Method for manufacturing metal composite plates by stirring friction

A metal composite plate and friction stir technology, which is applied in the direction of manufacturing tools, metal processing equipment, non-electric welding equipment, etc., can solve the problems of narrow application range, complicated process, uneven welding layer surface, etc., achieve smooth surface and wide application range , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

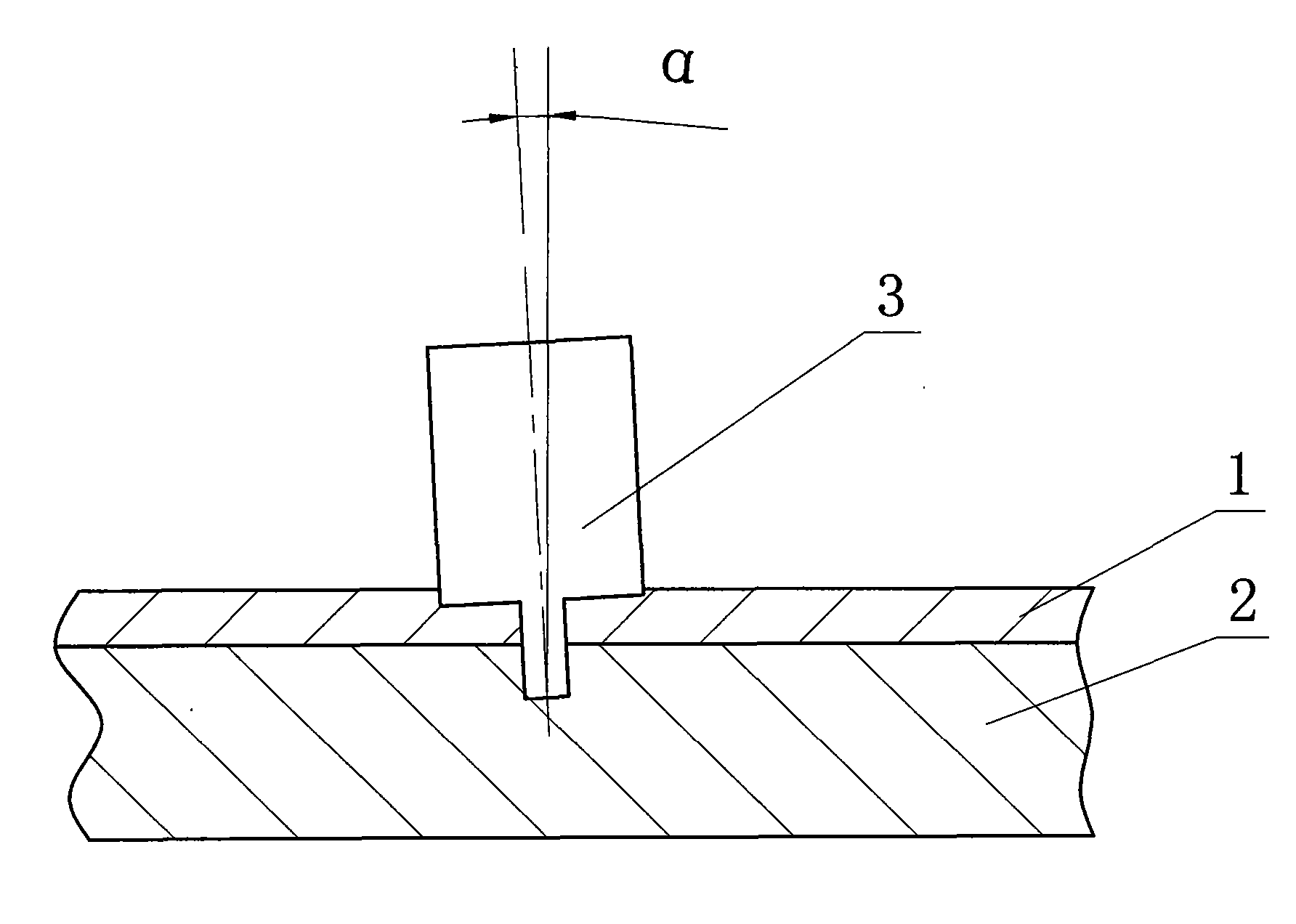

[0010] Specific implementation mode one: as figure 1 As shown, the method for manufacturing metal composite panels by friction stir described in this embodiment is realized according to the following steps:

[0011] Step 1. Place the metal cladding plate 1 on the upper surface of the metal substrate 2, and fix the metal cladding plate 1 and the metal substrate 2 on the workbench. The thickness of the metal cladding plate 1 is 0.3-10 mm, and the thickness of the metal substrate 2 is 0.3 ~ 100mm;

[0012] Step 2, place the stirring head 3 at any position on the upper surface of the metal cladding plate 1, the angle a between the stirring head 3 and the vertical direction is 0-10°, and the stirring head 3 rotates at 200-3000 rpm Pass through the metal cladding plate 1 and penetrate into the metal substrate 2, the speed of the stirring head 3 is 1-5mm / minute, and the depth of penetration into the metal substrate 2 is 0.1mm-100mm;

[0013] Step 3. When the stirring head 3 reaches...

specific Embodiment approach 2

[0015] Specific implementation mode two: as figure 1 As shown, the metal cladding plate 1 described in step 1 of this embodiment is an aluminum plate or an aluminum alloy plate, and the metal substrate 2 is a magnesium plate or a magnesium alloy plate. The material of the composite panel can be selected according to the specific application. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0016] Specific implementation mode three: as figure 1 As shown, the metal cladding plate 1 described in Step 1 of this embodiment is a magnesium plate or a magnesium alloy plate, and the metal substrate 2 is a stainless steel plate. The material of the composite panel can be selected according to the specific application. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com