Supported polyolefin catalyst, preparation and application

A polyolefin catalyst and supported technology, which is applied in the field of supported polyolefin catalyst and its preparation and application, can solve the problems of reduced activity and great influence of homogeneous catalyst loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

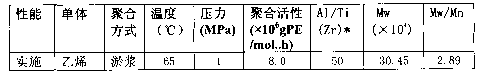

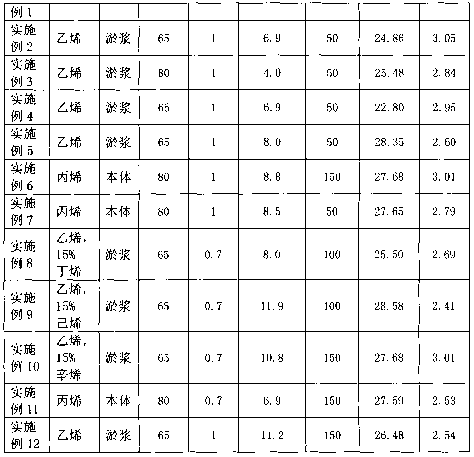

Examples

Embodiment 1

[0032] Bis-(n-butyl-cyclopentadienyl)zirconium dichloride supported catalyst

[0033] 1. Preparation of spherical amorphous zirconium phenylphosphate: 23gZrOCl2 8H 2O was dissolved in 240ml deionized water to prepare a 0.3mol / l solution; 33g phenylphosphoric acid was dissolved in 210ml deionized water to prepare a 1.0mol / l phenylphosphoric acid solution; under stirring conditions, ZrOCl 2 The solution is slowly added dropwise to the phenylphosphoric acid solution to obtain a zirconium phenylphosphate gel; the mixed system is sealed in a reaction kettle, crystallized at 70° C. for 20 hours, centrifuged, and washed with deionized water to obtain a zirconium phenylphosphate wet gel. Take a small amount of zirconium phenylphosphate wet gel and measure the solid content to be 20%. The zirconium phenylphosphate wet gel was dissolved in a certain amount of deionized water to obtain 400 ml of zirconium phenylphosphate slurry with a solid content of 7%, and the obtained slurry was mol...

Embodiment 2

[0038] Bis-(n-butyl-cyclopentadienyl)titanium dichloride supported catalyst

[0039] 1. Preparation of spherical amorphous zirconium phenylphosphate: 5gZrOCl2 8H 2 O is dissolved in 47ml of deionized water, and 7g of phenylphosphoric acid is dissolved in 42 milliliters of deionized water to prepare a phenylphosphoric acid solution; under stirring conditions, the ZrOCl solution is slowly added dropwise to the phenylphosphoric acid solution to obtain a zirconium phenylphosphate gel; the mixed system is reacted The kettle was sealed, crystallized at 70° C. for 20 hours, centrifuged, washed with deionized water to obtain a zirconium phenylphosphate wet gel. The zirconium phenylphosphate wet gel was dissolved in a certain amount of deionized water to obtain 150 ml of zirconium phenylphosphate slurry with a solid content of 5%, and the obtained slurry was molded by a rotary spray dryer. Control the feeding rate of the peristaltic pump to 30ml / min, the speed of the nozzle to 25000 r...

Embodiment 3

[0043] Cyclopentadienyl indenyl zirconium dichloride supported catalyst

[0044] 1. Preparation of spherical amorphous zirconium phenylphosphate: 5gZrOCl2 8H2O was dissolved in 47ml deionized water, 7g phenylphosphoric acid was dissolved in 42ml deionized water to prepare phenylphosphoric acid solution; under stirring condition, ZrOCl 2 The solution is slowly added dropwise to the phenylphosphoric acid solution to obtain a zirconium phenylphosphate gel; the mixture is sealed in a reaction kettle, crystallized at 70° C. for 20 hours, centrifuged, and washed with deionized water to obtain a zirconium phenylphosphate wet gel. The zirconium phenylphosphate wet gel was dissolved in a certain amount of deionized water to obtain 150 ml of α-zirconium phenylphosphate slurry with a solid content of 4%, and the obtained slurry was molded by a rotary spray dryer. Control the feeding rate of the peristaltic pump to 20ml / min, the speed of the nozzle to 25000 rpm, and the temperature of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com