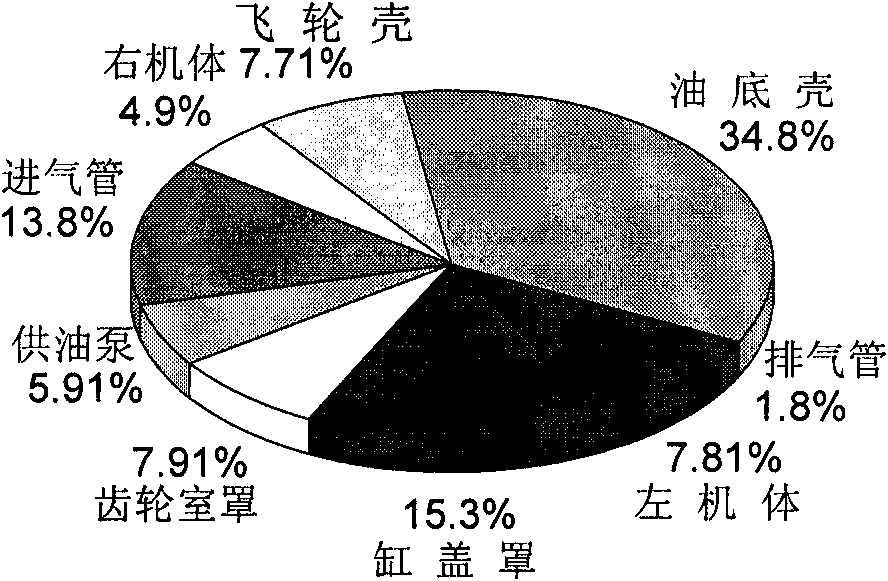

A technology of oil pan and engine, which is applied in the direction of engine components, machine/engine, engine lubrication, etc. It can solve the problems of damping performance decline, noise rising instead of falling, and high lubricating oil temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

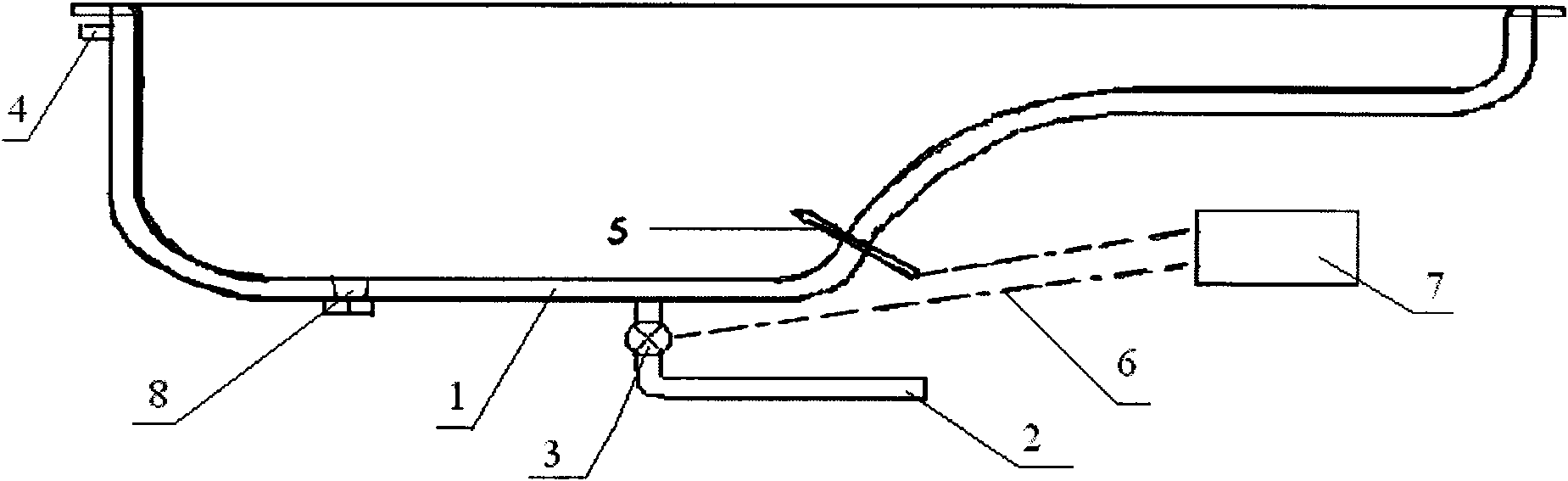

[0008] The structural principles of the present invention will be further described below in conjunction with the embodiments. Engine constant temperature and low noise oil pan, with oil pan main body, solenoid valve, temperature sensor, controller, and transmission cable, etc. The main body 1 of the oil pan is designed as a double-layer sandwich structure, the inner layer is a common steel plate, and the outer layer is a composite damping steel plate. The coolant circulates in the interlayer, and the outer side of the oil pan main body 1 is coated with damping glue. The bottom of the main body of the oil pan is provided with a coolant inlet pipe 2 and a solenoid valve 3; the upper end of the main body of the oil pan is provided with a coolant outlet 4; the lower end of the main body of the oil pan is provided with a temperature sensor 5; the temperature sensor 5 and the solenoid valve 3 Connected with the transmission cable 6 and connected with the controller 7 (such as fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com