Hydraulic valve control device and method for checking a hydraulic valve control device

A technology for controlling equipment and hydraulic valves, applied in mechanical equipment, general control systems, electrical program control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

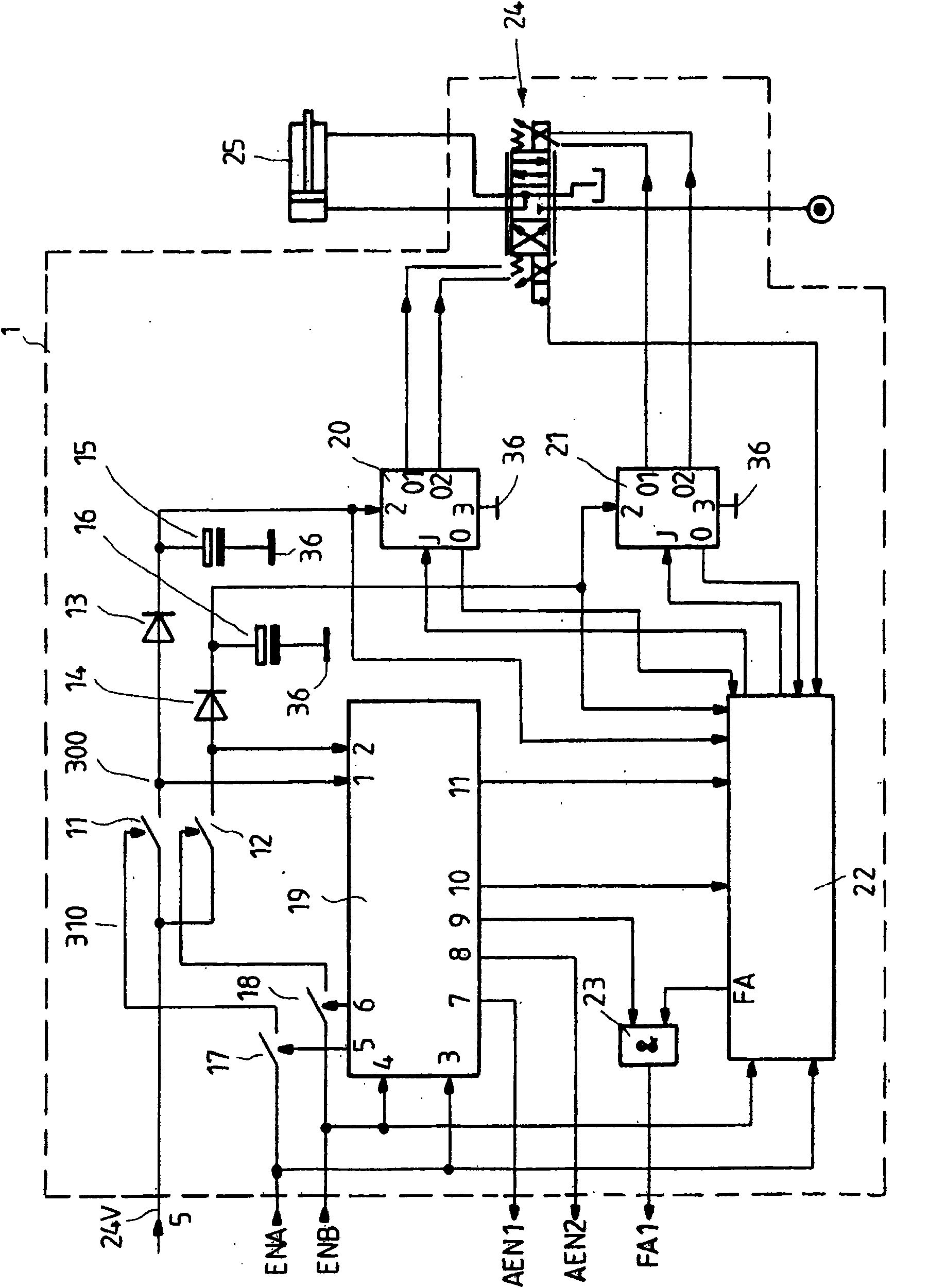

[0067] figure 1 The design of the hydraulic valve control device 1 according to the invention is shown schematically, which has an integrated hydraulic valve 24 . The integration means that the hydraulic valve 24 and the valve electronic device for controlling the hydraulic valve 24 are all installed in one housing together.

[0068] The function of the hydraulic valve 24 is to drive the hydraulic cylinder 25 located outside the casing. The hydraulic valve is designed as a proportional valve in which a magnetic field is generated by means of a coil. This magnetic field moves the spool in the valve according to the current passing through the coil. In other embodiments, other current-driven actuators can also be used instead of coils.

[0069] The hydraulic valve control device 1 comprises a first output stage 20 , a second output stage 21 and an output stage controller 22 . The output stages 20 and 21 each have an input I, two outputs O1 and O2 , a feedback output O, a fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com