Balance chamber supercharged piston fast reposition air cannon

A pressurized piston and balance chamber technology, applied in the field of fast-reset air cannons with pressurized pistons in the balance chamber, can solve problems such as easy crushing of the return spring, easy damage of the material entering the air cannon, and easy damage to the piston to achieve pressure and impact The effect of force reduction, prolonging service life and speeding up reset speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

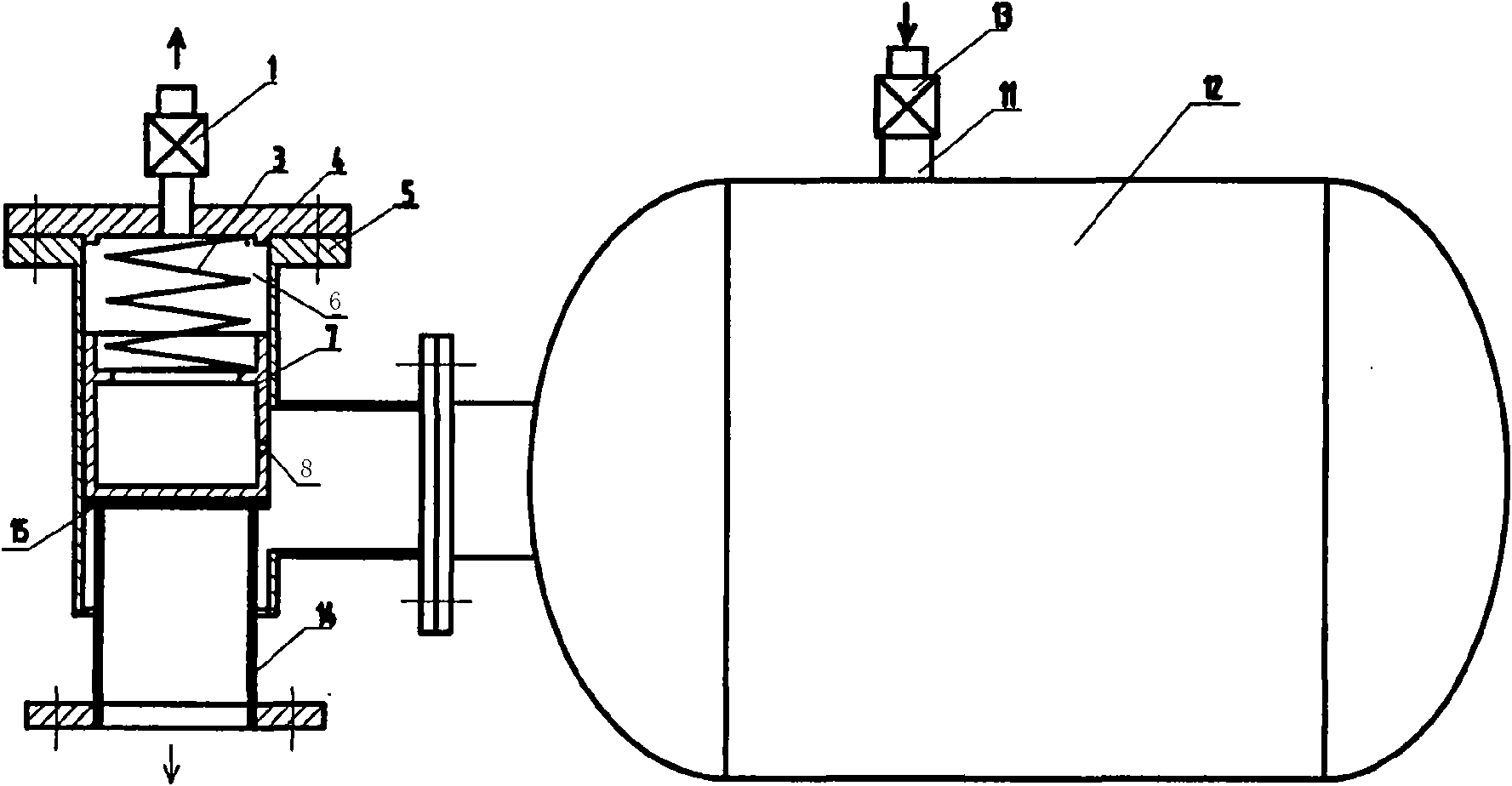

