Iron ore powder mineral dressing process

A technology of iron ore powder and process, which is applied in the field of iron ore powder beneficiation process, can solve the problems of insufficient classification operation, waste economy, wide particle size of grinding operation, etc., and achieve significant economic and social benefits, magnetic separation Efficiency improvement and productivity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

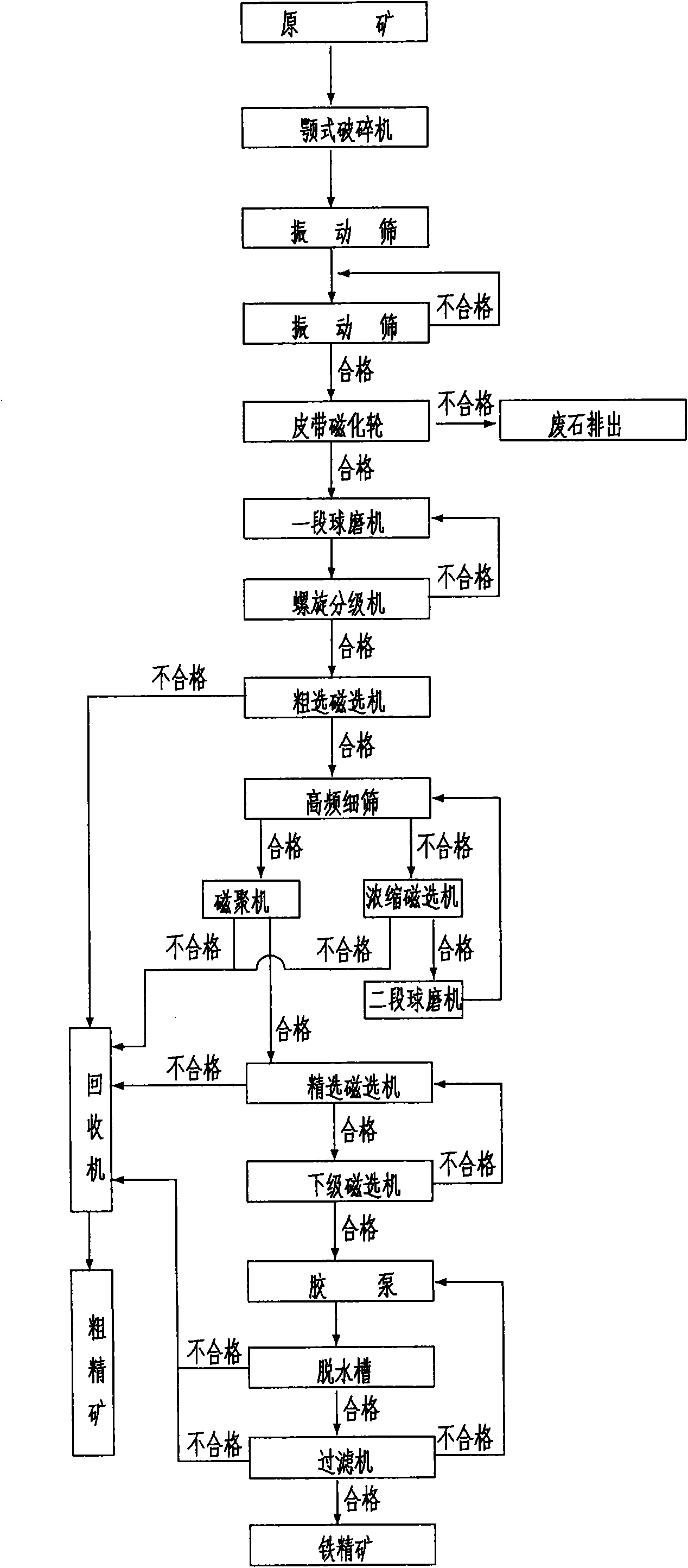

[0026] As shown in the figure, the present invention comprises the following steps:

[0027] 1) Primary crushing: Feed by feeding truck, crushed by the primary crusher, the primary crusher adopts jaw crusher, and the particle size of the iron ore crushed by the primary crusher is 7-15cm;

[0028] 2) Secondary crushing: The iron ore after the primary crushing is sent to the vibrating screen for primary selection, and the coarse iron ore on the screen is sent to the secondary crusher for secondary crushing. The secondary crusher adopts a cone crusher , the iron ore after the secondary crushing is sent back to the vibrating screen through the belt conveyor I for re-scree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com