Fluid pipe monitoring and managing system

A fluid pipeline, monitoring and management technology, applied in pipeline systems, material defect testing, gas/liquid distribution and storage, etc., can solve problems such as delayed rescue timing, resource waste, and failure to notify in time, and achieve remote monitoring and Simple management, simple structure, and accurate judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

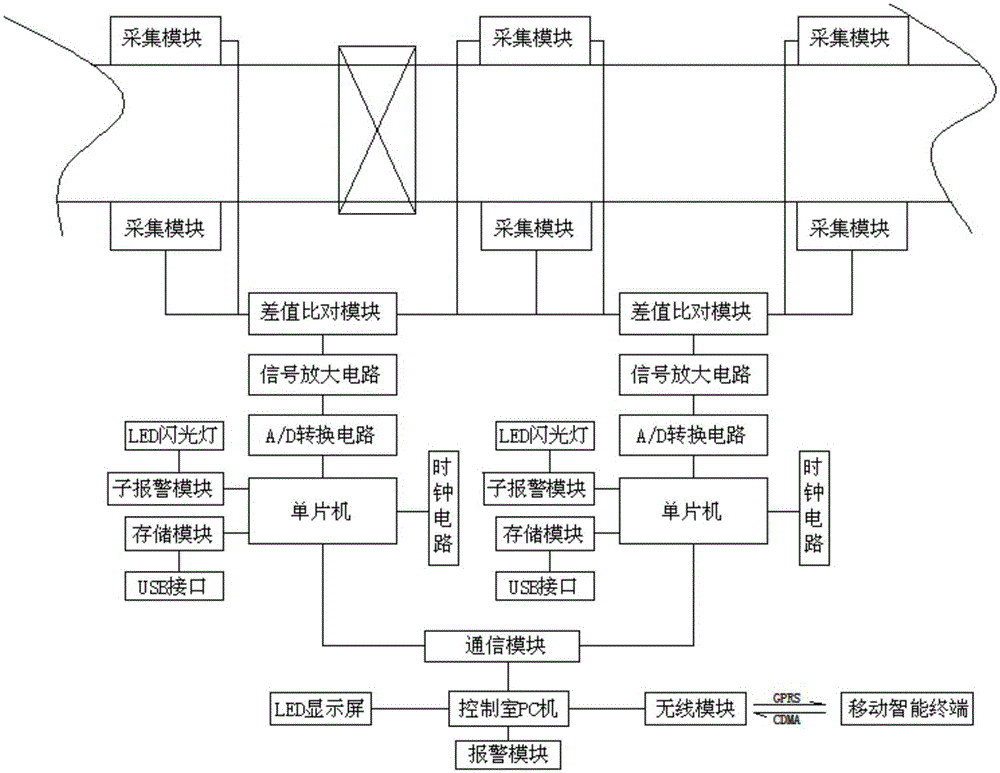

[0019] like figure 1 As shown, a fluid pipeline monitoring and management system includes an acquisition module, a difference comparison module, a signal amplification circuit, an A / D conversion circuit, a single-chip microcomputer, a clock circuit, a sub-alarm module, a storage module, a communication module, and a PC in the control room , LED display, alarm module, wireless module and mobile intelligent terminal.

[0020] There can be multiple acquisition modules, and they are installed on the fluid pipeline at intervals of 2000m-3000m, and 2-3 acquisition modules can also be installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com