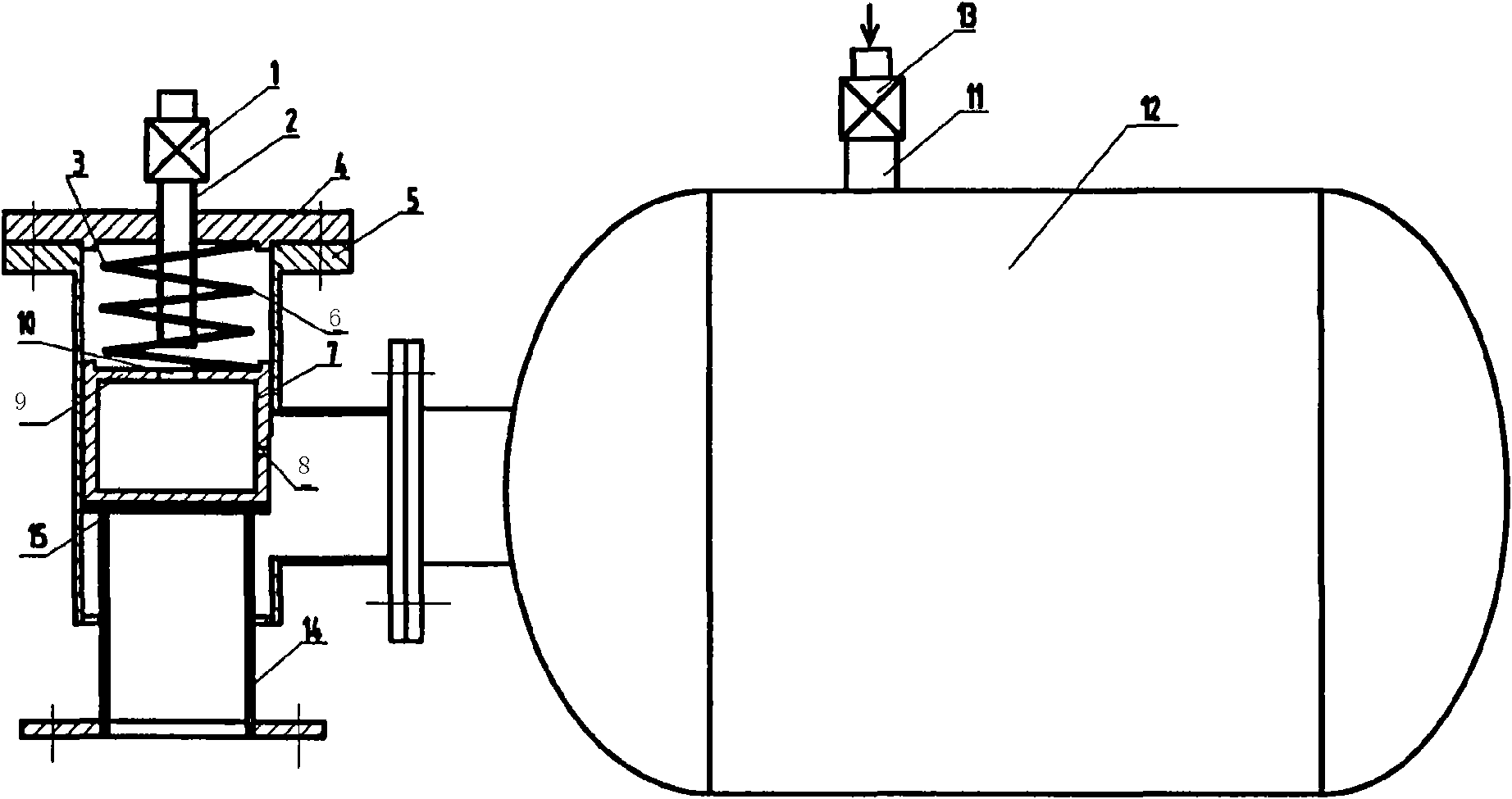

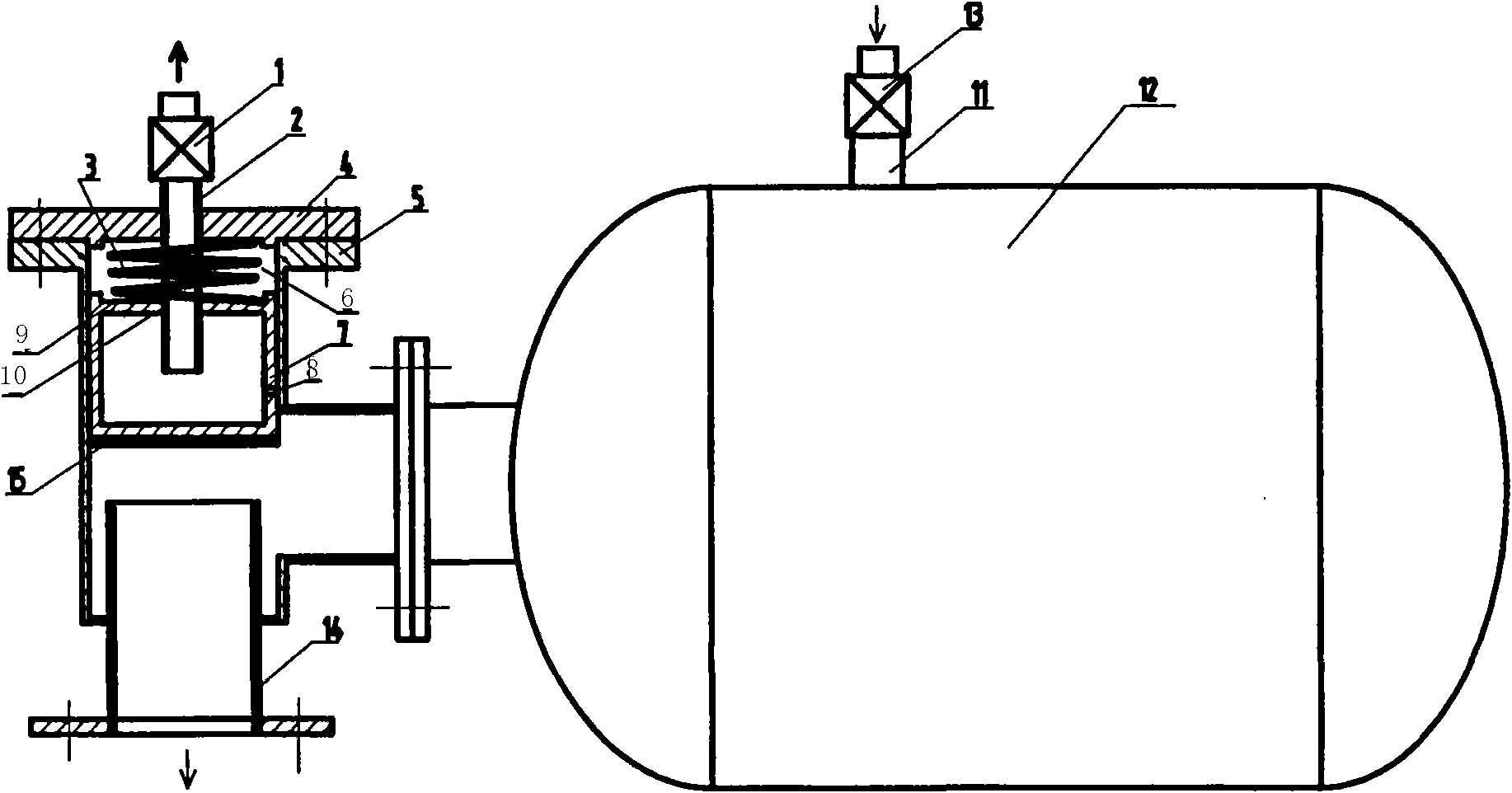

[0013] The structural connection form of the present invention will be further described below in conjunction with the accompanying drawings:

[0014] Such as figure 2 , 3 Shown: the balance chamber booster piston quick reset type air cannon of the present invention includes an air storage tank (12), an air intake pipe (11) connected with the air storage tank, and a two-way valve for controlling the air intake of the air storage tank (13) The gas storage tank is equipped with a piston cylinder (5), a piston (7), a piston cylinder end cover (4), a pressurizing chamber (6) located in the piston cylinder, and a return spring (3). Piston-type sealed exhaust control mechanism, the bottom surface of the piston is in contact with the nozzle of the exhaust nozzle (10) and sealed, and the side wall of the piston (7) is provided with a backflow hole connecting the pressurizing chamber (6) and the gas storage tank (12) (8), in which: the end cover of the piston cylinder is equipped with a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com